Efficient feed utilization brings maximum growth, survival, profitability

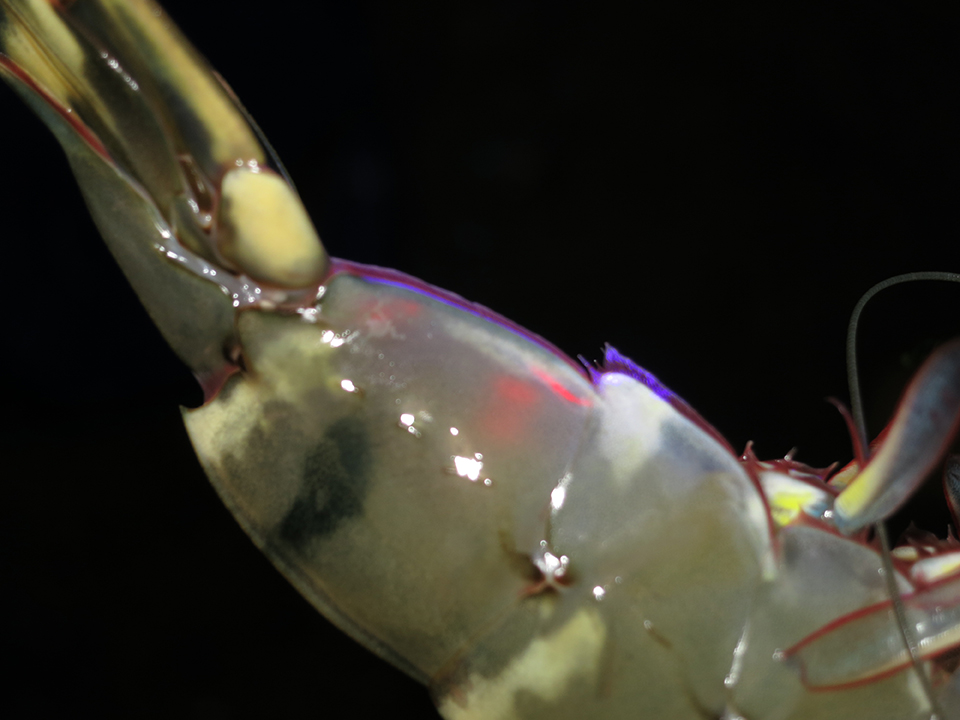

Traditionally, live foods such as diatoms and Artemia sp. have been used for rearing the zoeal and mysid stages of penaeid shrimp. However, live feeds are costly, variable in quality, and a potential source of disease contamination. Artificial diets are increasingly being used to deliver a balanced nutrient profile in a cost-effective and biosecure manner.

As shrimp develop through the larval stages, they undergo changes in gut structure, digestive enzyme production, and feeding behavior. Specialized larval diets are required to supply these unique requirements.

In the past, larval diets were simply microparticulate forms of conventional grow-out diets. Little attention was paid to issues of digestibility, water stability, and leaching. Poor performance frequently related to nutrient loss before ingestion and low digestive capacity in postlarvae after metamorphosis.

Recent advances in feed formulation, manufacturing, and delivery techniques have overcome this problem. Artificial diets can now be as nutritionally efficient as natural diets for larval shrimp after metamorphosis is completed.

Feed factors

Though the production of artificial larval feeds includes various key criteria, particle size and water stability are considered the most important. To assure the proper mix of nutrients in a single larval feed particle, ingredients must be milled to a very small size. Because nutrient leaching becomes more difficult to control as surface area: volume ratios increase with decreasing particle size, manufacturers use special binders that hold the product together but do not interfere with digestibility.

Until recently, excessive losses from leaching, compounded with sub-optimal nutrient composition and poor digestibility of inert feeds, precluded complete replacement of live organisms such as artemia nauplii in shrimp larviculture. To reduce losses due to leaching, aquafeed manufacturers have developed microencapsulation techniques.

Microencapsulation

Microencapsulation is a process by which tiny parcels of liquid or solid active ingredient are packaged within a second material for the purpose of shielding the active ingredient from the surrounding environment. In the case of larval diets, microencapsulation is used to protect water-soluble nutrients from leaching. These capsules can range in size from 1 μ to 7 mm.

There are several mechanisms by which the core material (i.e., nutrients) can be released from a microcapsule: through mechanical rupture or dissolution of the capsule wall, or, less commonly, through release mechanisms such as biodegradation and slow erosion of the outer shell. One of the recent advances in larval feed technology utilizes complex particles consisting of lipid-walled microcapsules embedded within a matrix bound together by gelatin and alginate.

Liquid supplements

Leaching studies have shown that dry particles suffer high loss of nutrients in the initial minutes after immersion, before hydration can reduce porosity. Liquid diets offfer the opportunity to deliver completely hydrated particles with proper size and texture.

Feed manufacturers face a difficult challenge in mimicking the soft texture, neutral buoyancy, membrane-bound exterior, and digestible nutrients within live diets. The use of liquid diets allows a close approximation of these physical characteristics.

Liquid diets are formulated as completely balanced diets, with high energy ration that nourishes zoea through postlarval stages. To ensure uniform dispersion, the feeds have minimal surface friction, and the microcapsules’ soft, moist texture makes them easy to consume.

The ingredients are selected for high quality, attractability, digestibility, and freedom from pathogenic shrimp viruses such as white spot syn-drome virus. Manufacturers use cold processes to preserve sensitive nutrients, pigments, omega-3 fatty acids, enzymes, and other nutrients naturally present.

Acclimation diets

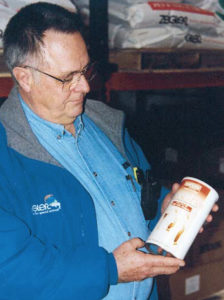

Today, the use of acclimation diets (for high-stress periods when postlarvae are transported to the pond for stocking) or raceway diets is a common practice among shrimp farmers. In addition to being premium diets, these feeds are formulated with extra-high vitamin levels and added immunostimulants for enhanced growth and survival.

Since each of these diets is especially formulated to simulate the biochemical composition of artemia, their advantages begin with a reduction in the amount of artemia used to raise the postlarvae, which saves money. There is also less dependence on unpredictable artemia resources, and reduction in the labor and facilities costs related to hatching artemia cysts. In addition, the products have first-rate bioavailability and are completely biosecure.

Conclusion

The technologies now being commercialized in feed supplement production offer improvements beyond just satisfying the nutrient requirements of farmed animals. Encapsulation, in particular, holds much promise for raising the shrimp industry to a new level of efficient feed utilization that will bring in maximum growth, survival, and profitability.

(Editor’s Note: This article was originally published in the April 2001 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Sergio F. Nates, Ph.D.

Zeigler Bros., Inc.

Tagged With

Related Posts

Innovation & Investment

Artemia, the ‘magic powder’ fueling a multi-billion-dollar industry

Artemia, microscopic brine shrimp used as feed in hatcheries, are the unsung heroes of aquaculture. Experts say artemia is still inspiring innovation more than 50 years after initial commercialization. These creatures are much more than Sea-Monkeys.

Health & Welfare

Asepsis key to prevent contamination in shrimp hatcheries

Maintaining biosecurity and asepsis in larval shrimp production is a key component of the production chain in Ecuador, which requires the production of 5.5 billion larvae monthly from 300-plus hatcheries.

Health & Welfare

Bacillus probiotics improve hatchery, nursery production in EMS-hit Mexico

In early 2014, a trial to evaluate the effects of a mixture of Bacillus strains on early mortality syndrome bacteria during the larviculture and nursery phases for shrimp was carried out at a commercial hatchery in Mexico.

Health & Welfare

Brunei project develops technology for large black tiger shrimp production, part 3

Specific pathogen-free offspring developed from founder populations of P. monodon collected from Brunei coastal waters were introduced into a biosecure breeding program, where they have been reared to the fifth generation using family-based selection for reproduction and growth.