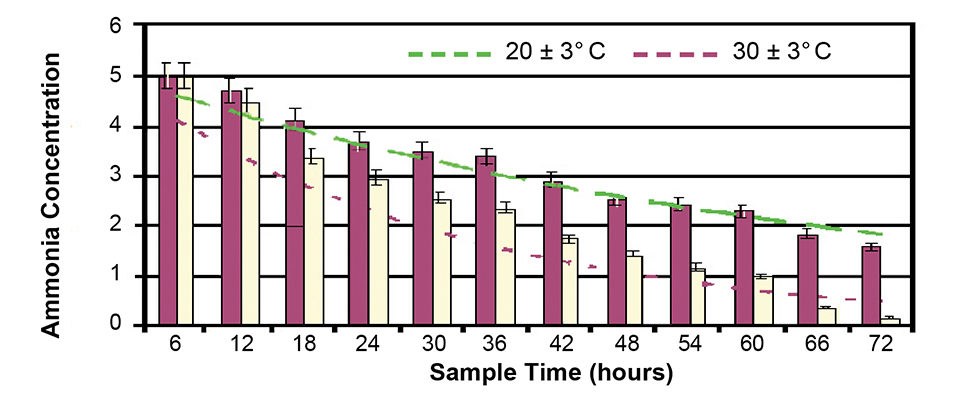

Spectrophotometer determined rate of ammonia decay over time

Recirculating aquaculture systems face the need to be more efficient than ever for production to increase with profit. This need and the demand for complementing fishing from natural habitats emphasize design improvements in existing systems.

A key element in recirculation systems is the biofilter, which is strategic to controlling ammonia concentrations below toxic levels and maintaining a cost-effective and profitable system. Biofilters therefore need to be optimized to increase production capacity and reduce the risk of mortality in varying environmental temperature conditions.

Temperature study

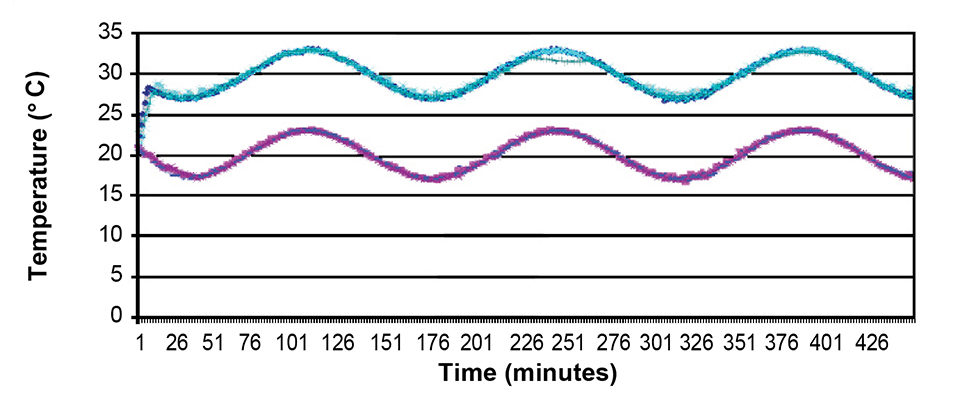

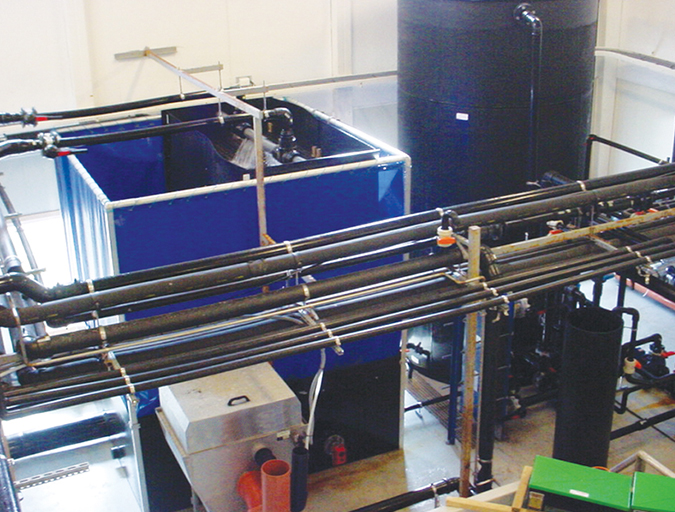

In a recent study, the authors set up a series of temperature-controlled tank systems to determine the effects of temperature variation on biofilter performance. The biofilters, which were custom designed to fit into the tanks as self-contained systems, were positioned independently and loaded with synthetic ammonia substrate feedstock. They were then exposed to temperature regimes of 20 ± 3 and 30 ± 30 degrees-C over a 72-hour period.

A computer-automated temperature-control system with independent 40-liter tanks was used for the experiment. Two triplicate batches of six tanks total were used to subject the biofilters to the two temperature regimes (Fig. 1). The biofilters were acclimated before sampling. The samples were analyzed using a spectrophotometer to determine the rate of ammonia decay over time at each temperature regime.

Results

A reaction kinetics decay curve was plotted for the ammonia decay over time for both regimes (Fig. 2). At P < 0.05, the decay coefficients indicated the decay rate was higher at 30 ± 30 degrees-C. This may support further, in-depth study of temperature fluctuations in relation to biofiltration for future system designs.

(Editor’s Note: This article was originally published in the November/December 2008 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Milton Saidu

Department of Biological and Agricultural Engineering

Louisiana State University

Agriculture Center

Baton Rouge, Louisiana 70808 USA -

Steven G. Hall, Ph.D.

Department of Biological and Agricultural Engineering

Louisiana State University

Agriculture Center

Baton Rouge, Louisiana 70808 USA -

Troy Davis

Department of Biological and Agricultural Engineering

Louisiana State University

Agriculture Center

Baton Rouge, Louisiana 70808 USA

Tagged With

Related Posts

Health & Welfare

Biofilter inoculation in recirculating aquaculture systems

Biological filters are essential parts of recirculating aquaculture systems that transform toxic fish compounds such as ammonium and nitrite into less-harmful nitrate. The authors tested the convenience and efficiency of three methods for the initial inoculation of aerobic biofilters.

Responsibility

Biofilter start-up problems? Just add sugar!

One way to jump start biofilter operation is by adding sugar, which can provide sufficient organic carbon to neutralize the ammonia-nitrogen produced.

Innovation & Investment

Estimating biofilter size for RAS systems

Controlling total ammonia-nitrogen (TAN) concentrations is the primary concern when sizing a biofilter for use in a recirculating aquaculture system. Sizing decisions are best based on previous experience with a given biofilter media in a specific biofilter configuration.

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.