Viable Gear Founder Katie Weiler talks about lobster bait bags, kelp seeding lines and more with the Advocate and Aquademia

Katie Weiler made a personal pledge once to rid her personal consumption habits of plastics. She was so devoted to the cause that she developed an Instagram page with tips for others on how to follow suit.

“People would see me at the grocery store, trying to get people to wrap cheese in paper for me or bringing my own containers and stuff like that. And that’s really where I started diving super deep into plastics,” said the founder of Viable Gear, a Maine-based startup aiming to reduce petroleum-based plastics in the ocean by offering fishing and aquaculture equipment made with a polymer derived from seaweed. Weiler joined the Advocate and the Aquademia podcast this week. (Editor’s Note: Weiler’s podcast appearance and this article were published simultaneously.)

“Our first product to market that we’re targeting is going to be a bait bag for the lobster industry that can be used across industries. It’s a pretty important piece of gear that is used prevalently and can become ghost gear pretty easily in the ocean,” she added, referring to abandoned, lost or discarded fishing gear (ALDFG).

The big impediment to Viable Gear’s growth isn’t really up to the company. The seaweed farming industry, which has a lot of demands on it now for food and other products and stands to have even more in the future, needs to ramp up production to satisfy what could be robust demand for raw materials across different sectors.

“There’s so many benefits and we really just need to figure out how to scale it. That’s going to be the number one thing that we depend on,” she said, regarding U.S. seaweed production. “Everyone is going to need a lot of seaweed if a lot of these [seaweed product] companies take off. So that’s something we’re watching and I certainly don’t have the answers to it.”

One thing is clear, and that’s Weiler’s desire to source a product made entirely in Maine: “That’s the goal – to really create more demand for seaweed off the coast of Maine and hopefully it’ll be easier for our farmers to get their licenses.” The product itself is derived from the alginate found in species of brown macroalgae, like sugar kelp (Saccharina latissima) and others. Weiler credits Colin Hepburn at Everything Seaweed for helping to develop an alginate extraction process involving the use of centrifuges.

Viable Gear is still in its early research-and-development stages but may soon quicken its pace. Weiler said that the company – currently consisting of her and some advisors – is pursuing a grant to finance this growth and a pre-seed raise as a fallback. Hiring material scientists and polymer engineers would be the next step.

Despite the infancy of the company and the freshness of its prototypes, Viable Gear is attracting attention. Weiler presented to a room of international investors at the Blue Food Innovation Summit in London last month and has taken up office space at the New England Ocean Cluster in Portland, Maine, where she can rub elbows with innovative people across fisheries and aquaculture on a daily basis.

“The different companies that work there are fantastic and everyone is tied into either the blue economy or sustainability or the state of Maine,” said Weiler, who credits the Gulf of Maine Research Institute’s Gulf of Maine Ventures, the University of Maine, Bristol Seafood and others as helpful collaborators that she’s connected within her time there. “We’re also working with some kelp farmers to figure out a kelp-seeding twine that would be a little bit better for farming kelp as well.”

What’s been equally helpful in developing the lobster bait bag has been interacting with the fishers who will be using the product. She found the sternmen she connected with to be open and honest about how they use bait bags, how they fix them and what they’d be willing to pay for a plastic alternative.

“Right now, we can’t give an exact price, but we’re hoping it’s not any more than like 30 to 70 cents more than your typical bait bag,” which sells for about U.S. $2 each, she said.

Viable Gear’s lobster bait bag will be distributed by Brooks Trap Mill, which Weiler said is excited to have a “more sustainable payback out there” in the waters where lobster harvesters work.

“So anyone in the lobster industry, feel free to talk to me, even if you’re like, ‘This is ridiculous and stupid, it’s not gonna work.’ Any conversation is valuable. I would say it is gonna work and it’s gonna be great,” she said.

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

James Wright

Editorial Manager

Global Seafood Alliance

Portsmouth, NH, USA

Tagged With

Related Posts

Intelligence

‘We’re doing a lot of things that aren’t being done,’ says Los Angeles shrimp farm founder

Steve Sutton, CEO of TransparentSea Farm, joins the Advocate and Aquademia to talk shrimp and the carbon-capture technology investors should look at.

Fisheries

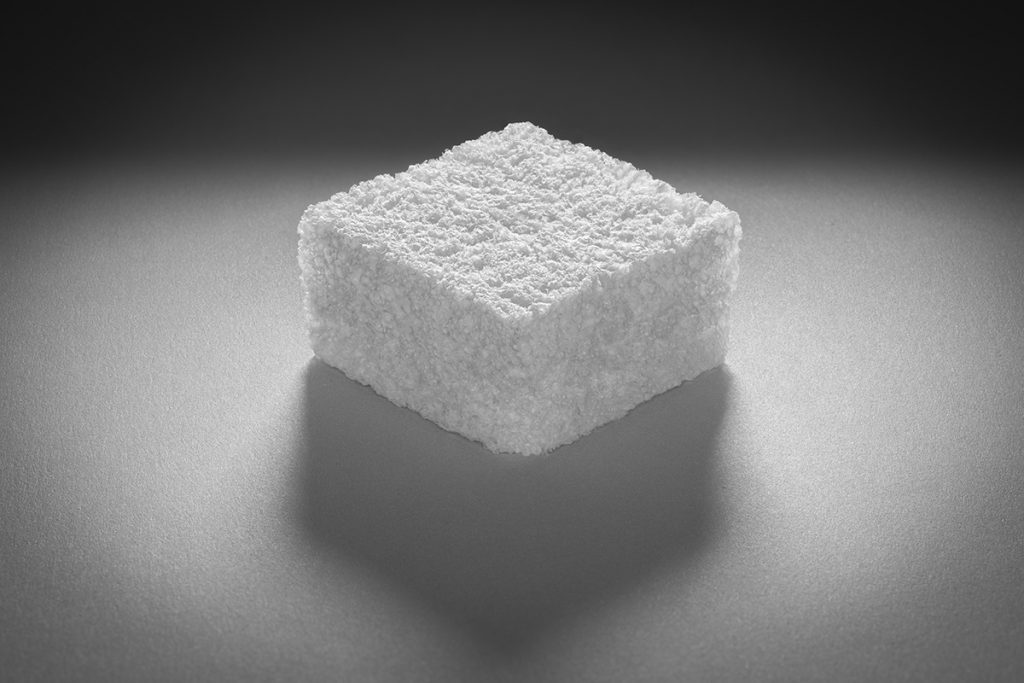

‘Regulation is pushing toward greenifying materials’: How one innovator is upcycling seafood waste into biodegradable packaging foam

GOAL 22: Cruz Foam’s biodegradable packaging foam made with shrimp shells is a finalist for GSA’s inaugural Global Fisheries Innovation Award.

Innovation & Investment

‘They know better than men how to protect their environment and people’: How focusing on women farmers is boosting food security in India

GOAL 22: The Government of Odisha and WorldFish collaborate to boost income and food security in India by teaching women’s groups to raise carp.

Aquafeeds

‘We will very likely find it’: Microplastics warning sounded for aquafeeds

The warning about microplastics pollution is finding its way to aquaculture, as a new study finds contaminated samples of fishmeal, a prominent aquafeeds ingredient.