Commercialization will require improvements in spawning, feeding, broodstock domestication

Yellow perch (Perca flavescens) is being promoted as a candidate species for aquaculture in the United States. Yellow perch culture on a commercial scale is relatively new, however, and as such, its economic feasibility is largely unknown. Several marketing and biological constraints need to be addressed before yellow perch can be added reliably to the suite of species profitably cultured in the United States and elsewhere.

Yellow perch (Perca flavescens) is being promoted as a candidate species for aquaculture in the United States. Yellow perch culture on a commercial scale is relatively new, however, and as such, its economic feasibility is largely unknown. Several marketing and biological constraints need to be addressed before yellow perch can be added reliably to the suite of species profitably cultured in the United States and elsewhere.

Market

Yellow perch receives high marks for taste and texture. The species has been exceptionally popular around the Great Lakes region of the United States, and the collapse of the wild yellow perch fishery there has piqued interest in its commercial production.

Currently, the greatest market for yellow perch is within an 80-km radius of the Great Lakes. Considerable effort will be required to capture a wider market, although the existing market is barely being tapped.

Growth and market size

Yellow perch grow relatively slowly and reach sexual maturity at a small size (see below). The current market size for yellow perch is about 20 cm (115 to 150 grams), considerably smaller than most other commercially raised species. A minimum of nine yellow perch are required to produce a kilogram of fish in the round. Consequently, perch producers must bear a greater initial investment for fingerlings than producers of other species to reach that marketable kilogram in the same period of time.

Sexual maturity

In the wild, yellow perch males can mature sexually at age 1 at a size as small as 14 grams, while females mature at age 2 at a size of about 57 grams. Yellow perch in captivity have been shown to mature even earlier than wild fish.

They require a winter “chill period” with temperatures below 10 degrees-C to develop viable eggs. Yellow perch held above 10 degrees-C will not spawn, but the females still develop eggs that never fully mature. While the amount of energy diverted from growth to reproduction is less at higher temperatures, there is still a significant contribution of energy to the reproductive process – with a coinciding loss in dressout.

Protein requirement

The diet of yellow perch in the wild consists of zooplankton, insects, benthic organisms, and small fish. All of these food organisms exceed 50 percent crude protein on a dry-matter basis. Consequently, formulated yellow perch diets currently used in the industry are similar to, or the same as, those used for salmonids.

A study using practical diets demonstrated the nutritional requirement of yellow perch is closer to trout than to catfish, with the exception that lower dietary fat levels in conjunction with higher crude protein levels seem beneficial. Other studies using semipurified diets indicated that lower levels of protein might be possible, provided the dietary amino acid profile and carbohydrate content are appropriate for yellow perch. Fish nutritionists are in general agreement that more research is needed to develop commercial yellow perch diets.

Feeding and feed training

Studies of yellow perch diets in the wild indicate the piscivorous nature of these fish. Cannibalism can be expected under high-density conditions if the fish are not fully trained to accept a formulated feed. This adds to the cost of fingerlings, which currently is U.S. $0.07 to 0.10 for 2.5 to 7.6 cm fingerlings when purchased in large quantities, or $0.21 to 0.30 per 7.5-cm fish.

Since newly hatched yellow perch are quite small (4.7 to 6.6 mm), their mouth gape is not large enough to allow consumption of prepared diets. Due to the gape restriction, researchers and producers have largely been unsuccessful in training yellow perch larvae less than 18 mm in length to accept prepared diets. Consequently, fingerlings are stocked into predator-free fertilized ponds, where they consume natural zooplankton. Once fingerlings reach 18 to 20 mm, producers introduce feeds to initiate feed training.

Another common feed-training method is to place the fry in fertilized ponds, and transfer them to tanks when they reach about 38 mm. Approximately 70 to 90 percent of the fingerlings trained on feed using this method will convert to prepared diets. Although this approach generally results in substantial numbers of feed-trained fingerlings, the cost of producing them is increased because the technique is more labor-intensive and requires tanks in addition to pond facilities.

A third method used to feed-train fingerlings is to hatch eggs in tanks and then offer the fry rotifers, microalgae, and brine shrimp. Once fry are 35 days old, feed is offered. However, this practice is very labor-intensive, and requires a dedicated hatchery facility and personnel with the requisite experience.

Production systems

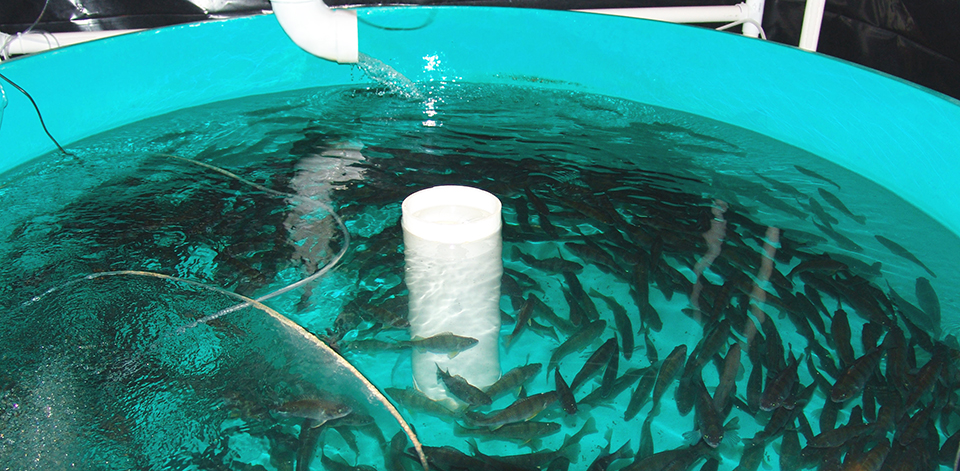

Yellow perch can be produced in ponds, cages, netpens, flow-through systems, and recirculating systems. Currently, pond production of yellow perch is the most economical approach and also results in greater harvests compared to flow-through and recirculating systems. Although higher numbers are often quoted, yellow perch producers now estimate pond production levels of 3,362 to 5,044 kilograms per hectare are possible.

Yellow perch can be raised in flow-through systems similar to those used for trout and salmon. It is estimated yellow perch can reach market size in nine to 11 months if they are cultured with a constant temperature and light regime. Yellow perch also can be raised to market size in recirculating systems. Although approximately 32 yellow perch farms using indoor recirculating systems emerged after 1970, most of them closed because the ventures proved economically unviable.

Yield and profitability

The dress-out percentage of yellow perch is estimated at 37 to 40 percent. Thus, a 150-gram yellow perch will yield 56 to 60 grams of edible flesh, provided the gonads are not fully developed. Gonads can account for 20 to 31 percent of the total weight in females and 8 to 15 percent in males.

Current wholesale prices for yellow perch in the round are reported to range U.S. $5.07 to 6.61 per kilogram. Fillets command considerably higher prices, because 20 or more fish are needed to obtain that yield.

A break-even price for an indoor recirculating system producing 22,727 kilogram per year has been calculated at U.S. $5.68 per kilogram. Considering that initial fingerling cost $1.89 to $3.62 per kilogram, very little margin is available for other variable costs (labor, feed, electricity, etc.) associated with raising this species to market size.

Conclusion

Profitable foodfish production of yellow perch is limited by their relatively slow growth rates, small sizes at maturity and high cost of feed-trained fingerlings. Current market prices, though relatively high, are not high enough for a reasonable return on investment. Extensive research is needed to improve feed-training techniques, delay spawning, determine nutritional requirements and domesticate broodstock before yellow perch can become a viable species for large-scale aquaculture production.

(Editor’s Note: This article was originally published in the October 2001 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Anita M. Kelly, Ph.D.

Department of Wildlife and Fisheries Mississippi State University

Mississippi State, Mississippi, USA -

Christopher C. Kohler, Ph.D.

Fisheries and Illinois Aquaculture Center

Southern Illinois University

Carbondale, Illinois, USA

Tagged With

Related Posts

Innovation & Investment

AquaBounty, with new RAS facility, hopes to win public support for GM salmon

Ron Stotish, CEO of AquaBounty Technologies, believes genetically modified salmon is no threat to its opponents and the outlook for AquAdvantage is good. With its purchase of the Bell Fish Co. RAS facility, commercialization will soon commence.

Aquafeeds

Buggin’ out: Tapping the potential of insect meal in aquaculture

Black soldier flies are gaining interest as a leading alternative ingredient in aquafeeds. But will the “ick” factor be a turn-off? Advocate contributor Clare Leschin-Hoar investigates.

Health & Welfare

Crowder/grader units improve harvest efficiency in large circular tanks

The use of larger and deeper tanks can reduce building, labor and other aquaculture production costs. However, the ability to grade and transfer large numbers of fish is more challenging when using large tanks. In a comparison of the effectiveness of a purse seine and a hinged clamshell to crowd fish in large tanks, the latter was easier to control and less stressful to salmonids. With a slotted bar rack in a side panel of the clamshell crowder, fish were simultaneously graded in size.

Health & Welfare

Live feed enrichment with probiotics

Probiotics can provide needed micronutrients that prime immune responses in larval fish, thus increasing their survival in culture. Probiotic dosing can be applied via immersion, microcosm approaches and enrichment of live and formulated feeds.