Study identifies many marine organisms nutritionally suitable as aquafeed ingredients

Currently, much of the global aquaculture production is for fed organisms that rely heavily on formulated feed. Thus, the increase in aquaculture production has a generally linear relationship with the increase in feed production. The inclusion of fishmeal and fish oil, a common source of protein and lipids in aquafeeds in decades, has substantially declined and most raw materials in aquafeeds are now agricultural products produced in terrestrial systems.

The marine ecosystem offers vast opportunities for the production of produce seafood products and aquafeed raw materials. The intense competition for raw materials due to other human uses, which affects aquafeed supply, is a major motivation for the aquaculture sector to generate its own feed raw materials from marine sources.

The demand for high-quality materials for various human-related applications has been increasing, creating more opportunities for the aquaculture sector to produce marine-based, high-quality raw materials for various human needs, including other food-producing sectors such as livestock production. Aquafeed raw material exploration should focus on unfed marine organisms, which can act as bioremediators that extract waste nutrients from the environment and convert them into beneficial biomass that may be used as feed raw materials.

This article – adapted and summarized from the original publication (Jusadi, J. et al. 2021. Potential of Underutilized Marine Organisms for Aquaculture Feeds. Front. Mar. Sci., 11 February 2021) – discusses the potential use of some underutilized marine organisms as candidates for ingredients in aquafeeds, with specific emphasis given to unfed low-trophic-level organisms such as shellfish, seaweed, and microorganisms.

Selection criteria for aquafeed raw materials

The following criteria should be considered when selecting appropriate aquafeed raw material: (1) nutritional value relative to the requirement of the cultured animal and its digestibility by the target animal; (2) the presence of antinutritional factors (ANFs) and contaminants; (3) supply reliability; and (4) price volatility. The nutritional composition and digestibility of feed materials have synergistic effects on growth outcomes of fed aquaculture species. In addition, the physical and nutritional qualities of raw materials should also include their characteristics during manufacturing processes and how they affect the pellet quality.

High digestibility ensures high nutrient bioavailability and utilization by the animal. The presence of antinutritional factors, i.e., substances that could interfere with food utilization and negatively affect the health and production of animals, is an important factor determining the nutritional feasibility of a raw material for aquafeed. In addition, marine-origin raw material may carry the risk of contamination by heavy metals and toxins, with potential direct or indirect adverse effects on the fed organisms and final consumers.

In the aquafeed industry, the use of materials with routine and consistent supply is critical to reduce the risks of fluctuations in product quality and specification, cross-contamination, and shortfalls in supply during manufacturing. Thus, continuous supply of a particular raw material in bulk quantities should be one of the major considerations when selecting potential raw material for aquafeed.

The price volatility of a raw material, which is strongly influenced by its supply and demand, is the main economic factor affecting profitability in aquafeed manufacturing. In the context of raw material production, the supply of a raw material in bulk at an affordable price implies that the culture productivity, i.e., production per unit of area or per unit of water, and the processing cost of the marine-origin raw material should be comparable to that for the production of existing terrestrial-based raw materials. How new raw materials influence the environmental and social sustainability of aquafeeds are also critical considerations in the development of new feed products.

Some animal sources

Feed raw materials of marine animal origin are mostly used as sources of essential amino acids and essential fatty acids for most aquacultured animals. There are at least three animal-origin materials that have the potential to be used as a protein source in aquafeeds: mussels, artemia and amphipods. These animals are low-trophic-level organisms that extract nutrients from primary producers such as microalgae and/or particulate organic matters in the aquatic environment.

Mussels such as green and blue mussels are extractive organisms that grow rapidly in nutrient-rich environments and act as bioremediator agents converting waste nutrients into protein. Mussels contain considerably high protein [50 to 70 percent dry weight (DW)] and lipid (5 to 16 percent DW) levels, with comparable essential amino and fatty acids contents to those of fishmeal. Several studies have demonstrated that mussels are a promising protein source in aquafeed, with a reported maximum inclusion level of up to 25 percent. From an ecological perspective, mussels have been considered to play some important roles in carbon fixation and mitigation of ocean eutrophication.

Artemia nauplii have been used as an important live food in almost all aquaculture hatchery productions. However, the supply of Artemia nauplii has been heavily reliant on cysts collected from the wild. Thus, many efforts have been undertaken to culture Artemia to produce cysts. Moreover, the use of adult Artemia as feed has started to gain attention. Artemia can be cultured at a relatively high productivity (ca. 2 tons per hectare per crop) in shallow ponds by using byproducts or waste as their feed. The protein content of artemia biomass is relatively high, e.g., a range of 51 to 61 percent DW, with a lipid content ranging from 5 to 10 percent DW.

Amphipods are another small crustacean that can grow rapidly in nutrient-rich areas. A recent study showed that amphipods cultured using microalgae and cow manure could be used as the sole food for Pacific white shrimp postlarvae.

Seaweeds

Some macroalgae (seaweeds) species have been studied intensively as feed raw materials, either as additives that contribute bioactive compounds such as flavonoids, prebiotics, and carotenoids, or as a source of macro- and micronutrients. Seaweeds are also known as effective nutrient biosorbents that remove various nutrients from their surrounding environment.

Members of the genus Ulva spp. are seaweeds with the greatest potential for aquafeed raw materials. These green macroalgae have a high annual productivity (~838 grams of carbon per square meter per year) and have the potential to be used as feed material and for other human uses. For instance, with its high total ammonia nitrogen (89 percent) and phosphate (44 percent) removal capacity, U. pertusa has the potential to be cultured as a phytoremediator in intensive fish or shrimp ponds, in coastal zones, and/or to be cultivated in integrated multitrophic aquaculture (IMTA) systems. The protein content of Ulva spp. may reach up to 32 percent DW, with a lipid content of <2 percent DW, and various species have been studied as a feed material for some aquaculture species, with a maximum inclusion level recorded at 25 percent.

https://www.aquaculturealliance.org/advocate/comparing-microalgae-blend-diets-to-reference-diet-for-nile-tilapia/

Gracilaria sp. is one of the most commonly cultured red algae. Members of this genus have been consumed and used to produce agar and can contain protein up to 18.9 percent DW with a lipid content of <1 percent DW (Xuan et al., 2019). The protein digestibility of Gracilaria vermiculophylla was reported to be about 87.8 and 51.4 percent in rainbow trout and Nile tilapia, respectively. The utilization of Gracilaria spp. for aquafeed has been tested in various aquaculture species, with the highest inclusion level reported in European seabass at about 25 percent.

Other studies of macroalgal genera in aquafeed have focused on some brown algae, such as Macrocystis spp., Ascophyllum nodosum and Sargassum spp. The inclusion levels of these macroalgae groups, however, were reported to be lower relative to Ulva or Gracilaria.

Microorganisms

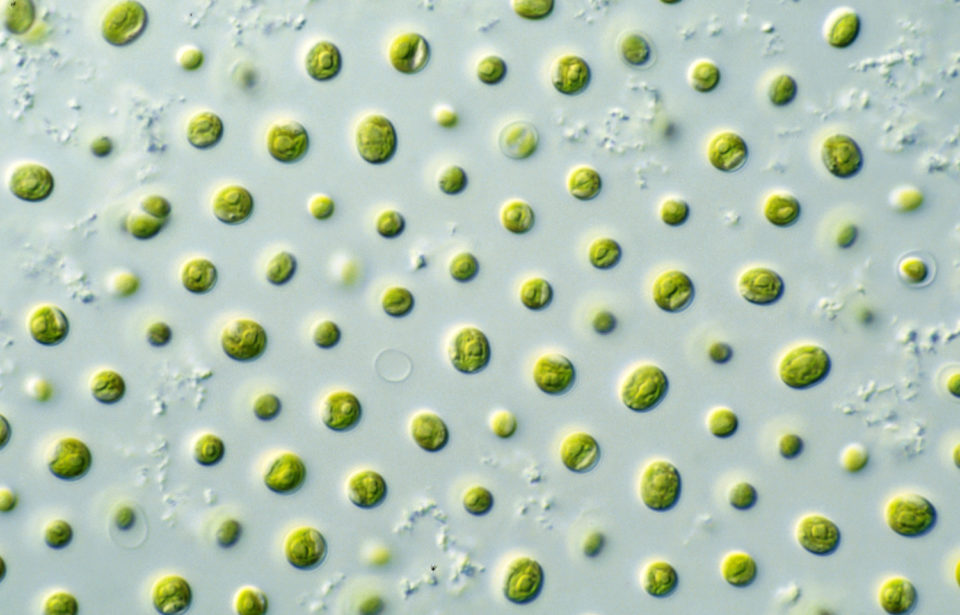

Materials of microscopic origin are derived from microorganisms such as microalgae, yeast, cyanobacteria and bacteria. Microalgae contain various essential nutrients such as amino acids, fatty acids, and vitamins as well as bioactive compounds that are beneficial for both aquaculture animals and humans. Various studies have recently demonstrated the possibility to generate microalgal biomass using wastewater, which might not be suitable for human uses but could be used as a feed material.

Among the extensively studied marine microalgae, several species that have a high potential as aquafeed raw materials include Nannochloropsis spp., Chlorella spp., Schizochytrium spp., Tetraselmis spp., and Isochrysis spp. Nannochloropsis spp. are known as a source of omega-3 highly unsaturated fatty acids (HUFAs) that can be cultured with high productivity (33.6 to 84.0 tons per hectare per year). The members of this genus could be used as an aquafeed material with an inclusion level up to 82 percent. A recent study showed that the use of defatted Nannochloropsis oculata (a byproduct of oil extraction for nutraceuticals) and whole cells of Schizochytrium sp. to substitute fishmeal and fish oil in Nile tilapia diet resulted in a 48 percent higher final body weight and 8 percent lower feed cost per kilogram fish production.

Arthrospira (Spirulina) spp. are cyanobacteria with substantial productivity (20 to 90 tons per ha per year) that has been cultured and used as food and feed supplements. With the high capacity in removing phosphate (99.97 percent) and nitrate (81.10 percent) in water, this group of cyanobacteria has the potential to be cultured in integration with other aquaculture production as a bioremediator. Arthrospira species are also known for their nutritional benefits. For example, A. platensis is reported to have a significantly high protein content (about 60 percent DW) and various high-value bioactive compounds including vitamins, essential lipids, and natural pigments. Arthrospira spp. have been tested on various aquaculture species with the highest inclusion level recorded in African catfish, at about 30 percent, and may completely substitute fishmeal use.

Although some marine yeast and bacteria have been identified recently, most of the studies involving these microorganisms as aquafeed raw materials are not specific to marine species. Commercially available bacterial meals are mainly produced from natural gas fermentation by using single or mixed species of methanotrophs, some of which can also be found in marine environment. Bacterial meal is a single-cell protein that can be used in the diet of various animals including aquaculture species.

A notable aquafeed raw material is biofloc meal, which mainly consists of a heterogenous mix of bacteria. Biofloc can be generated from fish or shrimp wastewater treatment and has a protein content in the range of 23 to 49 percent DW. This material could be used in shrimp feed at an inclusion level up to 60 percent.

Challenges

The utilization of marine-based organisms for feed material is not without challenges. The use of each material is associated with specific challenges that may limit its use in aquafeeds; these include (1) nutritional composition and productivity, which may strongly depend on the environment; (2) risk of contamination by toxins and heavy metals; and (3) presence of antinutritional factors.

The productivity and nutritional composition of macroalgal- and microbial-based materials could be strongly dependent on the nutrient quantity and composition of the water, which are site and season specific. Likewise, the productivity and nutritional composition of mussels could depend on the quantity of organic matter, microalgal composition, and the presence of stressors in their environment. This implies that site selection is an essential strategy to maintain high productivity and high quality of marine-based raw materials. Nutrient-rich environments are also associated with the higher possibility of toxin and heavy metal absorption by extractive marine organisms, which may reduce the safety of the raw materials.

Fermentation and biorefinery technologies that have been well-developed in various food technologies could be applied to these materials to improve their nutritional value and to optimize nutrient digestibility as well as eliminate potential hazards. While some of these raw materials, particularly those of macroalgal origin, are typically lower in protein than current sources; the development of protein concentrates for emerging ingredients may help bolster their use in future aquafeeds. Various processes could be applied to these materials to remove possible contaminants such as heavy metals and toxins to ensure their safety for the fed organisms and ultimately for human consumption.

Conclusions and future directions

Many marine-based feed materials are promising ingredients for aquafeed development. From a nutritional point of view, many marine-based materials are relatively similar, if not superior, to terrestrial-origin materials. The production of unfed marine-based materials does not require freshwater and may enable the retrieval of waste nutrients from the environment, thus allowing more efficient use of nutrients, reducing the negative impacts of aquaculture on the environment, and promoting the sustainability of marine aquaculture in general.

Some of the marine-based, feed raw materials are already available commercially, such as seaweeds, microalgae, or bacteria meals; however, the price of these products is still high and is not competitive with other, more conventional feed materials. Thus, technologies must be developed for the production and processing of these materials to enable their commercial use. Further research on the environmental and nutritional requirements of these organisms is also needed to improve productivity, and to elucidate strategies to enhance the nutritional quality of these materials.

The development of pre-treatment and processing technologies will reduce the risks of contamination and antinutritional factors as well as improve the nutritional quality of the products. Biorefinery technologies that could allow the utilization of all valuable constituents of a raw material in an economically feasible, cascading process, with limited to zero waste, could be developed for the efficient production of many high-quality materials for aquafeed production.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Dedi Jusadi, Ph.D.

Department of Aquaculture

Faculty of Fisheries and Marine Sciences

Bogor Agricultural University

Bogor, Indonesia -

Julie Ekasari, Ph.D.

Corresponding author

Department of Aquaculture

Faculty of Fisheries and Marine Sciences

Bogor Agricultural University

Bogor, Indonesia -

Muhammad Agus Suprayudi, Ph.D.

Department of Aquaculture

Faculty of Fisheries and Marine Sciences

Bogor Agricultural University

Bogor, Indonesia -

Mia Setiawati, Ph.D.

Department of Aquaculture

Faculty of Fisheries and Marine Sciences

Bogor Agricultural University

Bogor, Indonesia

-

Ichsan Achmad Fauzi, Ph.D.

Department of Aquaculture

Faculty of Fisheries and Marine Sciences

Bogor Agricultural University

Bogor, Indonesia

Tagged With

Related Posts

Intelligence

10 takeaways from GOAL 2019 in Chennai, India

The Global Aquaculture Alliance held its GOAL conference in Chennai, India, and recruited a host of experts in various fields to share their expertise.

Intelligence

Byproduct utilization for increased profitability, part 3

Fish protein hydrolysates obtained from fish-processing wastes can be used to make valuable ingredients for the food and healthcare industries. Hydrolysates are produced from fish muscle and viscera through an autolytic process by endogenous enzymes or an accelerated method using exogenous enzymes.

Health & Welfare

Chem-free fixes emerging in sea lice saga

Salmon farmers, using emerging technologies, are exploring new methods of sea lice mitigation in an effort to overcome one of the industry’s most persistent problems. New chemical-free innovations show an industry eager to adapt and adopt environmentally safe practices.

Aquafeeds

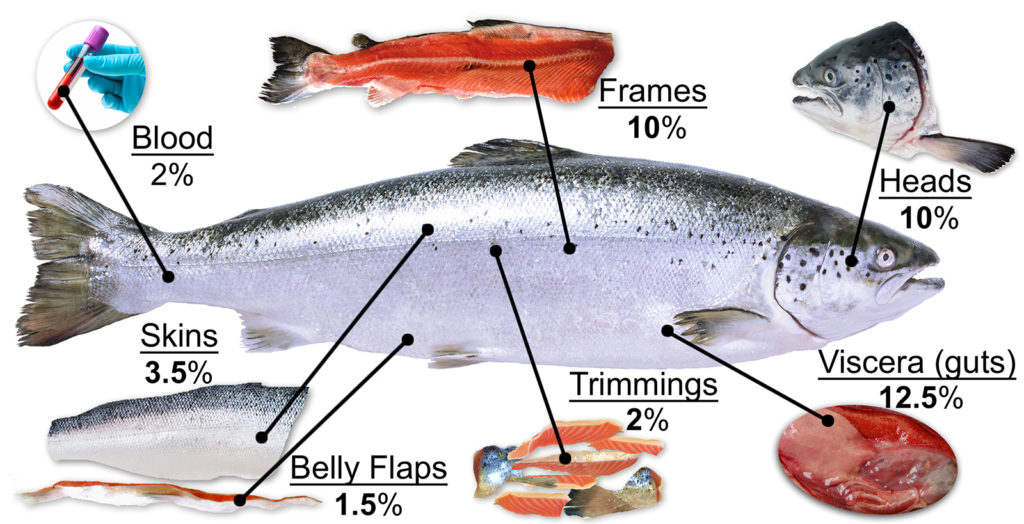

It takes guts to advance sustainability in aquaculture

With byproducts representing between 25 to 50 percent of the weight of various fish species, we need to be looking at how the entire fish is being used: even the heads, guts and skin.