Pathogen-resistant vannamei stocks selected for performance in highly intensive production systems

Faced with low market prices and the realization that shrimp farming is increasingly becoming a commodity-driven global agribusiness with low margins, farmers are exploring methods to improve productivity and reliability while lowering production costs. Combined with increasing the carrying capacity of culture systems, the use of disease-free and genetically improved shrimp stocks represents a technological advance that many farmers consider necessary to remain profitable.

Threatening potential gains in efficiency is the continuing emergence of novel pathogens that create disease management headaches. Some examples are infectious myonecrosis (IMN) virus, and new variants of the taura syndrome virus (TSV).

Family-based breeding

Shrimp Improvement Systems, a United States-based shrimp-breeding company, has been developing multiple pathogen-resistant stocks of Litopenaeus vannamei that have also been selected for performance in highly intensive production systems. Its genetic improvement program employs a family-based breeding strategy that utilizes proprietary lines of specific pathogen-free shrimp.

Each year, approximately 250 full-pedigree families are produced at the company’s nucleus-breeding center in Florida, USA, and performance tested off site in controlled-environment disease challenges and field evaluations. The genetic improvement program selects for commercially desirable traits such as enhanced growth, resistance to specific pathogens like TSV and necrotizing hepatopancreatitis (NHP), and overall hardiness under high-density culture conditions.

TSV resistance

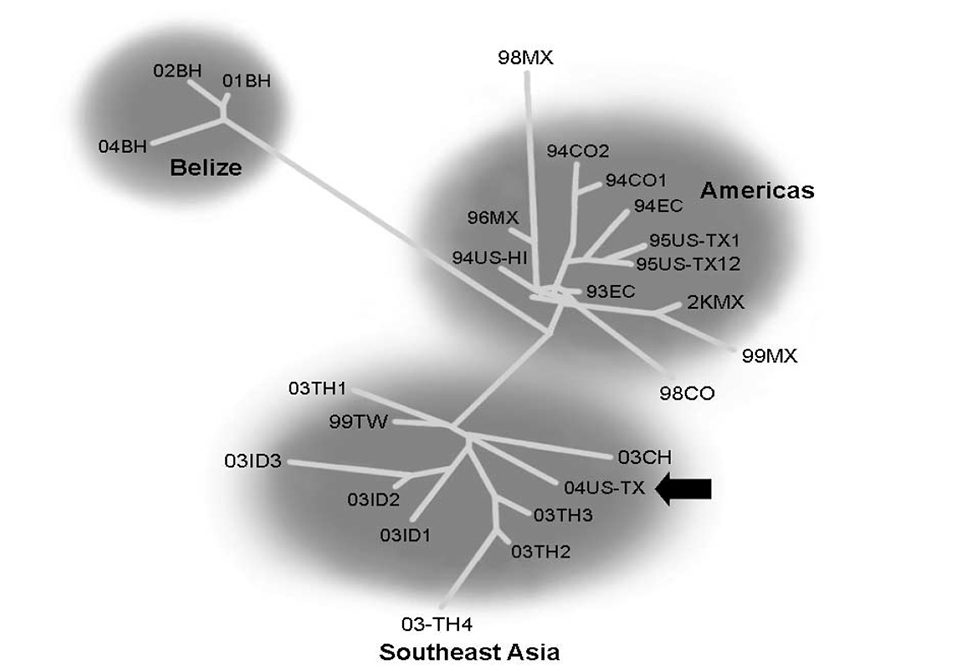

One of the challenges for genetic improvement programs focused on developing specific pathogen-resistant (SPR) shrimp is RNA viruses such as TSV, which can readily mutate and transform into serotypes that become virulent to previously resistant stocks of SPR shrimp. Many of the TSV strains in Fig. 1, which depicts the geographic distribution of serotypically different variants of the virus, have been associated with major disease outbreaks in different parts of the world.

In an effort to develop distinct lines of disease-resistant shrimp, Shrimp Improvement Systems conducted a large number of pathogen challenges of its selected SPR shrimp lines using TSV isolates collected from Belize, Thailand, and China. The results indicated that TSV-C, also known as Belize TSV, is the most virulent of all known variants.

Challenge testing

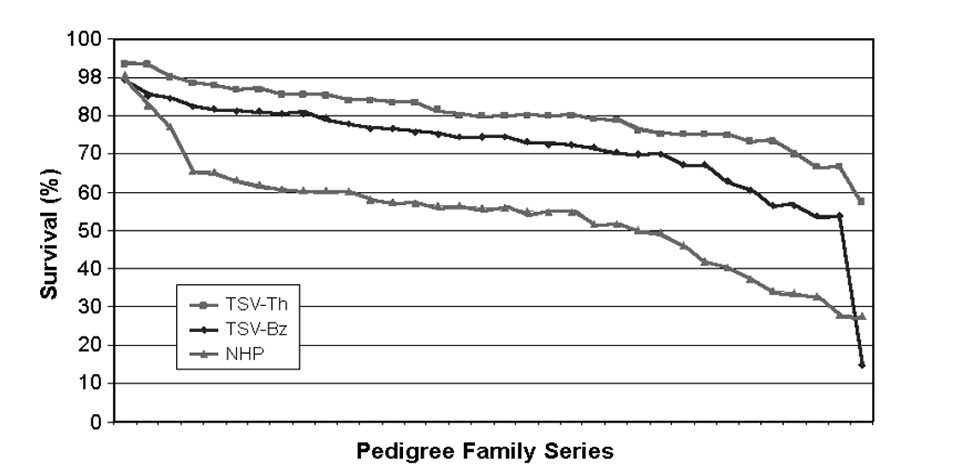

For example, beginning in 2003, SIS initiated same-family disease challenge comparisons of Belize TSV and Thai TSV. In controlled laboratory challenges with 40 pedigree families of its SPR shrimp, overall survival for all families fed Belize TSV and Thai TSV was 57 percent and 70 percent, respectively.

For comparison, another 40 families of SPR shrimp exposed to an isolate of TSV from China averaged 82 percent survival. These 40 families were the product of several years of selection for disease resistance using Belize TSV as the target pathogen. Several years of multi-pathogen disease challenges have demonstrated that lines of SPR shrimp resistant to Belize TSV were also equally or more resistant to other strains of TSV.

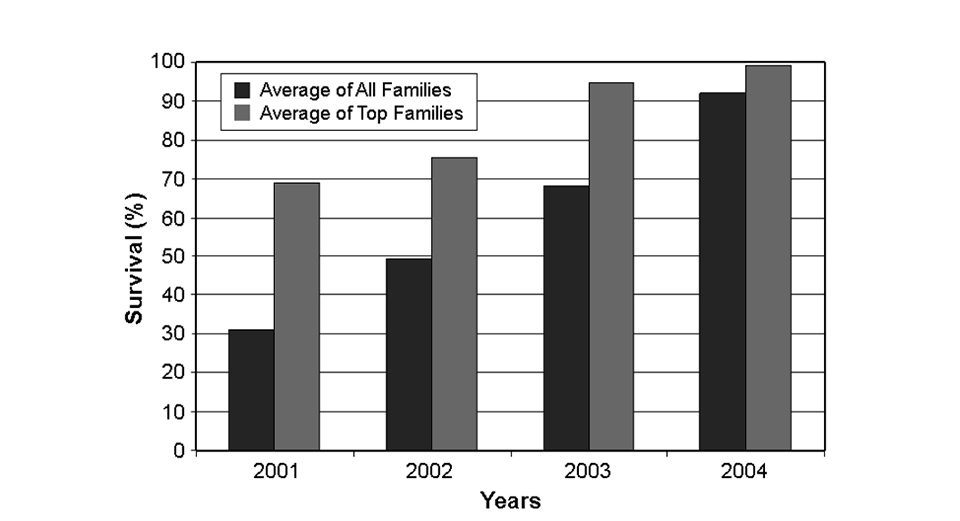

The top surviving families of each successive disease challenge are designated as progenitors for the next generation, and in this way, genetic gains on a family level are transferred through successive generations. The progress of selection for shrimp resistant to Belize TSV is depicted in Fig. 2.

Texas TSV

The most recent strain of TSV, 04US-TX (Fig. 1), abruptly appear-ed in mid-2004 in shrimp farms in south Texas, USA. This pathogen first appeared in ponds that were stocked with non-SPR shrimp selected only for growth. Based on its genotypic similarly with the Southeast Asian strains, the new strain of Texas TSV may have been inadvertently introduced into Texas from Southeast Asia via frozen commodity shrimp imported to packing plants in south Texas.

In a laboratory disease challenge conducted in 2004 by Dr. Ken Hasson at the Texas Veterinary Medical Diagnostic Laboratory, isolates of Texas TSV were fed to SPR shrimp and compared with non-SPR shrimp. The SPR stocks were almost 100 percent resistant to the Texas TSV, suggesting that it is much less virulent than TSV-Belize.

Multiple resistance

In countries where white spot syndrome virus (WSSV) is absent or nonvirulent due to ambient pond water temperatures consistently above 30 degrees-C, TSV and NHP are frequently the dominant diseases. Accordingly, Shrimp Improvement Systems started in 2003 to develop NHP resistance in its TSV-resistant lines to establish multiple pathogen-resistant (MPR) shrimp.

Fig. 3 depicts the results of a triplex disease challenge that exposed 40 MPR families to shrimp tissue containing either Belize TSV, Thai TSV, or NHP. The lower overall survival to NHP (54 percent) was likely due to the shorter selection history for NHP in these families, which until 2003 were strongly oriented toward developing resistance to TSV.

Selection for intensive culture

In an effort to increase pond yields to spread fixed costs over a larger product output, many semi-intensive producers are upgrading their ponds to intensive or super-intensive strategies with mechanical aeration and/or supplemental oxygenation systems. In addition, many of these high-density culture systems have adopted heterotrophic culture strategies with zero water exchange that further reduce production costs – particularly for L. vannamei – while minimizing the risk of introducing diseases from coastal waters supplies.

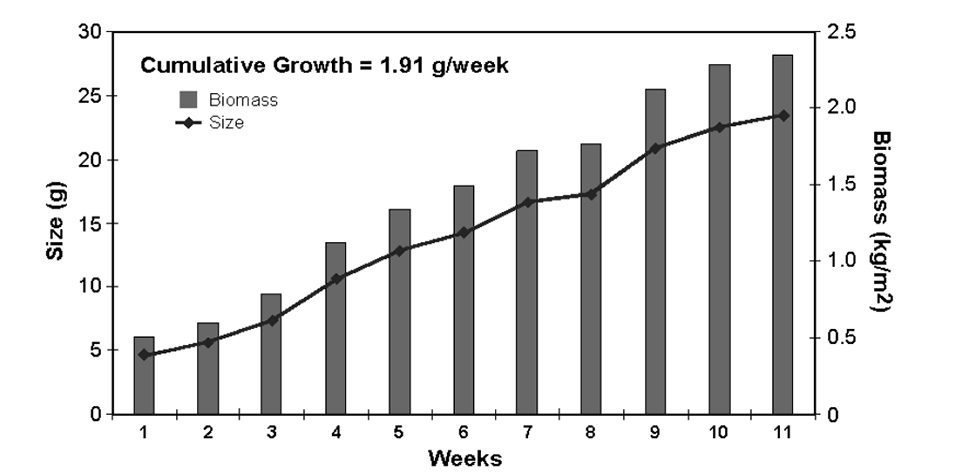

Recognizing this trend, Shrimp Improvement heightened its focus on selecting for shrimp stocks that readily grow in high-density, low-water-exchange culture systems. Fig. 4 presents growth data for selected stocks maintained in a prototype 400-metric-ton (MT) high-density culture system with supplemental oxygenation.

From 3-gramjuvenile shrimp, the animals grew to an average weight of 24 grams in 11 weeks at a final biomass of 2.4 kilogram per square meter. The shrimp have been successfully cultured to market sizes over 20 grams at biomasses of 5 kilogram per square meter in commercial ponds and up to 12.5 kilograms per cubic meter in prototype super-intensive tank culture.

(Editor’s Note: This article was originally published in the February 2005 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Henry C. Clifford

Shrimp Improvement Systems

88005 Overseas Highway, No. 10-166

Islamorada, Florida 33036 USA -

Edward D. Scura

Shrimp Improvement Systems

88005 Overseas Highway, No. 10-166

Islamorada, Florida 33036 USA

Tagged With

Related Posts

Health & Welfare

Black tiger domestication, selective breeding advance in Australia

Using clear-water tank systems, CSIRO and a collaborating farm have advanced the domestication of black tiger stocks in Australia.

Health & Welfare

10 paths to low productivity and profitability with tilapia in sub-Saharan Africa

Tilapia culture in sub-Saharan Africa suffers from low productivity and profitability. A comprehensive management approach is needed to address the root causes.

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Intelligence

Adding value to tilapia to tap into U.S. market

New markets for tilapia and expansion of existing ones can be created by planning and implementing properly designed geographic strategies to meet discriminating consumer preferences. Low labor costs in most producing countries promotes value-adding by the production of fresh fillets.