Startup Aquanzo is producing artemia in land-based facilities, with plans to scale

The global quest to feed farmed animals as sustainably as possible has thus far trained a laser focus on producing proteins like microalgae, insects and single-cell proteins. Ventures of varying sizes have experienced a range of results but the early-days outlook is promising.

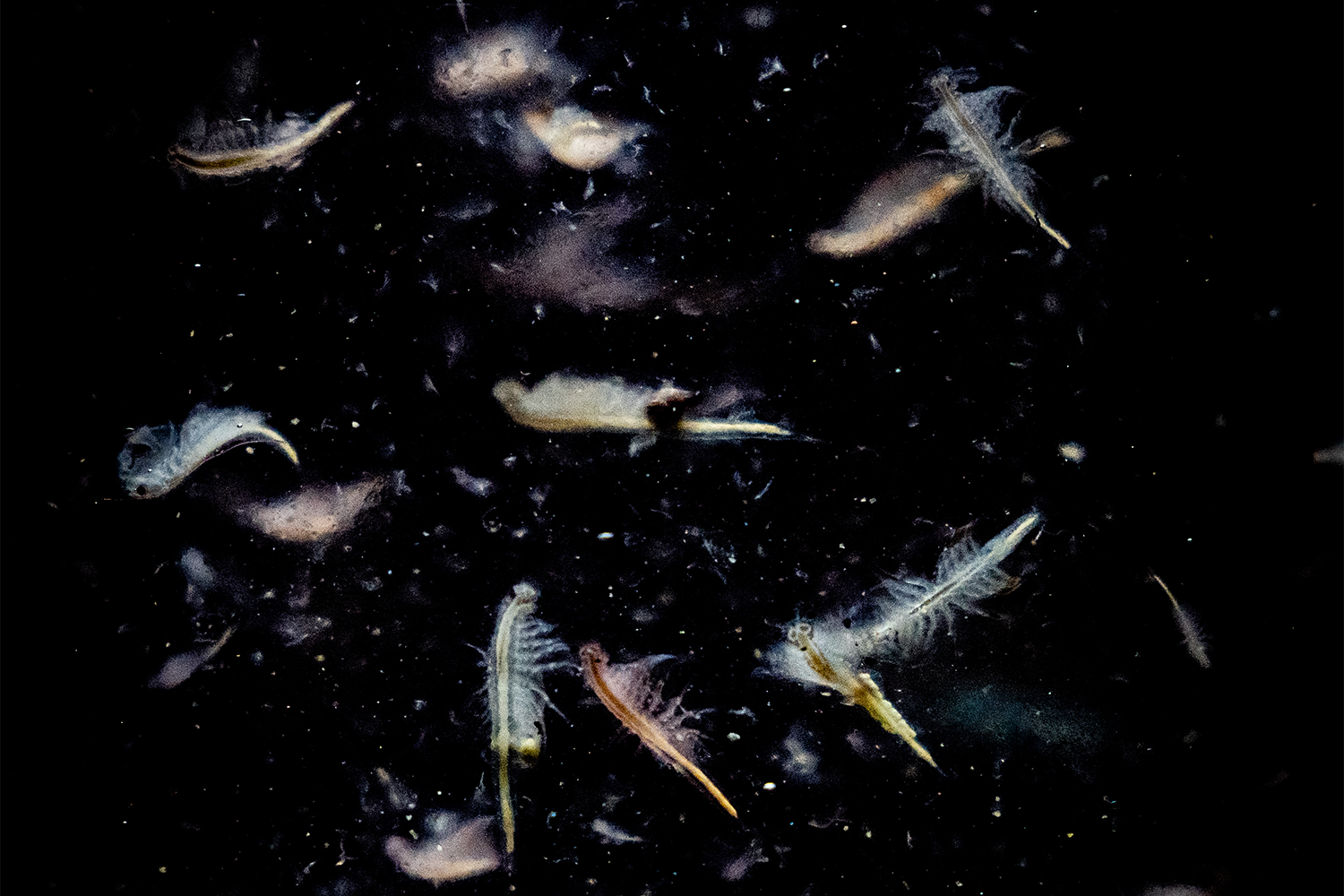

One company believes the solution to supporting aquaculture is to farm artemia – the microscopic brine shrimp that is the predominant live feed used in shrimp and fish hatcheries around the world – on land, using agricultural byproducts as feed and transforming artemia into high-value, protein-rich products.

“The current solutions to the marine protein crisis are alternatives like insects and single cell organisms, which are good, but they’re just alternatives,” Remi Gratacap, co-founder and CEO of Aquanzo, told the Advocate. “What if we could make more marine ingredients without harming the ocean? If we could farm marine ingredients, then we could scale them and be unrestricted by the wild carrying capacity.”

Based in Edinburgh, Scotland, Aquanzo was founded in February 2022, and though it’s still in its early startup stages, Gratacap has presented his research at numerous conferences, including the Blue Food Innovation Summit in London this past May.

Gratacap earned a Ph.D. in fish diseases and vaccines from Scotland’s University of Stirling, but opted to leave academia to join Deep Science Ventures in January 2021.

“I spent eight months understanding where the problems were in global aquaculture and realized that the biggest problem is that we’re simply running out of fish food like fishmeal and krill, which are fundamental for animal and aquaculture feed,” he said.

He partnered with Stephanie Lobnig, a process engineer with a background in the insect industry, and together they identified artemia as the perfect species for this transition. They created a recirculating aquaculture system (RAS) laboratory in Edinburgh’s Heriot Watt University that can produce artemia biomass, which is dried, ground into a powder and used to run in vivo testing in fish and chicken.

Artemia, the ‘magic powder’ fueling a multi-billion-dollar industry

“The RAS system we’re using is designed for large fish or shrimp, so there’s a lot of adaptation required,” Gratacap said. “Right now, it’s functional and working well, but I think we can make it work even better to improve productivity. And while it’s still too early to make any predictions, preliminary results on how farmed artemia affect fish performance are encouraging.”

Gratacap said Aquanzo has a strong advisory committee comprised of individuals with experience in animal feed, RAS technology and animal genetics. The company has raised £1.1 million (U.S. $ 1.4 million) in equity from venture capitalists and private investors. With its recent grant of £445,000 in funding to research the feasibility of farming artemia as an alternative marine protein for young chickens, it has a total of £1.5 million in funding.

If the laboratory tests produce positive results, the next step for Aquanzo will be to build a warehouse-size pilot facility. Gratacap and his team are still figuring out how large that would need to be.

“Since we’re the first ones to do this, we are frog lily-padding our steps up, but we are hopeful that Aquanzo’s work will have a significant impact on all aquaculture,” he said. “We’ll be the leading company, but there’ll be other artemia farmers the same way there are dozens of companies farming insects. And not everyone will do artemia because there are many other zooplankton that can be farmed. We just think artemia is the place to start.”

What if we could make more marine ingredients without harming the ocean? If we could farm marine ingredients, then we could scale them and be unrestricted by the wild carrying capacity.

Given the early stages of its research and testing, he said it’s hard to predict when an industrial artemia facility might become a reality.

“We think this is massively scalable, compared to the wild environment,” he said. “This would be a circular resource grown using 100 percent local agricultural byproducts. It would allow us to have very sustainable systems that use local, low-value carbohydrate products and transform them into high-value, protein-rich products. We’re basically transforming plant fibers into protein using artemia.”

Future facilities would need to be located close to feedstock producers and aquaculture users, to minimize the cost of transportation, a major cause of greenhouse gas in aquafeed. Gratacap said Aquanzo is looking at the northeast and west coasts of the United States, Asia and Australia as possible sites.

“We aren’t here to replace anything,” he said. “We don’t want to replace fishmeal if it’s sustainably harvested, because there’s no reason to. What we want to avoid is increased pressure on the ocean, and we believe we have a long-term, sustainable solution to do exactly that.”

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Lauren Kramer

Vancouver-based correspondent Lauren Kramer has written about the seafood industry for the past 15 years.

Tagged With

Related Posts

Innovation & Investment

Kenyan entrepreneur aims to set fish farmers up for success

Aquarech tackles challenges in feed, market access and financing for fish farming in Kenya, driving growth and profitability in the sector.

Intelligence

Maine seaweed farming company secures a kelp dryer and promptly decides to share it

Oceans Balance in Maine secured an industrial kelp dryer from South Africa that has the capacity to process other local seaweed farming producers’ plants.

Intelligence

‘No one knows what the risks are,’ say New England fishermen about pending offshore wind farm project

The New England fishing industry is worried that the approval process for a massive offshore wind farm off the coast of Rhode Island is moving too fast.

Responsibility

Brand new bag: Maine oyster farmers offer compostable bags made from beechwood

Ocean Farm Supply says compostable bags made from beechwood cellulose fiber are a more responsible alternative to plastics used for harvesting.