Target moisture levels can help prevent abuses of either nonphosphate blends or phosphates

Water is the largest and most influential part of all edible shrimp products. It contains the significant nutritional components and flavors, and provides the moisture associated with product taste, texture, appearance, and yield. The right amount of moisture results in preferred shrimp, while low or excessive moisture content can result in objectionable or inferior-quality products. Low moisture is associated with dry and overcooked shrimp. Excessive moisture can cause a slippery texture or glassy appearance.

Phosphate use

Mindful of these concerns, research and commercial practices have stepped forward to control, restore, and protect moisture during harvest, processing, distribution, storage, and preparation. Since the 1960s, phosphates have been the additive of choice for maintaining proper moisture levels in processed shrimp.

The idea for phosphate addition was based on the influence of the natural phosphates commonly found in all edible muscle foods. Natural phosphates such as adenosine triphosphate are involved in muscle activity and water binding for structure and function. Similarly, various phosphating agents can be added to edible shrimp muscle to restore natural water-binding capacity.

This preservative role has been recognized by the United States Food and Drug Administration and other national authorities, which designate the phosphates as generally recognized as safe (GRAS) ingredients for use in accordance with good manufacturing practices.

Moisture control

Successful programs for the control of moisture in shrimp depend on the proper concentrations of phosphates for the best product performance and consumer preference. Exposure time and the related product temperatures are key factors in developing a process that provides product protection without compromising product taste, texture, or appearance.

Ideally, buyers or processors should conduct studies with actual products and processing operations that include the opinions of the most important people in the value chain, consumers. The results will determine the best treatment specifications for their particular shrimp products.

Many shrimp operations are ahead of the game, with outstanding treatment specifications already in practice. Some, however, stretch the use of additives as far as possible. These operations have divided the U.S. market into prophosphate buyers and antiphosphate buyers.

Antiphosphate buyers

The antiphosphate buyers include firms looking for products with no additives, commonly known in today’s market as “chem-free” shrimp. This approach assumes any use of additives is bad and there are no reliable processors.

Although certain situations can encourage such an approach, the results do not always guarantee trouble-free shrimp. Over 15 years of research, processing studies and market experience have shown that properly phosphated products can be preferred. Chem-free products could be another form of deception.

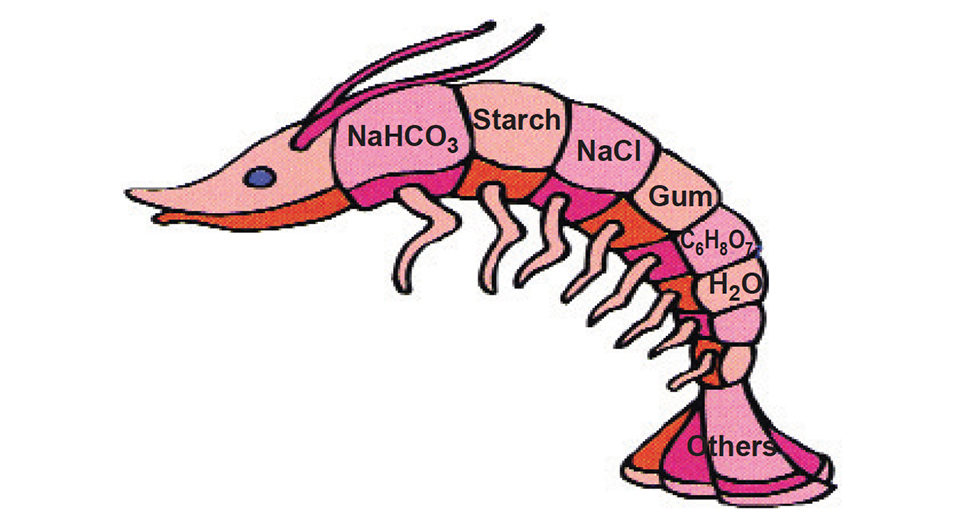

Does chem-free mean no use of phosphates or no use of additives? The chem-free buyers intend to specify no phosphates, but may not inform suppliers that they are not interested in any other additives. This practice could actually encourage the use of nonphosphate blends, which may include salt, bicarbonates, citrates, gums, starches, milk proteins and other ingredients.

Nonphosphate blends

Many of the ingredients used in nonphosphate blends are additives with recognized GRAS status, but their intended effects are not moisture control or protection. The blends contain two or more ingredients mixed to mimic the function of phosphates. In some cases, the ingredients may not be food-grade substances, which are illegal for use with shrimp in food-processing operations. Such blends are seldom sold by the established producers of food-grade additives. The majority of the nonphosphate treatments are provided by local blenders.

In all cases, buyers must be informed about all ingredients used in shrimp. This information is necessary to judge product performance in storage, thawing, and cooking. It is also needed to determine the required labeling information that must be included in ingredient statements on packaging.

Although nonphosphate blends can appear effective in boosting processing yields, they may lack performance in maintaining product moisture in frozen storage and when the product is thawed and cooked. These blends do not have the water-binging capacity possible with appropriate phosphates. In fact, using these questionable blends – primarily as a water addition practice with limited retention – defies the purpose of controlling moisture in finished products.

Other potential problems include:

- Off-flavors due to excessive sodium bicarbonate. Attempts to mask the off-flavors with sodium chloride only increase the sodium levels in the finished products.

- Release of carbon dioxide when value-added products are exposed to vinegar, lemon juice, and other acids used in marinades. The extra gas can influence packaging appearance and integrity.

- Foaming when the shrimp are cooked at home, along with the appearance of a white protein weepage or curd on the surface of the cooked shrimp.

- Potential for allergic reactions to some components such as milk proteins.

Target moisture level

Buyers have a legal and moral responsibility to provide consumers with safe, top-quality shrimp. Product specifications that clearly identify acceptable phosphate types, concentrations, exposure times and treatment temperatures are a proven approach for consistent and preferred quality. On the other hand, buyers who clearly do not want any applications of phosphates or similar additives should specify they want no additives, including nonphosphate blends.

In either case, buyers are encouraged to specify acceptable moisture ranges for finished products when thawed and/or cooked. Target moisture levels can help prevent abuses of either nonphosphate blends or phosphates.

Keep in mind that the ideal moisture target range involves both product performance and buyer and consumer preferences. Once these factors are known, monitoring for moisture content is easy and economical.

(Editor’s Note: This article was originally published in the August 2005 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Laura R. Garrido, M.S.

Aquatic Food Products Lab

University of Florida

P.O. Box 110375

Gainesville, Florida 32611-0375 USA -

Steve Otwell, Ph.D.

Aquatic Food Products Lab

University of Florida

P.O. Box 110375

Gainesville, Florida 32611-0375 USA

Tagged With

Related Posts

Health & Welfare

Chem-free fixes emerging in sea lice saga

Salmon farmers, using emerging technologies, are exploring new methods of sea lice mitigation in an effort to overcome one of the industry’s most persistent problems. New chemical-free innovations show an industry eager to adapt and adopt environmentally safe practices.

Innovation & Investment

Thinking outside the cage: Avant-garde aquaculture in Norway

Salmon farming in Norway is poised for an innovation boom. The biggest players are putting cutting technology in the water to solve some of the industry’s most persistent problems, such as sea lice, fish escape and waste management.

Responsibility

Warming oceans prompt adaptation efforts for aquaculture

A five-year study in Canada aims to provide more answers about warmer waters with lower oxygen levels and a way for farmed fish producers to adapt to climate change.

Aquafeeds

A look at phospholipids in aquafeeds

Phospholipids are the major constituents of cell membranes and are vital to the normal function of every cell and organ. The inclusion of phospholipids in aquafeeds ensures increased growth, better survival and stress resistance, and prevention of skeletal deformities of larval and juvenile stages of fish and shellfish species.