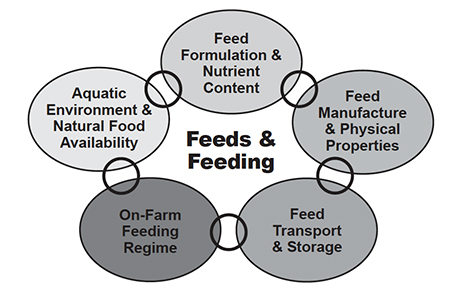

Performance of feed and feeding regime only as good as the weakest link in a series of processes

In a global economic environment of decreasing shrimp prices and increasing raw-material costs, efforts to reduce feed costs and improve their management are at the top of the agenda for most shrimp farmers. Since feeds and their management generally represent major operating cost items, aquafarmers need to understand the five key factors that determine the nutritional performance and economic success of formulated aquafeed.

Formulation and nutrient content

The first key aspect to producing good-quality aquafeed is to source good-quality feed ingredients. These feed ingredients need to be blended through formulation to provide an available nutrient profile that approximates the known dietary nutrient requirements of the target species for the intended farming system. Sadly, little practical information exists concerning the dietary requirements of shrimp under practical farming conditions.

Manufacture and physical characteristics

The feed-manufacturing process includes several steps: ingredient grinding, feed preconditioning, feed-forming method (microencapsulation, steam pelleting, extrusion pelleting, cold pelleting, etc.), feed postconditioning and drying (including top-dressing), and feed bagging and handling prior to sale.

The most important physical characteristics of the manufactured aquafeed include feed particle size, shape, texture, density, color, palatability, and buoyancy. Stability in water on prolonged immersion, which includes the susceptibility of the ingredients to nutrient loss through leaching, is also important.

Feed transport and storage

To maintain feed quality, consider the transportation conditions from the feed manufacturer to the farm. These conditions include the transportation method (road, rail, ship, or air), duration, and possible direct exposure of feed to sunlight, rain, and changing temperature and humidity.

The way feed is stored on the farm before use can significantly affect its quality. It is important to understand that manufactured feeds are highly perishable products with a finite shelf life, and should be stored accordingly. This includes using specialized storage facilities for large quantities of feeds within a feeds warehouse, and a smaller storage facility (i.e., shed, silo, bins, etc.) near the production ponds, tanks, or raceways.

Feeding regime

Feed application methods include manual or automated broadcasting from boats, levees, or submersible feeding trays. Mechanized feeders with blowers are gaining acceptance in many areas.

Feeding rate and frequency refers to the quantity of feed applied and its timing, including intervals between successive feedings and the criteria used to establish feeding rates (feeding tables, water quality, appetite, experience, etc.).

Finally, the methods for monitoring feed consumption and shrimp growth/survival, include the use of periodic animal sampling (mostly through cast-netting), direct visual inspection, or feeding trays.

Aquatic environment and natural food

The conditions of the aquatic environmental are also very important. These involve water quality and management of water temperature, dissolved oxygen concentration, dissolved mineral concentrations, and water exchange. Aeration methods, solids management, general rearing environment, and undue stress that results from disease, animal predation, and/or human activities are additional factors.

Natural food availability is critical because shrimp derive a significant portion of their nutrition from natural production. This availability depends on shrimp density, fertilization regime, water exchange, and ambient climatic conditions, among other conditions.

Conclusion

Shrimp feeds and their management can be viewed as a chain of linked, interdependent processes, where each step or component supports the next one. Although nutritionists, feed manufacturers, farmers, and others have different opinions regarding the key factors that govern the success of a diet or feeding regime, most agree that it results from a series of linked processes, and that the ultimate performance of a shrimp feed and feeding regime will only be as good as the weakest link.

(Editor’s Note: This article was originally published in the June 2002 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Albert G.J. Tacon, Ph.D.

Aquatic Farms Ltd.

49-139 Kamehameha Highway

Kaneohe, Hawaii 96744 USA

Tagged With

Related Posts

Aquafeeds

Aquaculture’s input efficiency shines as FIFO ratios improve

The latest Fish In:Fish Out (FIFO) ratios calculated by IFFO – The Marine Ingredients Organisation shows that every kilogram of wild fish utilized in aquafeeds results in a total of 4.55 kilos of farmed fish produced.

Aquafeeds

Fishmeal, fish oil replacements in sea bream, sea bass diets need nutritional compensation

Fishmeal and fish oil replacements present a challenge for the aquafeed industry. The range of alternative protein and fat sources is limited, given multiple considerations.

Aquafeeds

How much fish is consumed in aquaculture?

Traditionally accepted calculations of wild fish use in feed for major farmed species tend to misrepresent fishmeal use. Some more current calculation methods require separate calculations for fishmeal and fish oil, or focus on quantity of protein from wild-caught fish.

Aquafeeds

Report reviews feed practices in shrimp aquaculture

New feed practices can reduce environmental impacts of shrimp farming, including the replacement of fishmeal and fish oil with sustainable lipid sources.