University of Gothenburg: Byproduct utilization can promote circular food production

A new study from the University of Gothenburg suggests that kelp flies (a type of insect) and marine yeast could be used as salmon feed. These two raw materials can be produced using byproducts from the seafood industry, which would otherwise be discarded.

“My research can help Sweden to achieve more circular food production, in which byproducts are reused instead of being discarded,” said Niklas Warwas, who wrote the thesis as a doctoral student. “This contributes to a more resource-efficient food industry, which is important when access to arable land and clean water is under threat and the population is growing.”

Currently, fish feed accounts for about half of the carbon footprint and production cost of farmed fish. Warwas’ thesis, Novel marine ingredients for aquaculture: Fish nutrition, physiology, and intestinal health, proposes kelp fly larvae and marine yeast as suitable alternatives to fishmeal and soybeans in fish feed. The fly larvae and marine yeast have over 50 percent high-quality proteins and high levels of beneficial omega-3 fatty acids that fish need to grow and thrive – ultimately, provide healthy food for humans.

“Both the fly larvae and the yeast have good nutritional values, and I noticed that the fish had a healthy appetite for the feed,” said Warwas. “Another important benefit is that such feed ingredients can strengthen the immune system and thereby protect the fish from diseases.”

Warwas’ findings highlighted opportunities for more circular food production that reduces environmental and climate impacts. The marine yeast was grown in a nutrient-rich brine byproduct from herring processing. Usually, this liquid is costly to treat before discharging it into the environment, but the water could be reused to produce a new raw material for fish feed. Similarly, kelp flies were fed on a residual product from algae cultivation.

Another advantage is that the marine yeast and fly larvae don’t need significant extra processing before being used as raw material in fish feed. This can cut down on the energy consumption needed to make the feed.

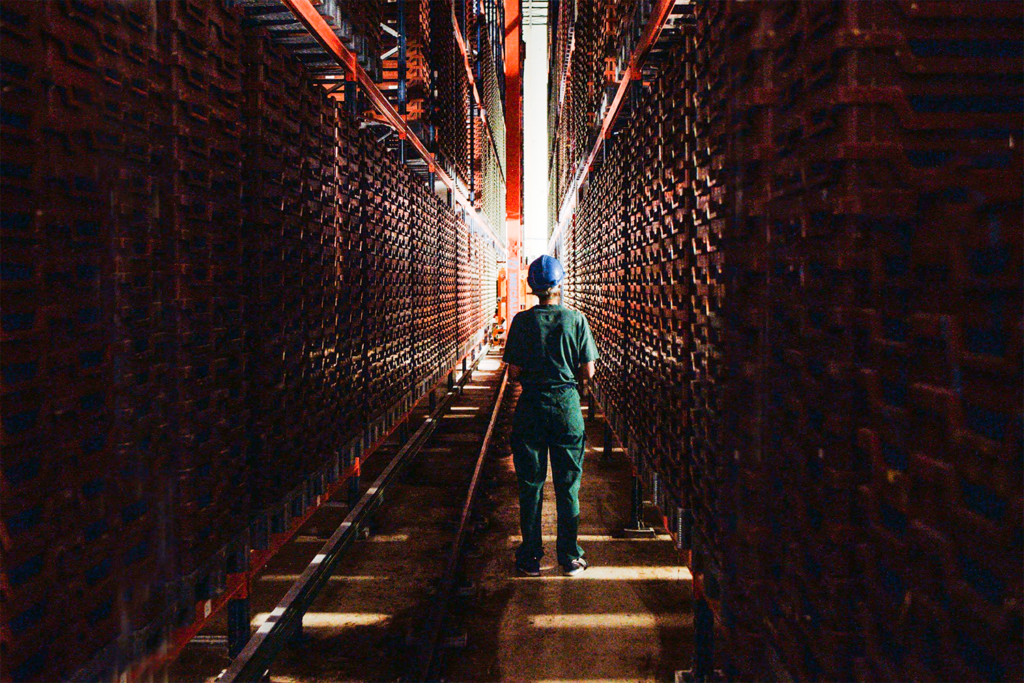

“Both the yeast and the insects can be cultivated on a wide range of different organic materials,” said Warwas. “It is important to create local circular systems where the fish feed can be produced close to the processing factories, which in turn can be located close to the fish farms. This reduces transportation requirements and makes these alternative feed ingredients more competitive.”

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

Tagged With

Related Posts

Aquafeeds

China approves the use of Calysta’s alternative protein in aquaculture feeds

Calysta has been approved by China’s Ministry of Agriculture and Rural Affairs to use its FeedKind® protein in fish and shrimp feeds.

Aquafeeds

Black soldier fly larvae meal cost-effectively replaces fishmeal in Pacific white shrimp postlarvae nursery diets

Black soldier fly larvae meal can effectively replace fishmeal in shrimp diets if nutrient balance and price sensitivity are properly considered.

Aquafeeds

Novel omega-3-rich canola oil approved for salmon feed use in Norway

Novel omega-3-rich canola oil makes fish healthier and minimizes dark melanin spots in salmon fillets, Nofima scientists say.

Aquafeeds

France has become innovation nation for insect production

With a thriving insect industry in France, new opportunities are emerging to advance aquaculture feeds and mitigate environmental challenges.