Systems scaling-up and ongoing research for commercial hatchery systems

Since 1987, sea bass fry production in French hatcheries has increased steadily, from 1 million to around 15 million fingerlings per year. At the same time, the average selling price, on a real time cost basis, has fallen by more than 60 percent, and now averages 0.4 Euro per fish.

The main reasons for the 15-fold production increase in the past decade are a steady improvement in feed composition, feeding procedures, and the use of water recirculation technology. Recirculation systems provide a rearing medium that is qualitatively constant and adjustable, showing only slight and slow variations, and resulting in better survival and growth rates. Moreover, in a recirculating system, heating energy savings required for the production of 1-gram fingerlings corresponds to approximately 50 percent of the production cost from a heated flow-through hatchery.

The adaptation of the recirculation technique to produce pre-grown fish (from several tenths to about a hundred grams) was carried out during the 1990s. Back then, an increasing number of French fish farmers that used sea cages needed to increase their production in order to meet the expanding market demand. Given the inherent difficulties in physically enlarging their rearing systems, they decided to increase the productivity of their existing facilities. This alternative was implemented on the French Mediterranean coast, to improve the productivity per unit volume by initially stocking cages with larger fish pre-grown in recirculating systems. Today, most of the French production of pre-grown fingerlings is exported, mainly to other European countries.

Development of recirculating on-growing systems

The on-growing phase in recirculating systems usually lasts several years without any seasonal or complete interruption of production. Fish are usually grown under high density within large production units. These features have several important consequences to the design and operation of the rearing system: (1) designing and managing large water treatment units to match water quality to fish tolerance levels; (2) fitting oxygen delivery systems to respond to rapid and large variations in oxygen demand; (3) controlling the levels of nitrate and other compounds (tea colored water) when the water renewal rate is low; and (4) processing waste water and solids to ensure the sustainability of the production.

Until now, fish farms using recirculating systems for Mediterranean fish or turbot on-growing have been economic failures. This might be explained either by faulty technical design of the production system, or by incorrect operation over the long-term (not stocked and managed at optimal production levels).

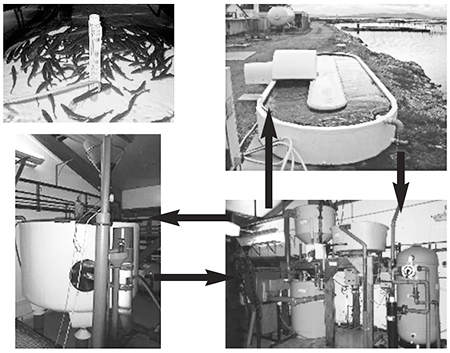

Promising results obtained in the late 1980s-early 1990s with experimental size units with a yearly production capacity of 2 to 5 tons per year (Fig. 1), encouraged the European Union to contribute to the development of industrial farms. This was done in 1996 by funding two pilot units designed to produce 50 to 70 tons of sea bass per year, one in southern France and the other in northern Iceland. Another pilot unit designed to produce 100 tons of turbot per year was built in 1999 in Brittany (France). These pilot systems have provided practical and theoretical knowledge on the design, management and cost of future commercial farms. In early 2000, the European Union (DG 13) accepted a new project aimed at building a full-scale industrial farm in Iceland, with an annual production target of 1,000 tons of sea bass in 1,200-cubic-meter units.

Final rearing system

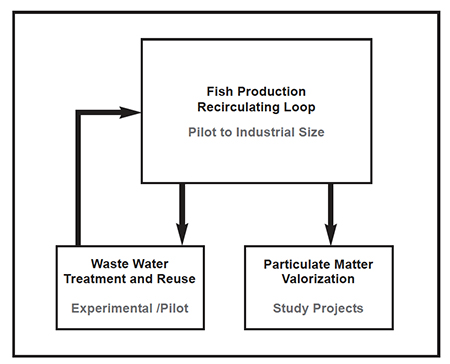

Fig. 2 shows the final system, which will include three main compartments:(1) fish production recirculating loop; (2) waste water treatment and reuse; and (3) waste particles treatment and valorization. Initial efforts were mainly focused on the fish production recirculation loop, and production costs are close to those from traditional rearing systems. This first step was successfully achieved, and industrial systems are now under construction. The system was optimized to provide environmental conditions fitting the requirements of sea bass, turbot or related species, while guaranteeing satisfactory profitability. The adaptation of this system to other fish species is ongoing, in order to better meet fish market demands. It also prevents escaping into the wild of genetically modified fish or non-indigenous species.

Although bacterial activity is of utmost importance in a recirculating system, very little is known about the bacteria that are present. For instance, in high-density, fish recirculating systems, bacteria and fish consume similar quantities of oxygen per kilogram of fish produced. The following steps will now focus on the wastes treatment and valorization. Current knowledge concerning (1) the bacterial populations associated to the fish rearing; and (2) the wastes treatment and valorization will be discussed in upcoming issues of this publication. Mastering the management of the three compartments will allow optimizing the reliability and profitability of the rearing system.

(Editor’s Note: This article was originally published in the June 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

-

D. Coves

IFREMER

Chemin de Maguelone, 34250

Palavas-les-Flots, France -

J.P Cailleres

2 Wedeco Katadyn France

BP 39, 77680

Roissy-en-Brie, France

Related Posts

Responsibility

Sea and brackish water recirculation systems for round and flat fish production, part 2

Recirculation systems not only limit environmental impact but can produce several species at once with minimal space requirements.

Responsibility

Airlifts combine pumping, water treatment in recirculation systems

Using the buoyancy of the entrained air bubbles to lift the water, airlifts are more energy-efficient and provide more aeration, carbon dioxide removal and foam fractionation for dissolved solids removal than centrifugal pump systems.

Responsibility

Automated temperature-controlled recirculation systems

A temperature-control system with a central chiller was found to enhance chilling and research capacity over a system with multiple unit chillers because replicating experiments in a single process control system minimized variations in the temperatures and chilling rates in the individual tanks. Temperature-holding experiments found slight differences at different temperature levels.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.