Successful, integrated industry provides export income, jobs

Shrimp farming in New Caledonia – a French Overseas Territory located in the Pacific Ocean about 2,500 km northeast of Brisbane, Australia – began in 1970 at the Saint Vincent Station and operated by the South Pacific Commission (CPS) and FAO. The New Caledonian Association for the Development of Aquaculture (AQUACAL) took over management of the Saint Vincent Station in 1973, and IFREMER became the scientific and technical director of the Association. The first small-scale shrimp farm (Ferme Chevallier) was established in 1981, and the first industrial farm (SODACAL) in 1983. The first shrimp meal factory (SICA) was set up in 1984, and the first private hatchery (SODACAL) hatchery and packing plant to export in 1988.

Production has grown steadily and reached around 2,000 tons in 1999. Currently, the shrimp-farming sector includes ten farms (450 ha of ponds), four hatcheries and two shrimp meal plants, (SICA and MSV), and one packing plant (SOPAC) that exports mainly to France, Japan and Australia. The industry is organized through a network into a professional association, the GFA (Groupement des Fermes Aquacoles de Nouvelle Calédonie). Shrimp farming has an important economic impact, through exports (currently the second most important export item) and by providing jobs in rural areas.

Lucien-Brun, Annual shrimp production, Table 1

| Year | Production (mt) |

|---|

Year | Production (mt) |

|---|---|

| 1986 | 65 |

| 1987 | 87 |

| 1988 | 217 |

| 1989 | 296 |

| 1990 | 539 |

| 1991 | 648 |

| 1992 | 733 |

| 1993 | 632 |

| 1994 | 691 |

| 1995 | 878 |

| 1996 | 985 |

| 1997 | 1,107 |

| 1998 | 1,569 |

| 1999 | 1,906 |

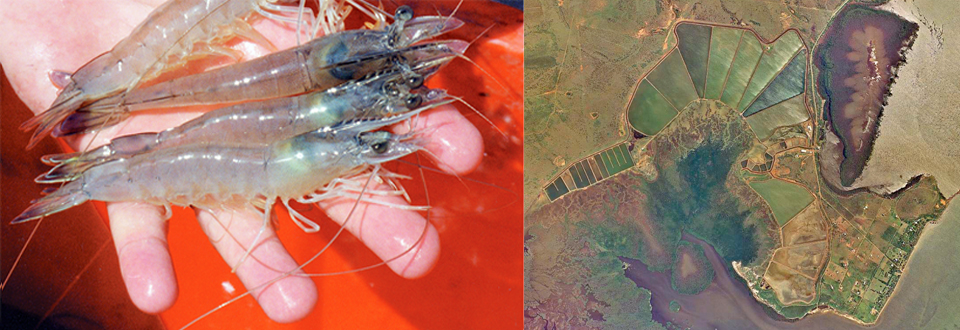

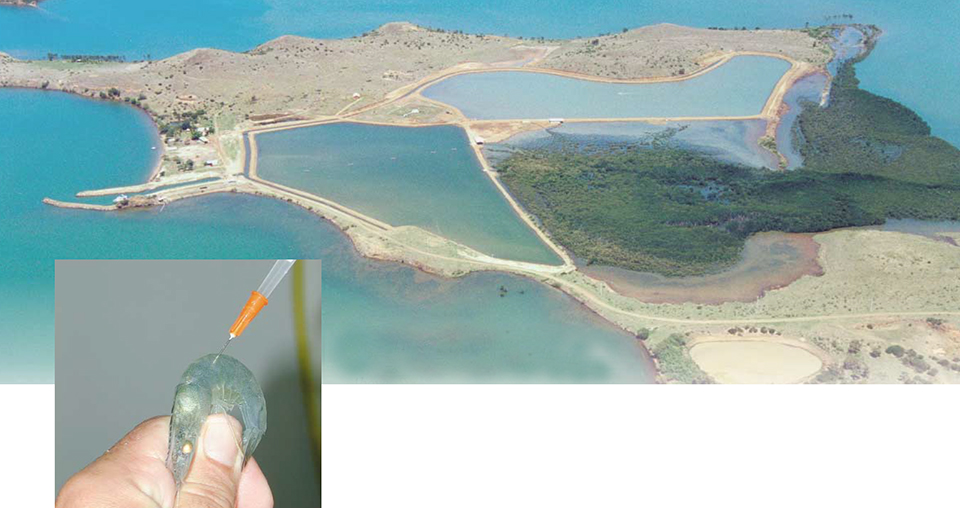

Species, seedstock production

Initially it was necessary to select a shrimp species that would perform well under local climatologic conditions, but none of the local species produced adequate growth or survival. Eventually it was determined that the best species was a Mexican strain of Penaeus stylirostris brought in from Arizona. Since its introduction, shrimp farmers have produced their own broodstock and more than 30 generation have been produced in captivity, New Caledonia was one of the first countries to develop an industrial shrimp farming industry based on domesticated broodstock, and today, its growth performance is superior to that of the original strain. It also shows some specific IHHNV resistance. Hatcheries implement mostly AQUACOP techniques including artificial insemination. Some hatcheries use only microparticulated diets and artemia, and no microalgae.

Farms

Shrimp farm design in New Caledonia is adapted to its very irregular shoreline and to respect the environment (including mangroves) and avoid encroachment. All farms are located on the West coast and behind the mangrove area. Availability of suitable land was limited, so large farms – like those found in Latin America – have not developed. Seawater used has a high productivity that is reflected in pond natural production.

Existing farms can be classified into three types: three farms under 20 ha (8 percent of total area, 6 percent of total production), five farms from 20 to 50 ha (43 percent of total area, 48 percent of total production), and two farms with more than 50 ha (48 percent of total area, 47 percent of total production). Aerated ponds (44 percent of total area, 53 percent of total production) have an average area of 3.8 ha and non-aerated ponds average 8.5 ha. Sample production is shown in Table 2.

Lucien-Brun, Area and production, Table 2

| Shrimp Farm | Pond Area (ha) | 1999 Production (mt) |

|---|

Shrimp Farm | Pond Area (ha) | 1999 Production (mt) |

|---|---|---|

| Aquamer | 40.6 | 174.2 |

| Aquamon | 42.9 | 165.0 |

| Bassns Dumbea | 19.0 | 25.0 |

| Blue Lagoon Farms | 83.0 | 403.9 |

| FAO | 7.8 | 34.0 |

| Peneide de Ouano | 35.0 | 161.5 |

| SASV | 7.4 | 21.9 |

| Sea Farm | 34.2 | 127.9 |

| SODACAL | 129.0 | 564.6 |

| Ferme Webuihoone | 44.7 | 186.7 |

| Ferme Tournier | 11.0 | 41.2 |

| Total | 454.0 | 1,905.9 |

Seasonality

The industry is limited by the cool season. Most ponds are stocked only once. Most farmers keep their ponds dry during July and August, and restock in September. As a result, the relatively high production costs forced farmers to optimize pond production by increasing stocking density to 25 to 35 juveniles per square meter for aerated ponds, and 15 to 25 juvenile per square meter for non-aerated ponds. To maintain acceptable biomass (< 400 grams per square meter), partial harvests are done when animals reach 16 grams, with final harvests at 47 to 50 grams. In 2000, aerated ponds averaged 4.66 metric tons (MT) per hectare per cycle and non-aerated ponds 3.45 MT hectare per cycle.

The strong seasonality also increases fixed costs for hatcheries and packing plants. Hatcheries had to improve their productivity to provide all seedstock during a short period, between September and January. The packing plant had to modify its design and organization to increase from 10 to 16 MT of processed shrimp daily. This situation forces close integration of the industry at all levels, and every month the farmers and the packing plant manager schedule harvests with a maximum of four harvests of 4 MT each.

Processing, marketing

The first packing plant, owned by SODACAL, was initially established at the farm in 1988. In 1994, it was bought by SOPAC and relocated to Nouméa. In 1995, considering the increase of production and harvest seasonality, the plant was reorganized and expanded to conform to the norms of the main importer countries and be able to process 16 MT per day.

Most production is packed head-on, frozen in brine, and marketed in France (574 MT), Japan (310 MT) and Australia (264 MT), and also locally. Development of shrimp farming has boosted the local market. During the early 1980s, New Caledonians consumed only a few hundred kilograms per year, mostly wild-caught, small P. merguiensis, but local demand has increased to over 490 MT per year.

Commercial strategy

Because of high production costs, New Caledonian shrimp products must be sold in top-quality markets. SOPAC markets all shrimp exports from New Caledonia, and has developed a strong commercial strategy that is profitable to farmers. SOPAC and the farmers have a list of specification defining all rearing and packing procedures, from the broodstock and seedstock production, to grow-out and harvest. This results in constant high quality and allows buyers to know the products well.

Quality certification

All industry members are involved in a process to obtain the internationally recognized “QUALICERT” label for quality products. Hatcheries must be certified for rearing procedures and sanitary conditions. Farms must comply with environmental rules, stock at no more than 40 juveniles per square meter, keep production at no more than 400 grams per square meter, and implement strictly defined harvest procedures and 30-day dry out of ponds between cycles.

Feed processors must be certified for types of ingredient, quality of raw materials, and sanitary conditions. Shrimp transporters are controlled from the sanitary condition of the trucks, the duration of the trip, and the temperature of the shrimp during transport. The packing plant complies with strict organoleptic controls and sanitary standards, and rejects non-conforming shrimp. An active quality-control team organized with the veterinarian authorities oversees the bacteriological controls.

Because of the industry’s importance to the local economy, the Economic Observatory of the Shrimp Farming Sector (OEFA) was established to provide technical and economic analysis of shrimp farming in the sector to improve results as much as possible. It is directed by a board that includes representatives of the North and South Provinces, the Direction of the Rural Economy, SOPAC, and the GFA under the Presidency of ERPA, a government agency that surveys the local economy. The GFA handles operational management of the OEFA. OEFA provides monthly reports with harvest results from the previous month, forecasts production, and analyses production costs.

Future development

Further industry development will continue in two ways. One is implementation of improved rearing technology, with IFREMER support in the areas of genetic improvement, immunology, pathology and others. The other is increased farming area. Several years ago IFREMER inventoried potential sites, and a current study will show an additional 1,000 ha could be developed, which could improve production to 5,000 MT in the next decade.

Conclusion

The New Caledonian shrimp aquaculture is a model of originality. Locally developed and implemented semi-intensive technology allows farmers to achieve very high yields in an environmentally friendly manner. The industry has integrated closely to produce top-quality export products well positioned in world markets. Further industry development could significantly increase production.

(Editor’s Note: This article was originally published in the October 2001 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Hervé Lucien-Brun

General Manager

Aquaculture Department

WORD France

Porte de l’Arenas, entrée A

455, Promenade des Anglais

F-06200 Nice, France

Related Posts

Health & Welfare

Blue shrimp quarantined in New Caledonia genetic variability program

To improve the sustainability of their breeding programs, shrimp producers in New Caledonia established a program with certified SPF blue shrimp.

Responsibility

Assessing culture potential of red emperor snapper in New Caledonia

The red emperor snapper, known as “pouatte” in New Caledonia, is valuable throughout its broad geographic range and a highly valued food fish locally. Declining wild catches and market demand have provided the incentive to carry out technical feasibility studies to determine its commercial aquaculture potential.

Health & Welfare

Genetic improvement of Pacific blue shrimp addresses Syndrome 93 in New Caledonia

Caused by the bacteria Vibrio penaeicida, Syndrome 93 is triggered by temperature drops during the passage of cold fronts in winter.

Aquafeeds

Mixed maturation diets improve shrimp broodstock performance

An optimal maturation diet is a crucial factor in the successful sexual maturation and reproduction of shrimp in breeding operations.