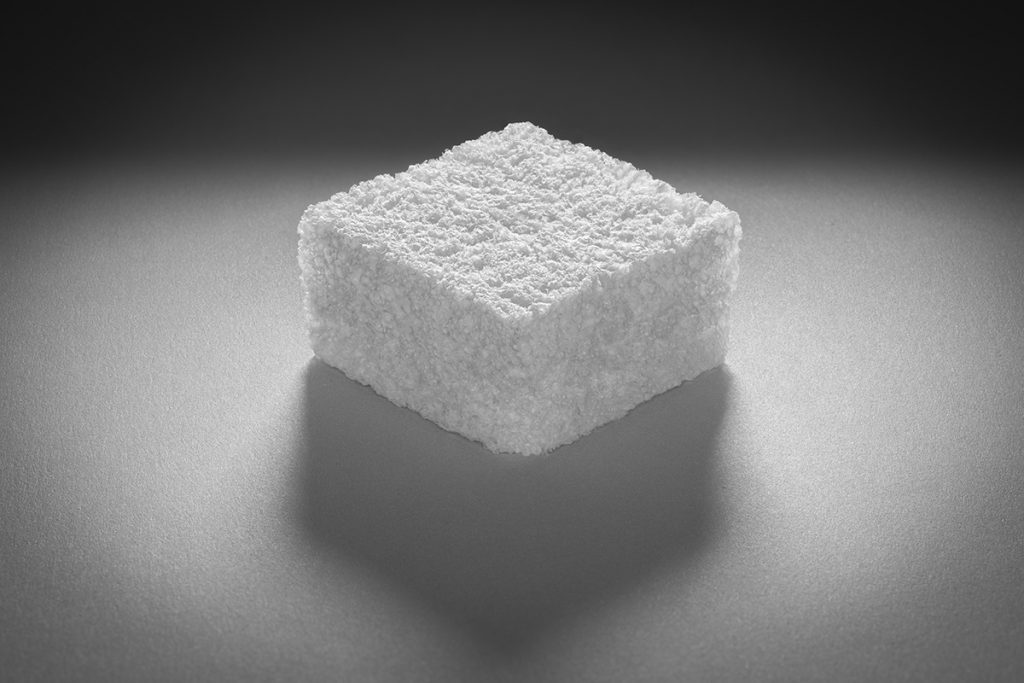

New bioplastic foam breaks down 15 times faster in seawater, offering possible solution to ocean pollution caused by plastic like Styrofoam

Scientists at the Woods Hole Oceanographic Institution (WHOI) have identified a new version of cellulose diacetate (CDA) – a bioplastic made from wood pulp – that degrades faster in seawater than any other bioplastic material they’ve tested, including paper.

By adding tiny pores, a process known as foaming, to the CDA structure, the material was found to break down 15 times faster than its solid form. The findings, published in ACS Sustainable Chemistry & Engineering, offer a promising alternative to traditional plastic foams, such as Styrofoam, which can linger in the environment for many years.

“What excites me most about this study is its translational nature,” said Collin Ward, senior author of the study. “This study is the culmination of years of research focusing on understanding the fundamental controls on CDA biodegradation in the ocean.”

The WHOI team partnered with scientists from the bioplastic manufacturing company Eastman, which provided funding, contributed as coauthors and supplied materials for the study.

“We translated the foundational knowledge into the design of a new material that simultaneously meets consumer needs and degrades in the ocean faster than any other plastic material we know of, even faster than paper,” said Ward. “It’s a great success story in a field that often focuses on the negative aspects of plastic pollution rather than working towards solutions to the problem.”

The study involved monitoring both foamed CDA and solid CDA in a tank of continuously flowing seawater from Martha’s Vineyard Sound at a specially designed lab at WHOI. The researchers also control the temperature, light exposure and other environmental variables to mimic the natural marine environment.

“Using continuous flowing seawater tanks enables us to bring the dynamics of the microbially active ocean into the lab,” said Bryan James, lead author and WHOI scientist. “The ocean is continually changing, and it was important that we replicated this environment by replenishing microbes and nutrients, making for a much more environmentally realistic experiment,”

After 36 weeks, the researchers observed that the CDA foam materials lost 65-70 percent of their original mass. In an earlier study, they tested straws made of regular plastic, paper, solid CDA and foamed CDA in seawater. They found that the solid CDA and paper straws broke down the fastest. When comparing two types of CDA straws – one solid and one foamed – the foamed version degraded 190 percent faster than the solid one, resulting in a shorter projected environmental lifetime than the paper straws.

“As a materials scientist and engineer, it’s been exciting to demonstrate that foams can be materially efficient, meaning they achieve functionality using the least amount of material possible, reducing cost and many environmental impacts,” said James. “In addition, when they are made from biodegradable plastics, they can be one of the least persistent forms of a material.”

The study highlights that replacing non-biodegradable plastics like Styrofoam and single-use containers, which often end up in the ocean, is a key use for foamed CDA. Foamed CDA products are already being introduced, with Eastman launching a compostable, lightweight tray to replace plastic trays in food packaging.

“The properties of foams make them ideally suited for many packaging and insulation applications, and this research shows that foams made of biodegradable materials will rapidly degrade in the marine environment, should they accidentally end up there,” said Jeff Carbeck, Vice President of Corporate Innovation of Eastman. “Advancing new plastics not made from fossil fuels, are compostable, and don’t persist in the environment as pollution, can be a win for consumers and the environment.”

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Responsible Seafood Advocate

[103,114,111,46,100,111,111,102,97,101,115,108,97,98,111,108,103,64,114,111,116,105,100,101]

Tagged With

Related Posts

Innovation & Investment

AKVA develops ocean net pens without polystyrene

Aquaculture equipment manufacturer AKVA Group says its new ocean net pens are free of polystyrene, a plastic foam common in consumer packaging.

Responsibility

Slow fish: Preventing waste via packaging

BluWrap shipping technology can cut the seafood industry's abysmal food-waste statistics by dramatically extending the shelf life of fresh product. Company CEO Mark Barnekow's mission is to get fresh fish off airplanes and onto ocean-bound cargo ships.

Responsibility

They’re ‘everywhere’: The pervasiveness of microplastics

How has the plastic in aquaculture operations contributed to microplastic pollution? And is plastic pollution contaminating aquaculture products? The Advocate takes a closer look.

Fisheries

‘Regulation is pushing toward greenifying materials’: How one innovator is upcycling seafood waste into biodegradable packaging foam

GOAL 22: Cruz Foam’s biodegradable packaging foam made with shrimp shells is a finalist for GSA’s inaugural Global Fisheries Innovation Award.

![Ad for [BSP]](https://www.globalseafood.org/wp-content/uploads/2025/07/BSP_B2B_2025_1050x125.jpg)