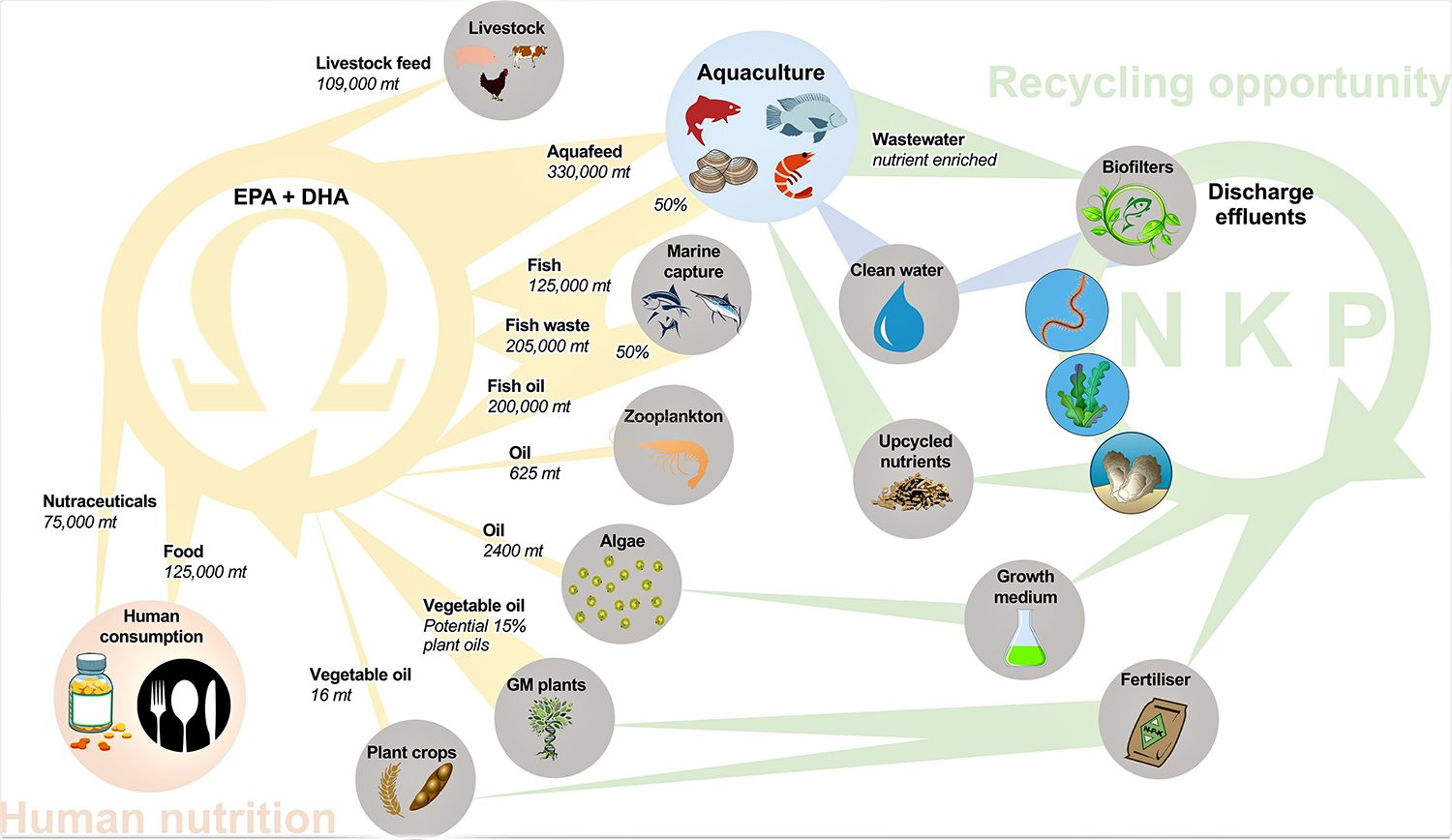

Key recycling opportunities in aquaculture and future challenges

Wastewater nutrients recycling (microalgal bioremediation, omega-3s, biofuel)

Aquaculture wastewaters are nutrient-enriched, with elevated concentrations of N, P, as well as trace elements K, Ca, Mg, Fe, Cu and Mn and could be incorporated into bacterial and algal biomass for high value. Many studies have demonstrated that liquid side streams are valuable reusable sources of nutrients for cost-effective cultivation of autotrophic, heterotrophic and mixotrophic cyanobacteria, microalgae and seaweed.

Raceway ponds have significant potential as a means for nutrient removal and biomass production. Raceways ponds can produce algal biomass at 10 to 25 grams per square meter per day from wastewater and have greater scalability and lower costs compared to tubular and flat panel photobioreactors (U.S. $2.95 vs $3.85 per liter algal oil extracted). In intensive land-based aquaculture systems, filamentous green tide algae have high bioremediation and upcycling potential, given their ability to retain 3.3 kg N per hectare per day and yield 1 to 1.5 kg of fresh weight per square meter.

Phycoremediation can also involve the use of immobilized cultures, for example in alginate or carrageenan, to facilitate the harvest of suspended microalgal cells. Revolving algal biofilm (RAB) systems can produce biomass more efficiently than raceway pond systems (15–30 grams per square meter per day) although initial investment costs are higher. Newly developed membrane photobioreactors (MPBR) allow the cultivation of microalgae at high concentrations which can remove 100 percent of NH3/day in dilute wastewater (<0.002 mg per liter) and produce up to 43 mg per liter per day of biomass. Electro-biochemical reactors (EBR) with microbial fuel or electrolysis cells can also produce energy or hydrogen while removing 74 percent of NO3- and 97 percent of TAN.

As algae are at the base of the food web, they also offer huge opportunities for nutrient upcycling in polycultures and multi-trophic aquaculture systems and to partly substitute commercial feeds (omega-3 oil). Omega-3 fatty acids could be accumulated in microalgae up to 10 to 60 percent of their dry weight, although this ability is species-specific. Genetic and metabolic engineering are being developed to increase the biosynthesis of omega-3 and silence genes for competing pathways. Concentrating omega-3 into a smaller volume of culture would allow a more feasible and cost-effective production intensification.

Besides its use for aquafeeds and CO2 sequestration, harvested microalgal biomass can have several other applications, such as being used as a natural fertilizer. With subsequent further processing, microalgae can contribute to added value components for nutraceuticals and pharmaceuticals markets and biofuel in biorefinery-based production systems. Metabolic engineering of microalgal pathways can optimize lipid production from these microorganisms and potentially maximize byproduct valorization. The sustainable production of microalgal biofuel at a large industrial scale is, however, still challenged by finding more economically viable methods of harvesting and lipid extraction. Energy requirements for producing microalgal biofuels are today still higher than the energy retrievable from the biofuel itself. Emerging techniques such as the hydrothermal liquefaction of wet biomass to crude oil or the supercritical fluid extraction and transesterification are showing significant promise with further optimization.

Upcycling nutrient systems (bioflocculation, IMTAs)

Bioflocculation technology (BFT) is an emerging and highly promising, cost-effective, environmentally friendly bioremediation option for land-based aquaculture systems. When wastewaters have a C/N ratio >10, BFT can reduce ammonium concentration ∼20 percent faster than nitrification and ∼30 percent more economically than conventional biofilters. Biofloc is of appropriate nutritional value for the cultivation of zooplankton, shrimp, red Nile tilapia and mussels and could reduce feed costs. In intensive shrimp pond cultures biofloc use has led to a net productivity 8 to 43 percent greater than conventional systems. And it has also been demonstrated that inoculation of bioflocs with specific microorganisms could act as a probiotic against pathogen loads in shrimp cultures and fish particularly at their early life stages.

Microalgal-biofloc sludges can be obtained through solid-liquid separation or air floatation and further upcycled through vermicomposting using polychaetes. Integrated polyculture systems have strong potential in valorizing added-value byproducts from farm effluents through nutrient upcycling and increasing of harvestable biomass. Several studies have shown positive effects of cultivating microalgae, oysters, mussels or seaweed in bioremediating polycultures, in wastewater effluents from fish and shrimp cultures.

Suspended particulates and phytoplankton can be cleared from the water by bivalves and other filter feeders in raceway side-stream settling basins to upcycle nutrients into yieldable biomass. Where large surface areas are available, seaweed biofiltration should be considered for upcycling nutrients. In integrated cultures with bivalves, complimentary biofiltration of seaweed can improve bioremediation efficiency and alleviate pressure from coastal eutrophication risk. In multitrophic systems, bivalve biodeposits can additionally be used as food for deposit feeders beneath cages, such as holothuroids, polychaetes and echinoids. These could bioturbate and oxygenate the sediments, and regenerate dissolved inorganic nitrogen, making it available for other extractive species, while potentially yielding 5 to 15 kg per square meter per production cycle in IMTAs. Deposit feeders, together with so-called extractive species, such as bivalves and seaweed, could be directly harvested for human consumption or used to feed other cultured species.

Integrated multi-trophic aquaculture (IMTA) may represent the most feasible bioremediation strategy for discharges from sea cages, ponds and extensive systems, allowing higher yieldable biomass and value-added co-products through economic diversification. Examples of these systems include the use of periphyton, constructed wetlands, aquaponics and integrated marine systems. In inland production systems, aquaponics can be a highly efficient mechanism for culturing both animals and plants with low water and energy requirements. Wastewater N and P removal by plants can be optimized by knowing the excretion and uptake rates of co-cultured species.

Key hurdles and future challenges

The reutilization of wastewater and aquaculture byproducts, coupled with improved feeding compositions and formulations, offers great potential to improve sustainability in the rapidly growing aquaculture industry. Some limitations, however, exist, and further research should address these challenges for the potential of sustainable aquaculture to be realized.

Feed production

Life Cycle Assessment (LCA) is a useful tool to provide production chain transparency and accountability. The production of raw material (especially fishmeal, soybeans and wheat grains) dominates the impacts categories, contributing from 18 percent to greenhouse gas emissions (i.e., global warming impact), to 88 percent of eutrophication impact. Improvements in feed formulation, manufacturing methods and in-farm management, while enhancing feed digestibility and thus reducing waste production, have reduced the food conversion ratios (ratio between biomass of feed and biomass of fish produced) from 3:1 to 1.3:1.

To address the issue of sourcing safe and more sustainable feed, significant effort and progress have also been made to suggest and test alternatives to fish meal and fish oil. This has resulted in a decreased Fish In: Fish Out (FIFO) ratio, a proxy metric to assess the impact of aquaculture on wild stocks. Further research advancement in the nutritional domain of aquafeeds is certainly a key element for achieving sustainability in the sector.

Resource reuse efficiency

For efficient reuse of side streams, wastewater treatment methods must be tailored to the daily loads, location and characteristics of a given aquaculture facility. The rates at which the effluents are discharged from different farms must be considered. Wastewater nutrient recycling into microalgal biomass is a promising sustainable route for limiting aquaculture waste and increasing production. The harvesting and extraction processes of microalgal biomass and lipids, however, still require technological advances to reduce operating costs and make resource reutilization environmentally sustainable.

Greater efficiencies are required in nutrient bioremediation and bioaccumulation in raceways, but metabolic engineering and strain selection could support optimization of lipid production. Thermochemical processing of microalgal sludge requires further improvements to make energy recycling within aquaculture economically feasible. Further investigations on bacteria-algal sludge co-digestion pathways are needed to improve sludge thickening processes and efficient recovery of byproducts at large scales.

Life-cycle assessments of aquaculture sludge byproducts, processed via different biological and chemical transformations, will add rigor to sustainable production prioritization and support the most sustainable by-product recovery path. Polycultures and IMTA offer effective means to upcycle nutrients through the food web in a cost-efficient manner. These types of farming, however, face various challenges. These include ensuring pathogen-free integrated systems, monitoring of nutrients and balanced co-culture of species, and requiring trained personnel to ensure scalability and food safety. Inclusion of probiotics in encapsulated diets could reduce antibiotics application and dispersal in the environment and improve product storage.

Byproduct processing and storage

Appropriate facilities for wastewater and seafood by-product processing, transportation, storage, and effluent management are critical. The processing of seafood byproducts needs to be carefully regulated in order to avoid microbial spoilage, preserve high nutritional value and ensure a fresh. Better control of oxidative stability and unfavorable odors dispersal, for example via fish oil refinement, would improve byproduct recovery.

Consumer acceptance

There is also a need to consider economic factors and consumer behavior. Aquafeed production costs will affect seafood prices, which consumers then use to inform their purchasing choices. For example, a survey involving more than 2,500 Europeans demonstrated that consumer choice was more closely linked to seafood quality, price and origin, rather than on production system. Ecolabelling and knowledge transfer toward consumers about environmental impacts and farming production practices would help reduce misplaced or incorrect environmental and health concerns amongst the public regarding aquaculture.

Perspectives

Without careful management of limited resources and wastewaters, aquaculture as an industry will fail to thrive under the increasing pressures of population growth and climatic change. Improved nutrient recycling practices, through technological advances in harvesting and processing wastewaters and byproducts, as well as optimization of feeding composition and formulations, can increase sustainable productive output to consumers and industry.

Recirculating aquaculture systems have the potential to intensify production and, given that the highly concentrated effluents are produced at lower rates compared to other farming systems, recycling capacity may be greater. Further research should move toward sustainable improvements of these systems, particularly focusing on efficient methods for energy circularity. Raceways and pond systems require improved designs to sustain intensified production. Flow-through systems with high rates of daily water load, and RAS systems with elevated energy demand, could utilize hydropower to reduce the carbon footprint.

Production in ponds and cages could be maximized through in-situ nutrient upcycling with polycultures and multi-trophic systems. With effective harvesting methods, nutrient recycling from wastewaters can allow upcycling of discarded material through the food web alongside cost-effective water bioremediation. Other lower-tech approaches can enable reduced costs for water treatment, feeds and antibiotics and maximize resource use efficiency. These include the use of probiotics, polyculture and multi-trophic systems.

All players in the value chain – including production, processing, transportation, storage and retail – have a role to play. For example, policymakers should facilitate different industries (e.g., aquaculture, agriculture, restoration, hospitality, tourism) to collaborate for more sustainable and resource-efficient cycles. Retailers need to innovate to increase public awareness of resource-efficient aquaculture practices and drive more responsible and sustainable seafood choices.

Long-term predictions on whether aquaculture will meet new global seafood demand are challenging. There is significant uncertainty in several key variables including climate change, marine ecosystem stability, international markets, and consumer and stakeholder preferences. Novel nutrient and byproduct recycling in aquaculture will, though, certainly play a key role in increasing production output. The circular economy can support aquaculture to grow and contribute to the sustainable nutrition of billions of people by 2050.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Camilla Campanati, Ph.D.

Corresponding author

Department of Zoology, University of Cambridge, Cambridge, UK -

David Willer, Ph.D.

Department of Zoology, University of Cambridge, Cambridge, UK

-

Jasmin Schubert, Ph.D.

RethinkResource, Hohlstrasse 400, Zurich, Switzerland

-

David C. Aldridge, Ph.D.

Department of Zoology, University of Cambridge, Cambridge, UK

Tagged With

Related Posts

Responsibility

Nutrient recycling and circular economies can support sustainable intensification of aquaculture, part 1

With nutrient recycling, aquaculture can contribute sustainably toward the nutritional requirements of billions of people over the next century.

Aquafeeds

Ecofeeds and the coming ecotechnology in aquaculture

Clearly, there will be no single solution to our needs, but rather a combination of biotechnological and ecotechnological solutions.

Aquafeeds

Microbial flocs spare protein in white shrimp diets

The authors conducted a study to determine how reducing the protein content of a diet would affect the growth performance of L. vannamei reared in an experimental microbial floc culture system.

Responsibility

Nutrient retention efficiencies in integrated multi-trophic aquaculture

First quantitative estimates for nutrient retention in IMTA systems show a large fraction of released nutrients retained by extractive species and harvested.