Single-cell protein, already FDA approved, clears another major regulatory hurdle

The Canadian government has approved a single-cell protein from U.S. biotechnology company KnipBio for inclusion in farmed salmon feeds.

Thanks to the Canadian Food Inspection Agency (CFIA) ruling, farmers in one of the world’s largest salmon-producing nations can now include KnipBio Meal (KBM) in feeds for all salmonids.

“On June 8, 2022, the CFIA approved the Single Cell Protein meal derived from Methylorubrum extorquens for salmonid fish,” a spokesperson from CFIA told the Advocate. “This ingredient is approved for use in salmonid feeds as a source of protein, in an amount not to exceed 10 percent of the total diet. The company KnipBio Inc. obtained a CFIA registration for their source of this ingredient.”

KBM is already approved by the U.S. Food and Drug Administration, gaining GRAS (Generally Recognized As Safe) designation for finfish and shrimp feeds in 2019, becoming the first single-cell protein to do so. KBM is now approved in multiple markets for multiple species.

The CFIA approval process was complex, but the ruling will make conducting business across the North American aquaculture market “much easier,” company CEO Larry Feinberg said.

“CFIA designation is a clear indicator that a feed ingredient is effective and safe. This third approval is another important milestone for our company and moves us significantly ahead in producing healthier feed for healthier fish,” said Feinberg. “We are proud to be the first American company to invest in the scientific research necessary to receive this designation for aquafeed, and we are committed to building consumer confidence and trust in the safety and quality of our industry. We believe this CFIA approval, alongside FDA GRAS approvals, uniquely positions us to further penetrate the $50 billion global aquafeed market.”

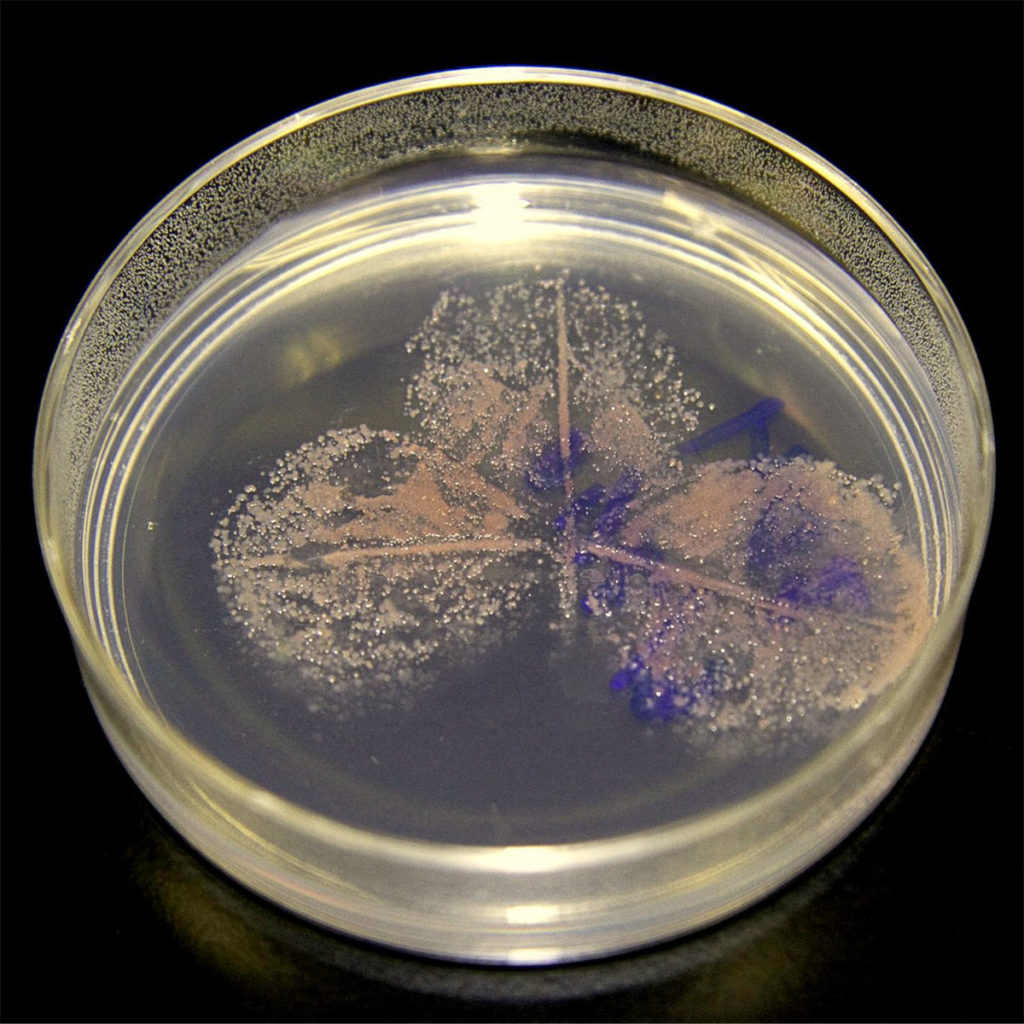

KBM is derived from the single-cell organism methylobacterium (Methylobacterium extorquens), a symbiont that grows on plant leaves. In KnipBio’s R&D lab and production facilities in Lowell, Mass., USA, the organism feeds on methanol, which is derived from low-cost and sustainable feedstocks, and then undergoes an industrial fermentation process in just a couple of days. The meal is the dried and processed form of the biomass.

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

Tagged With

Related Posts

Aquafeeds

KnipBio partners with ICM to scale-up production of single-cell protein for aquaculture

Leader in fermentation, bio-refining technology a “great strategic fit” for single-cell protein aquafeed ingredient maker transitioning from R&D labs to commercial production.

Aquafeeds

GOAL 2017 video: Larry Feinberg, KnipBio

In the second Pecha Kucha presentation from the Global Aquaculture Alliance's annual GOAL conference in Dublin, Ireland, Larry Feinberg of KnipBio talks about the potential of single-cell organisms as alternative aquafeed ingredients, and how his technology can lessen the industry's dependence on fishmeal and fish oil.

Innovation & Investment

Aquafeed opportunity attracts pioneers from fields afar

As business leaders switch focus from biofuels and energy to food security, one convert dubs the aquafeed opportunity a needed “redeployment” of knowledge.

Aquafeeds

A new nutrient for aquaculture, from microbes that consume carbon waste

Biotechnology firm NovoNutrients aims to produce a line of nutraceutical aquafeed additives as well as a bulk feed ingredient that can supplement fishmeal. Its process includes feeding carbon dioxide from industrial gas to a “microbial consortium” starring hydrogen-oxidizing bacteria.