Auburn University-led study examines the efficacy of low-cost salt mixture to replace reconstituted sea salt in inland, low-salinity farming of Pacific white shrimp

Culturing Pacific white shrimp (Litopenaeus vannamei) far from coastal areas – either in inland ponds filled with low-salinity well water (2 to 5 grams per liter), in indoor recirculating aquaculture systems (RAS), or in indoor biofloc systems (<15 g/L) – is a well-established and documented venture in different regions of the world. This is due, in part, to several advantages of inland over coastal shrimp culture, such as year-round production, increased biosecurity, diverse locations for shrimp farming close to various markets, reduced transportation costs, and the ability to provide fresh products to consumers.

Depending on the production system and strategy, reconstituted sea salts (RSS) are used for part or most of the phases to grow shrimp. In low salinity pond culture, RSS is often used for the nursery phase, because proper acclimation of postlarvae (PL) from full-strength seawater (≥ 30 g/L salinity) to low salinity is vital. In the absence of low salinity sources of culture water or full-strength seawater, indoor RAS and biofloc systems are often totally dependent upon RSS, as producers attempt to use water with ionic concentrations and ratios like that of seawater for optimum survival and growth of L. vannamei.

However, one of the primary challenges faced by U.S. inland shrimp farmers today is the high cost of RSS (Quagrainie, K. 2015. Profitability of Indoor Production of Pacific White Shrimp: Litopenaeus vannamei, a Case Study of the Indiana Industry, Purdue University Extension Fact Sheet), which can force indoor shrimp producers to reuse brackish water prepared with RSS for as many growing cycles as possible.

This article summarizes the results of various laboratory- and farm-based (in tanks) trials to test the efficacy of low-cost salt mixture (LCSM) to replace expensive, reconstituted sea salts in inland, low-salinity farming of L. vannamei.

Low-cost salt mixture

Though the importance of sodium (Na+), potassium (K+), calcium (Ca2+) and magnesium (Mg2+) to meet the physiological demands of cultured L. vannamei have been highlighted, the specific requirements for individual ions and ionic ratios are not well known and can vary depending on the ionic composition of the culture water.

Those circumstances continuously force inland shrimp farmers to use RSS, because ionic concentrations and ratios similar to seawater are the safest options for optimal survival and growth of L. vannamei. The concentrations of Na+, K+, Ca2+ and Mg2+ (mg/L) in 1 g/L diluted seawater are provided in Table 1. These concentrations can be easily converted to the required salinity by using the multiplication factor in Table 1 by the particular salinity used for production (Ex: Mg2+ concentration in 6 g/L salinity diluted seawater: 39.13*6 = 234.78 mg/L).

Galkanda-Arachchige, LCSM, Table 1

| Cation | Multiplication factor (mg/L) |

|---|

Cation | Multiplication factor (mg/L) |

|---|---|

| Na+ | 304.35 |

| K+ | 11.01 |

| Ca2+ | 11.59 |

| Mg2+ | 39.13 |

Revisiting ionic imbalance in low-salinity shrimp aquaculture

The low-cost salt mixture (LCSM) used in our trials was formulated based on Parmenter, et al. to yield Na+, K+, Ca2+ and Mg2+ concentrations closely comparable to that of diluted seawater using agriculture grade sodium chloride, magnesium chloride, magnesium sulfate, muriate of potash (potassium chloride), calcium chloride, and sodium bicarbonate (Table 2). Due to the variation of ionic concentrations at different salinities, farmers must adjust the salt compounds in their culture water based on the target salinity and water volume.

Galkanda-Arachchige, LCSM, Table 2

| Source | Purity* | Amount |

|---|

Source | Purity* | Amount |

|---|---|---|

| Sodium chloride-a | 99.9-95% as NaCl | 7.7 kg |

| Magnesium chloride-b | 47% MgCl2 | 1.0 kg |

| Magnesium sulfate-c | Mg=9.8%; S=12.9% | 1.2 kg |

| Muriate of potash (potassium chloride)-d | 62% K2O equivalence | 213.8 grams |

| Calcium chloride-e | 43% | 0.7 L |

| Sodium bicarbonate-f | 27.1% Na | 60.6 grams |

*-Based on the product details from the manufacturer/distributor.

a-Champion’s Choice, Cargill, Inc. Minneapolis, MN

b-Nedmag B.V., Veendam, Netherlands

c-Giles Chemical, Waynesville, NC

d-Mosaic Global Sales, LLC, Lithia, FL

e-Industrial Chemicals, Inc. Birmingham, AL

f-Church and Dwight co., Inc. Ewing, NJ

Results of the acclimation, nursery and growth trials

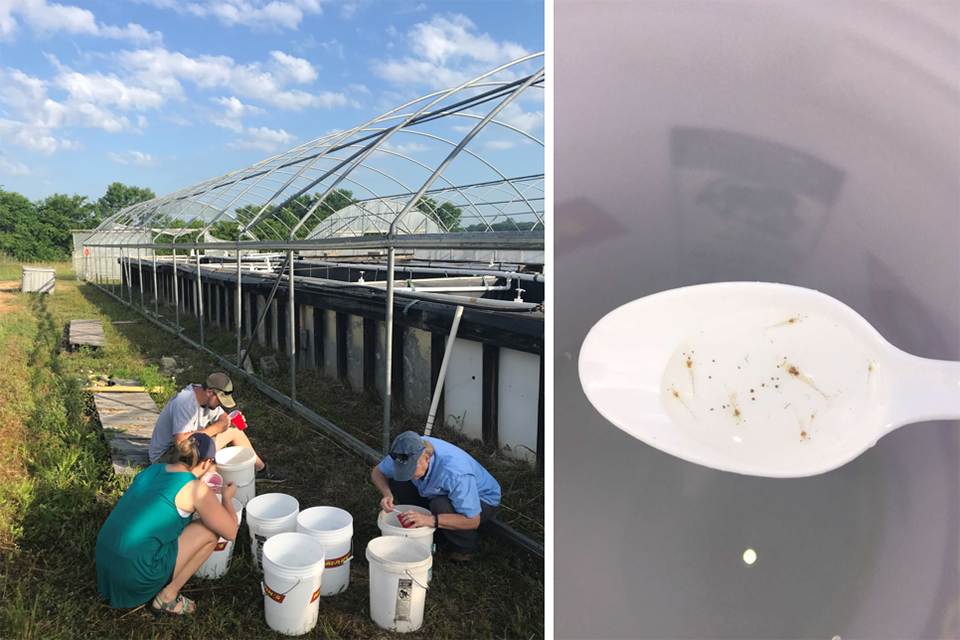

Numerous laboratory-based trials were conducted at the E.W. Shell Fisheries Center at Auburn University in Auburn (Alabama, USA) and at the Alabama Fish Farming Center (AFFC) in Greensboro (Alabama), at 3, 6 and 15 g/L salinities to test the efficacy of LCSM to rear L. vannamei. On-farm evaluation of LCSM along with salinity acclimation of PL was carried out in two tank-based systems installed on levees adjacent to shrimp production ponds at the Greene Prairie Aquafarm (GPA) in Alabama.

Acclimation water was prepared beforehand using amended pond water supplemented with RSS and LCSM in different combinations. Salinity acclimation was done from 32 g/L to 1.5 g/L salinity (PL size = 0.009 ± 0.02 grams) within three days by pumping (~3.5 L/min) low-salinity pond water (1.5 g/L) into each tank.

At the conclusion of the nursery trial, no significant differences were noted in either survival (89 to 94 percent) or growth of shrimp postlarvae between RSS and LCSM treatments, tracked for 21 days following salinity acclimation. These results were confirmed by the laboratory-based 21-day nursery trials, which also had no significant differences in either survival or growth of shrimp postlarvae between RSS and LCSM treatments at all salinities (2, 6 and 15 g/L) examined.

At the end of the 42-day growth trials, no differences were observed in survival, growth, osmoregulation, or concentrations of cations in the hemolymph of shrimp raised in RSS and LCSM treatments at the salinities (3, 6 and 15 g/L) examined. Results reflect the potential use of LCSM to replace RSS without compromising shrimp growth and survival in different production phases of inland low salinity shrimp aquaculture.

It is critical to highlight the need to adjust salt calculations considering the differences in purity and impurities of different commercial salt sources. Hence, Table 2 would only be accurate for this particular batch of ingredients available at the time to make the different salt mixtures. Therefore, it is always recommended to check the ionic concentrations of the medium before stocking shrimp. In addition, it is common to see differences in the solubility of different salt compounds due to variabilities in composition, availability of impurities, and other factors. Hence, it is advisable to thoroughly mix salt compounds with fresh water at least two days before use.

Perspectives

In conclusion, simplifying the mixed salt formulation rather than balancing all the different ions and trace minerals provided a savings of approximately 50 percent compared to the cost of RSS for commercial farmers. These results reflect the potential of LCSM to completely replace RSS, which could reduce overall production costs in indoor production systems, thereby stimulating the growth of the shrimp industry in the USA and other regions of the world.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Harsha S.C. Galkanda-Arachchige, Ph.D.

Corresponding author

School of Fisheries, Aquaculture, & Aquatic Sciences, Auburn University, Auburn, Alabama 36849 USA; and

Department of Aquaculture and Fisheries, Faculty of Livestock Fisheries and Nutrition, Wayamba University of Sri Lanka, Makandura, Gonawila 60170, Sri Lanka -

Luke A. Roy, Ph.D.

School of Fisheries, Aquaculture, & Aquatic Sciences, Auburn University,

Auburn, Alabama 36849 USA -

Anita M. Kelly, Ph.D.

School of Fisheries, Aquaculture, & Aquatic Sciences, Auburn University,

Auburn, Alabama 36849 USA -

D. Allen Davis, Ph.D.

School of Fisheries, Aquaculture, & Aquatic Sciences, Auburn University,

Auburn, Alabama 36849 USA

Tagged With

Related Posts

Aquafeeds

Alternatives to fishmeal perform well in low-salinity shrimp farm trial

In a white shrimp farm trial in a low-salinity environment, alternatives to fishmeal did not negatively impact the growth, survival or FCR of the shrimp.

Health & Welfare

Dietary modifications for desert shrimp farming

Since the first pioneer shrimp farm was established in the area in 1997, desert shrimp farming in Arizona, USA, has expanded rapidly.

Responsibility

Calcium and magnesium use in aquaculture

Aquatic plants and animals get the essential nutrients calcium and magnesium from water and food. Calcium concentrations impact the hydration and development of eggs in a hatchery, where calcium carbonate precipitation can be troublesome.

Intelligence

How India became the world’s top shrimp producer

Despite ongoing challenges, Indian shrimp farmers have achieved major developments in hatchery, farm grow-out and feed-manufacturing technologies.