KnipBio CEO: ‘We really need more of everything’ for aquaculture feeds

Massachusetts-based biotechnology firm KnipBio is the first single-cell protein manufacturer targeting the aquafeed industry to earn Generally Regarded as Safe (GRAS) designation from the U.S. Food and Drug Administration (FDA), the company announced today.

CEO Larry Feinberg told the Advocate that KnipBio Meal (KBM) achieved GRAS designation after extensive feed trials conducted by an independent panel of experts. KBM is a protein-based aquafeed ingredient for salmonid (salmon, trout) and other carnivorous (or omnivorous) finfish species.

The approval process for animal feed ingredients, which in the company’s case took roughly two years from start to finish, is more rigorous than for food products for direct human consumption, he said.

“In some ways, according to FDA, they’re more stringent. The animals don’t speak for themselves, so they have to speak for them,” said Feinberg. “We have to show that it’s safe.”

“Microbial meals” from the biotechnology sector are becoming a viable feed ingredient as the aquaculture industry, on a global scale, looks to conserve and supplement natural marine resources like fishmeal and fish oil. Feinberg said the only way for aquaculture to grow is to come up with sustainable feed solutions like single-cell proteins, insect meals and algae.

“We’re not out to replace fishmeal; it’s not going away. But what we really need is more of everything, and for [these new ingredients] to perform at an equal level or better than existing options. That’s the call to action,” said Feinberg, estimating that aquafeed manufacturers will need an additional 15 million tons of raw material to meet forecasted demand. He estimates the global aquafeed market to be worth more than $10 billion annually.

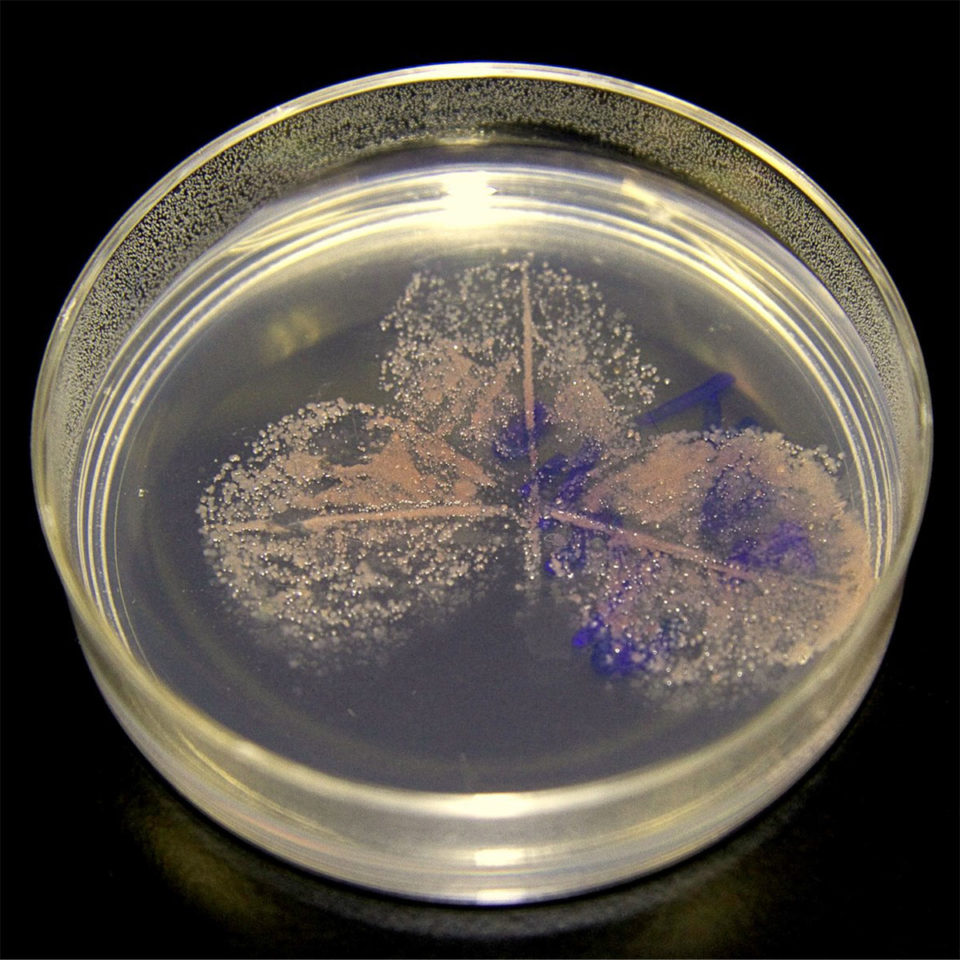

KBM is derived from the single-cell organism methylobacterium (Methylobacterium extorquens), a symbiont that grows on plant leaves. In KnipBio’s R&D lab and production facilities, the organism feeds on methanol, which is derived from natural gas, and then undergoes an industrial fermentation process in just a couple of days. The meal is the dried and processed form of the microbial biomass.

Feinberg describes KBM as a “protein plus” ingredient, as it can deliver custom formulations for fish producers based on species, such as astaxantin for salmonid feeds, or other specific dietary needs like taurine or amino acid composition.

The company’s ingredient has been making strides in feeding trials with both rainbow trout (Oncorhynchus mykiss) and Atlantic salmon (Salmo salar). Feinberg said salmonid products will likely be the first to market, followed closely by feeds for crustaceans, particularly shrimp. “It’s market-dependent,” he added.

GRAS designation, said Feinberg, was the fastest of several viable pathways. Self-designation, an alternative pathway to market than achieving GRAS status via the FDA’s Center for Veterinary Medicine (CVM), was an option but is far more “convoluted,” he said. Now that its base protein product has approval, he’s hoping that future SCP products the company develops will go through the process much more quickly.

“That was the strategy: base protein first. Then with other functional molecules, the novelty will be the combination, not the overall product. Astaxanthin is not new, it’s already approved,” he said. “We’re also optimistic that we can raise overall awareness of single-cell proteins in general.”

Feinberg, speaking this week at the F3 Companies Got Talent event in San Francisco, Calif., will argue that the federal approvals process takes too long and that there should be a form of “international reciprocity” among governments to avoid lengthy and costly waits for approvals in other countries.

“This is a complicated and onerous process. It’s slowing down the pace of innovation. We need to find the balance between innovation and safety,” he said.

The alternative ingredient industry, he added, is fragmented and needs to unify its voice to improve the process.

“We’re trying to solve a few hard things, all at the same time. Oils are a critical component. But just one component,” he said. “This [FDA] approval for our ingredient, which has only 10 percent inclusion [in feeds]. The other 90 percent is something other than what we’re bringing to the table.”

Follow the Advocate on Twitter @GAA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

James Wright

Editorial Manager

Global Aquaculture Alliance

Portsmouth, NH, USA

james.wright@aquaculturealliance.org

Tagged With

Related Posts

Aquafeeds

A new nutrient for aquaculture, from microbes that consume carbon waste

Biotechnology firm NovoNutrients aims to produce a line of nutraceutical aquafeed additives as well as a bulk feed ingredient that can supplement fishmeal. Its process includes feeding carbon dioxide from industrial gas to a “microbial consortium” starring hydrogen-oxidizing bacteria.

Responsibility

Aquaculture Exchange: Alan Shaw, Calysta

Turn fuel into animal food? Calysta can do that. The California biotech company is now hoping for greater buy-in from aquaculture, its target market. CEO Alan Shaw talks about the potential of FeedKind and its ambitious plans for 2016 and beyond.

Innovation & Investment

Aquafeed ingredient AlgaPrime wins GAA Innovation Award

A proliferation of alternative feed ingredients has allowed aquaculture to extend the natural resources it depends on. AlgaPrime, packed with the long-chain omega-3 fatty acid DHA, is being recognized as a game-changing innovation for aquaculture feeds.

Innovation & Investment

Algae innovators aim to freeze out early-stage shrimp losses

A greenhouse in Belgium believes its innovative shrimp feed product, made from freeze-dried microalgae, packs the necessary nutrients for the crustacean’s most vulnerable life stage: the first three days of its life.