Global survey finds a high prevalence of MTS in skipjack tuna, significant business costs from rejections and downgrading and lower yields and productivity

Tunas are a major resource for potential economic development and food security for many island nations, contributing more than U.S. $40 billion to the global economy annually, with global catch steadily increasing. This increase is partially driven by the demand for canned tuna, as a simple and convenient seafood choice, especially in the United States and Europe. In 2018, canneries produced 4.1 million metric tons of tuna, with an end value of nearly $26 billion.

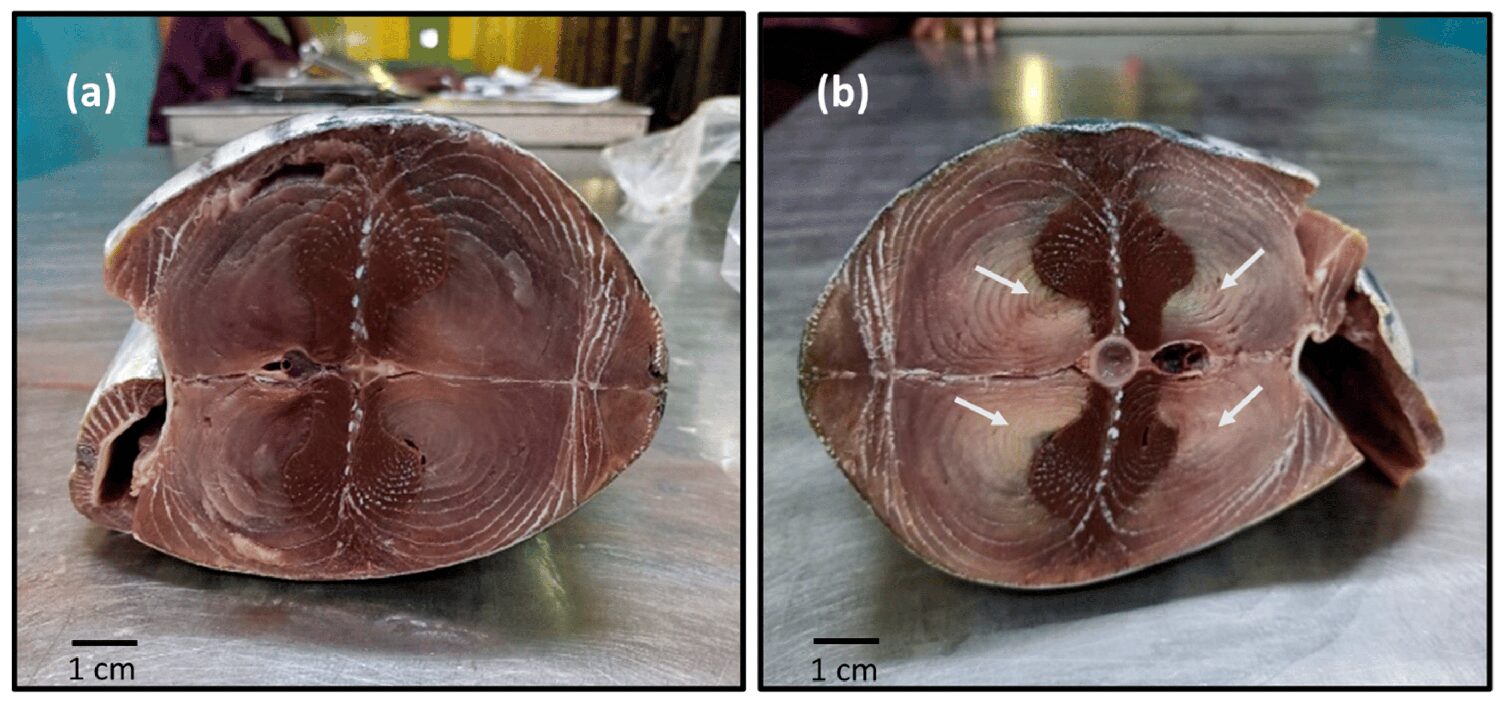

A considerable amount of tuna catch is lost due to various flesh quality issues. Mushy Tuna Syndrome (MTS) is one of the flesh quality issues affecting the tuna industry. MTS is a post-harvest textural quality defect in tuna wherein pronounced proteolytic softening of tuna meat is evident during processing, resulting in a canned product with an unacceptably mushy texture. While MTS may affect raw fish, it mostly causes a high number of rejections and the downgrading of processed fish for canning.

This article – summarized from the original publication (Peter, S.M.J. et al. 2023. Is Mushy Tuna Syndrome a Growing Problem for the Tuna Industry? Foods 2023, 12(19), 3590) – reports on the results of a survey to collect and analyze information from the industry to understand the scope of MTS, evaluate trends in its occurrence, and estimate its economic impact on the industry. Results highlight the findings from the tuna industry survey and form a knowledge base with which to inform further research on the drivers of MTS in skipjack tuna.

Study setup

We investigated the prevalence of Mushy Tuna Syndrome globally by surveying the tuna industry using a questionnaire. Given the global nature of the tuna industry, the survey was designed with a participatory approach to get respondents from different geographical locations.

The questionnaire was distributed by email to potential respondents through tuna industry stakeholders and government officers, and by directly contacting potential participants. The questionnaire collected profiling information from each respondent (scope of business, species handled, number of employees, tonnage per day, products, and main markets by country), followed by the incidence of MTS (occurrence of MTS, species, quantity and cost of rejects, trend, potential causes, consequences to business, and handling of rejected material). Respondents were also asked to provide data on fishing methods and fishing grounds, as well as their comments on the causes and impact of MTS.

Results and discussion

Among all of the commercially important tuna species, skipjack accounts for more than half of the total volume of tuna landed globally and are sold as canned tuna in nearly every region of the world, with 59 percent (n = 19) of the survey participants operating in Asia. Asia is the hub of the largest tuna processors, with Indonesia and the Philippines being among the top five tuna producers globally. Nearly 30 percent (n = 9) of survey participants were from Oceania, a region where tuna is an important source of protein and export revenue, with tuna processing and fishing providing up to 25 percent of the GDP in several Pacific Island Countries and Territories and the Western Central Pacific region contributing to nearly half of the world’s tuna fishery. This study confirmed that MTS is predominantly reported in skipjack tuna. The results from this industry survey complement earlier reports of MTS incidence and contribute to discussions regarding its implications for the tuna industry and its potential causes.

Skipjack tuna have a cosmopolitan distribution in tropical and warm-temperature waters. They are widespread throughout the Indo-West Pacific but are absent from the eastern Mediterranean Sea and Black Sea. The survey results revealed that MTS is prevalent across different geographical regions, indicating that it is not restricted to a particular area but distributed throughout the region where skipjacks are found. Thus, it was not surprising to find MTS cases in the different geographic locations where skipjack is processed – confirming that MTS occurrence is global.

We found that rejection rates and associated costs varied among participants, likely due to differences in the size of their operations and the volume of tuna they process. The cost of rejects reported ranged from less than $1,000 to over $1 million. Our data revealed that the median cost of rejection reported was more than $60,000 and that the average rejection rate was 1.8 percent. More than half of the respondents indicated an increasing trend in the occurrence of MTS, highlighting the need for further research into its causes. These findings highlight the significant financial impact of rejection rates on the industry. Participants in the Oceania region, which encompasses the Western Central Pacific Ocean (WCPO), reported particularly high costs related to MTS, as did Asia.

It is worth noting that the WCPO accounts for more than half of the world’s tuna fishery, and skipjack tuna production in the area has increased from 1.0 million tons to over 1.8 million tons in the last two decades. The revenue from tuna resources is vital as a source of income, employment, and food security for the region, and a food loss and waste scenario in the tuna value chain will have a substantial negative impact on the region.

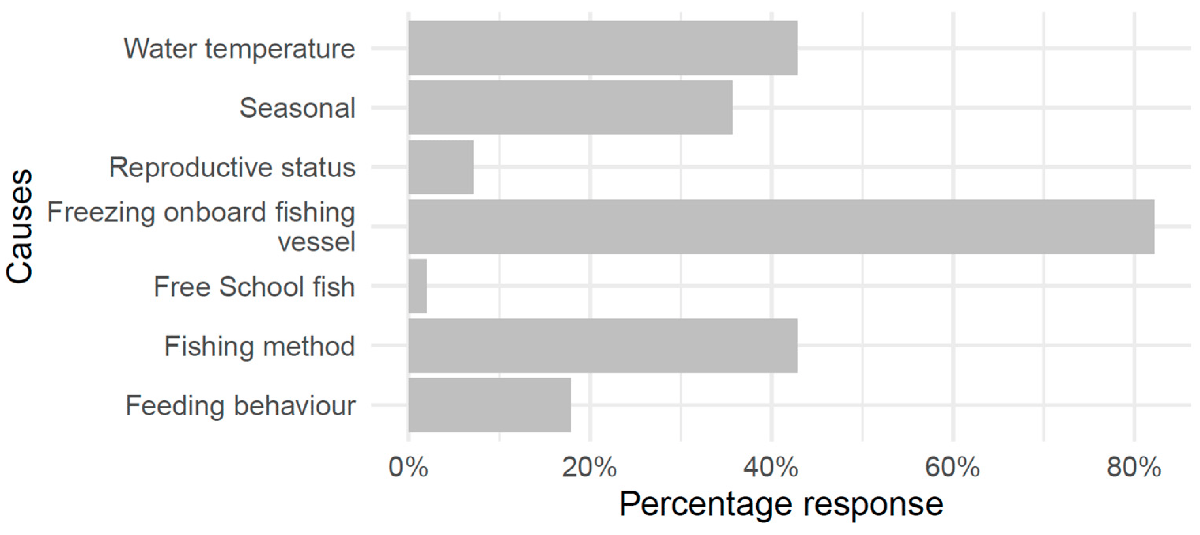

Concerning contributing factors of MTS incidence, numerous extrinsic and intrinsic factors can influence the overall quality of fish, such as species characteristics, seasonal biological changes in the gonads and muscles, fishing grounds and fishing techniques, post-mortem factors, and processing conditions.

For example, research into albacore tuna has shown that high body temperature when landed (26–30 degrees-C) increases the initial rate of chemical reactions and enzymatic activity, contributing to decreased flesh quality before it is refrigerated. Also, the more slowly the fish is frozen, the larger the ice crystals become, and large ice crystals damage the ultrastructure and concentrate the solutes in the meat, leading to alteration in biochemical reactions at the cellular level, providing greater potential for texture loss. Temperature control during the various stages of thawing, handling, and thermal processing before precooking is therefore crucial in maintaining the texture quality of the canned tuna product.

MTS is not consistently seen throughout the year, so there may be other factors that could trigger MTS prior to harvesting and freezing. Seasonal trends in the occurrence of MTS raise the question of the effect of environmental and biological conditions on the texture of the muscle post-harvest and post-cooking. For most participants, the incidence of MTS was not the same in all years. Some authors have noted the coincidence of MTS with the El Niño event, when there is a rise in surface water temperature in the Central and Eastern Pacific Ocean, suggesting a role of temperature and changing oceanic conditions in MTS.

Based on the findings of our survey, there are several potential contributors to MTS (fishing method, onboard freezing, seasonal, free school fish, reproductive status, feeding behavior, and sea surface temperature) that should be further examined, and are discussed in the original publication.

Regarding the consequence of mushy tuna syndrome incidence to business, for the canning industry, which is the main pathway to consumers for most of the world’s tuna catch, texture is one of the most important quality factors, and is driven by consumer expectations of a high-quality product. Achieving a higher yield—meaning more canned product per ton of processed tuna—is a top priority, while also ensuring good quality canned meat. The survey results show that lower yield and lower productivity were followed by customer complaints as the main consequences of MTS, which affects the textural quality of tuna meat. Processed meat that is no longer suitable for processing is downgraded to fishmeal production and more fish need to be caught and processed to meet market demands. A total of 46 percent of the respondents noted stressed workers as one of the consequences, due to the drive to meet customer expectations of high-quality tuna product. Overall, it is evident that MTS is of consequence to businesses that process skipjack tuna.

Perspectives

This is the first attempt to quantify the prevalence and severity of Mushy Tuna Syndrome globally. We found both a high prevalence (97 percent of the respondents noting that they have had MTS in their skipjack tuna) and business costs ranging from less than $1,000 to over $1 million around the world due to rejections and downgrading, lower yield, low productivity, and customer complaints. The higher levels of rejection could affect sustainability, as the industry needs more of the catch to process fish for the same contracted volumes of the final product.

The environmental conditions, such as sea surface temperature, reproductive stage, the behavior of fish while feeding, and the potential impact of the harvesting techniques and subsequent freezing methods, which could lead to stressful muscular activity following capture and eventually affects the pH of the fish, are all potential extrinsic and intrinsic factors that could cause MTS. Further research is needed to understand the biochemical basis of MTS and understand the integration of disparate areas of study to forecast – based on the environmental and fish body conditions, harvest, and handling methods – the occurrence of MTS, particularly under climate change conditions.

An increased understanding of the contribution of these factors will be vital to the development of forecast tools that will benefit the fishers and processors by allowing them to adjust harvest strategies, fishing practices, and processing practices, through the identification of conditions that are likely to be associated with MTS. A cost-effective, rapid, non-invasive technique to identify fish that have a high probability of displaying MTS would also be useful, as it would enable processors to divert such fish to an appropriate product line. This would reduce fish waste and increase economic efficiency and fishery sustainability.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Prof. Louwrens Christiaan Hoffman

Corresponding author

Centre for Nutrition and Food Sciences, Queensland Alliance for Agriculture and Food Innovation (QAAFI), The University of Queensland, Brisbane 4072, Australia; and Department of Animal Sciences, University of Stellenbosch, Stellenbosch 7600, South Africa

Tagged With

Related Posts

Fisheries

A synthetic control approach to estimate the effect of total allowable catch limits in the high seas

Research highlights the potential of a synthetic-control method to estimate the causal effect of catch quotas on fishing mortality and biomass.

Fisheries

Fisheries in Focus: Marine protected areas don’t help tuna population, new paper shows

Using stock assessment and fishing data, researchers find that the Phoenix Islands Protected Area did not meaningfully increase the tuna population.

Fisheries

How aging uncertainty of major tuna species impacts the estimation of growth functions

Aging error and age range influences the uncertainty of growth estimation in major tuna species, necessitating improved accuracy of age analysis.

Fisheries

Fisheries in Focus: What are fish aggregating devices and why is there debate about banning them?

Use of fish aggregating devices increases fishing efficiency but can potentially increase bycatch and ocean pollution if FADs are lost or abandoned.