New equipment offers alternative to manual processing

Having proved they can farm and deliver significant quantities of raw, shell-on shrimp, farmers in Asia, Latin America and elsewhere are now looking to increase profits by adding value to their shrimp products. More and more are peeling, deveining, cooking, and packaging greater percentages of their product.

For those operations wishing to add value, one of the first decisions to be faced is the choice of peeling method. The peeling process can have a significant effect on the quality, and therefore value, of the end product.

Growers of warm-water shrimp typically apply one of two major methods to remove the shells from their shrimp: hand peeling or automated machine peeling. Although small manual machines that cut shells to facilitate peeling, but do not fully peel, are available, their use is limited.

Hand peeling

Because of a lack of start-up capital, plus an abundant supply of cheap labor, shrimp farmers in developing countries often choose to peel by hand.

Due to increasing concerns about quality and compliance with HACCP norms, the technology of hand peeling has improved. Workers in hair nets, gloves, mouth masks, protective smocks, and rubber boots walk through foot-dip solutions on their way to stainless-steel tables and conveyors at enclosed, temperature-controlled work stations in relatively modern buildings.

Depending upon shrimp size, accomplished hand peelers can average 6 to 12 shell removals per minute. Quality can vary greatly, depending upon the skill of the individual peeler. In addition, because of the human handling involved, the potential for contamination always exists.

Individual machine peeling

As labor costs increase and concerns for consistent quality and food safety grow, some shrimp farmers and processors are turning to individual machine-peeling systems.

“The fewer hands touching the shrimp, the cleaner it will be,” said Frank Heurich, president of Gregor Jonsson, Inc., the world’s only major manufacturer of individual shrimp-peeling systems.“The faster it is processed, the less time and temperature abuse results.”

Located in Highland Park, Illinois, USA, Gregor Jonsson has been manufacturing and marketing automatic shrimp-peeling systems in the United States and around the world more than 50 years.

Gregor Jonsson systems can handle any species of wild or pond-raised warm-water shrimp from 10 to 90 count. They can process shrimp tail-on round, butterfly split, western style, EZ-peel, or completely peeled and deveined, removing the tail.

“If it can be peeled by hand, we can peel it by machine,” Heurich said. “The key to maintaining product quality is individual processing.”

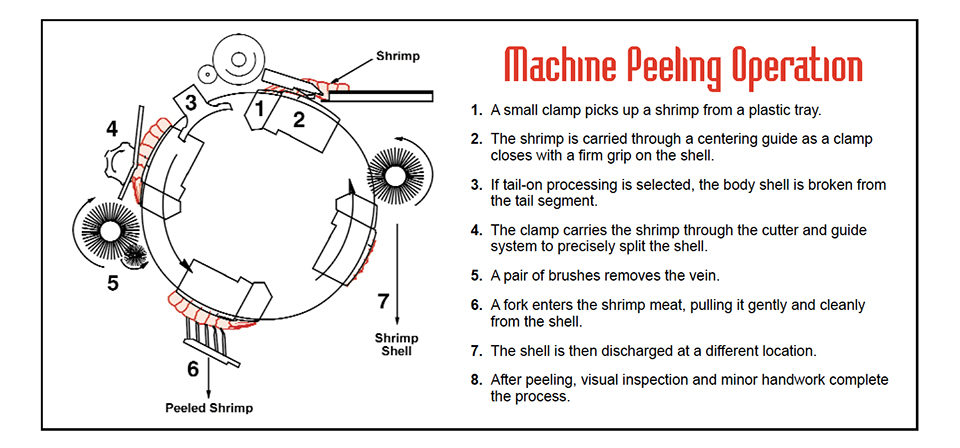

The peeling machines automatically adjust to each shrimp, peeling and deveining it in the style selected. Workers place shrimp manually in the trays, and the rest of the process is automatic.

The company claims its systems can peel shrimp up to 10 times faster than hand peeling. At maximum productivity, the two peeling station models operate at uniform rates of 5,000 or 6,000 shrimp per hour, or 4,000 or 5,000 shrimp per hour. The slower speeds are recommended for tail-on processing. Sample machine productivity is shown in Table 1.

Basic system options

Jonsson peelers are available as standard systems or water conservation systems. Each type offers advantages to meet individual customer requirements and local economic conditions.

With standard systems, peeled shrimp and shells drop from each peeling station onto stainless steel flumes. Water then moves the shrimp from several stations to a single inspection conveyor, and shells to a collection conveyor. A single-station, full-time standard system uses 9.7 liters of water per minute at 2 bar and 11.7 liters per minute at 3 bar.

No flumes are used in the water conservation systems. At each peeling station, the machine discharges peeled shrimp onto an inspection conveyor exclusive to that station. No water is used to move the shrimp. Water use can be as much as 70 percent less than in a standard system. Either system can be arranged in single, double, or multiple lines.

Investment

Utlizing standard components, the peeling systems are customized to answer customers’ total volume, capacity, and peeling style requirements. Modular design and construction enable the systems to be expanded economically as needs grow.

With the current low value of the U.S. dollar, the smallest individual machine peeling system starts at a price below U.S. $20,000. Returns on investment from improvements in product quality, efficiency and reduced labor costs are factors that must be considered in purchasing decisions.

(Editor’s Note: This article was originally published in the February 2005 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Beth A. Dancy

Vice President – Sales

Gregor Jonsson Inc.

1520 Berkeley Road

Highland Park, Illinois 60035 USA

Tagged With

Related Posts

Responsibility

Intelligence, integrity in the fight against forced labor in seafood

In previewing the SeaWeb Seafood Summit, the Advocate examines human rights in the supply chain and the people who advance solutions in rooting out worker abuses. In part one of a three-part series, Environmental Justice Foundation co-founder Steve Trent talks about linking environmental security with human rights.

Responsibility

Technology, diligence in ensuring abuse-free seafood supply chains

The Advocate is highlighting people who advance solutions in social responsibility. In part two of a three-part series, Katrina Nakamura of Sustainability Incubator discusses identifying hot spots for abuses and taking steps to eliminate high-risk products.

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.

Aquafeeds

Algae alternative: Chlorella studied as protein source in tilapia feeds

Chlorella and other species have potential as protein sources in aquafeeds. In trials with tilapia fry raised in a recirculating system, the fish received a fishmeal-based control diet or feeds with portions of the fishmeal replaced by Chlorella.