Whoosh Innovations is putting pneumatic tubes to the test, transporting fish in both wild and farmed environments

As the aquaculture industry becomes increasingly concerned with fish welfare and doing all it can to mitigate stress-inducing factors, Seattle-based Whooshh Innovations is providing comfortable rides.

Whooshh uses pneumatic tubes to glide fish like farmed or wild salmon effortlessly to their destinations, whether it’s from a net pen to a holding area or through a blocked river passage. The technology directs them by deploying a scanner that uses artificial intelligence (AI) to recognize their species and size.

Founded in 2007, the company’s initial focus area was fruit. It developed a harvester that used pneumatic tubes to pick fruit off of trees, saving hours of physical labor spent handpicking fruit and moving ladders from tree to tree. The harvester was equipped with a scanner that separated fruit destined for the market from fruit destined for processing. With that mission accomplished, co-founder Vince Bryan, a lawyer who had worked for Adobe Systems and was keenly interested in software and its ability to solve problems, turned his thoughts to fish.

Wondering if pneumatic tubes would be a better way to move fish around, he engaged Norwegian fish processor Vikenco in a pilot project in 2011. He ran a pneumatic tube through the company’s plant to an adjacent building outside, using the tubes to move recently harvested fish from one building to the other.

“We were able to automate a process that had previously been quite labor intensive, and we realized we could move anything through the tube if it was appropriately sized,” he said.

While in Norway he learned the aquaculture industry was abuzz with concerns for fish welfare and the importance of having unstressed fish. “We learned that when fish were in a sea pen prior to harvest, they were crowded, which was stressful for them. Then they were sucked into a big pipe and exhausted themselves fighting against the current that was trying to pull them through. When fish are stressed and exhausted, they release enzymes and their cortisol levels go up – factors that affect their taste and their shelf life.”

Whooshh partnered with AquaGen Atlantic Salmon and the European research organization SINTEF on a three-year study culminating in 2016 and was able to prove that fish passing through pneumatic tubes weren’t stressed.

“The tubes are coated with a layer of water, and by changing the pressure inside the tubes, the fish glide through instead of being sucked in,” he said.

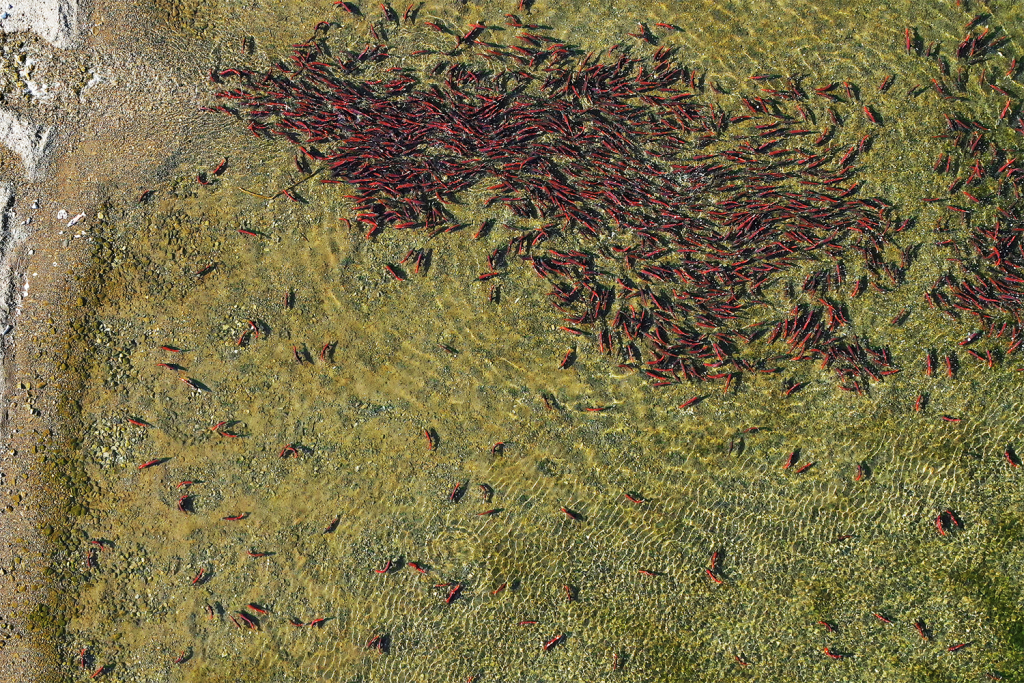

Closer to home, Bryan was exploring other uses for his pneumatic tubes in the state of Washington, specifically, the process of moving broodstock from a sea pen into inland tanks where eggs are extracted. Typically, it was a labor-intensive process with high levels of fish stress and mortality. Working with the Washington Department of Fish & Wildlife and the Yakama Nation Fisheries, Whooshh installed its systems on the Yakama and Washougal Rivers, using pneumatic tubes to connect a fish trap to a transport truck that would drive fish to the hatchery.

“It reduced the time and handling of the fish compared to trap and trawl, which was less stressful for the fish and easier for the people working these jobs,” he said. “It also reduced the fish mortality levels and increased fecundity as fish were coming in from the sea to spawn.” Both the state and Yakama nation bought the technology in 2014 and uses it to this day during the salmon runs.

Convinced his pneumatic tubes were a good fit for the aquaculture industry, Whooshh’s next task was to adapt its agricultural sorting scanner so it could be used to scan fish. The company started work on this in 2015 and by 2018 the Passage Portal was ready for deployment: a scanner able to distinguish hatchery fish from wild or invasive fish and scan up to 40 fish per minute, or 56,400 fish per day. “As fish exit the scanner there are a series of gates that open or close depending on its destination, and they’re pneumatically transported to their destination,” he said.

In 2018 the company did a demonstration at the Chief Joseph Dam, a 235-foot-high head dam on the Columbia River in the state of Washington, to show its technology worked. The Passage Portal was floated in and built offsite in a streamlined process that eliminated civil work and reduced the permitting time significantly. “We worked with federal agencies and they were amazed that it took us just six months from concept to deployment,” said Mike Messina, a spokesman for the company.

The fact that there’s so many dams in place means there needs to be a quick, easy way to get fish into their spawning habitats, and that’s what this technology was built for.

In 2020, its first installation was done at Big Bar, British Columbia, where a landslide had created a natural dam.

“We could not have had a more difficult site,” Bryan said. “It was an extremely tight time frame with freezing temperatures, no power on site and rock fall happening all around!”

Working with the Department of Fisheries & Oceans (DFO) and the Yinka Dene Alliance, a coalition of six First Nations affected by the landslide, Whooshh installed a Passage Portal that rapidly transported thousands of fish over the landslide. The company was able to go from concept to deployment in three months.

Today, Whooshh Innovations has raised $26 million in grant money, angel investment and crowdfunding, and has 18 clients in the United States, Norway, Sweden, Scotland and Canada. Because its systems are modular and can be easily tailored to different applications, clients are using different components to suit their needs. Some are using the pneumatic tubes to move broodstock, others are transporting fish from one raceway to another in a hatchery, and others still are using the Passage Portal to scan, sort and gather data on fish and to move them over and past barriers like dams.

Whooshh’s AI scanning technology is also being used to reduce the presence of invasive species. In Illinois, the company has deployed the Guardian, essentially a floating barge containing its FishL Recognition System™ to remove invasive Asian carp from the Illinois River.

“The invasive species occupy over 80 percent of the biomass in the Midwest rivers, and the concern is that they’re really close to the Great Lakes,” said Messina. Until recently, invasive carp have been harvested and removed by large nets installed in sections of the waterways, but native species pay the price as bycatch. “A better way than blocking the fish is to use choke points to remove the invasive species from the river and redirect them so they can be used for food for people, pet food and fertilizer,” Messina said.

The company’s future growth will come from moving fish over dams, he said. “The Passage Portal costs between $2 million and $7.5 million depending on the number of tubes required and the size of the dam. When you compare that cost to other methods of getting fish over dams, like a fish ladder on a high head dam, you’re talking about tens of millions of dollars and an awful lot of time. Because we’re portable and modular, we can deploy in months and be moving fish rapidly.”

Messina noted that there are some 85,000 dams in the United States alone, most of them built for irrigation or flood control.

“The fact that there’s so many dams in place means there needs to be a quick, easy way to get fish into their spawning habitats, and that’s what this technology was built for,” he said. “Our systems provide a solution that allows fish to continue in their migratory journey without being touched by human hands.”

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Lauren Kramer

Vancouver-based correspondent Lauren Kramer has written about the seafood industry for the past 15 years.

Tagged With

Related Posts

Fisheries

As Yukon Chinook salmon populations decline, researchers turn to technology for answers

Using drones, researchers seek to better understand where, along an almost 2,000-mile migratory route, things go wrong for Chinook salmon.

Innovation & Investment

‘AI ticks all the boxes’ and is proving to be a perfect match for aquaculture

Artificial intelligence (AI) is rippling through the aquaculture industry, promising greater efficiencies and insights, as well as investor interest.

Innovation & Investment

Aqua Insights excerpt: Smart water quality sensors for aquaculture

An excerpt from the April 2022 issue of Aqua Insights looks into the possibilities that Smart water quality sensors provide aquaculture.

Innovation & Investment

Net gains in aquaculture net technology

The aquaculture industry is paying greater attention to net technology, in terms of materials and maintenance, because of its impact on the bottom line.