Huge plasma shrimp farm adopts biosecure modules

Established in 1987, P.T. Dipasena Citra Darmaja (DCD) developed a 16,250-hectare uninhabited swampland concession on the northeast coast of Lampung Province, South Sumatra, into an integrated shrimp farm with more than 18,000, 0.20-ha ponds. The farm operated under what is commonly known as the “plasma” profit-sharing system, where each qualified family runs two 0.20-ha ponds with management assistance from DCD. Under this team approach, the farmer is the plasma and DCD is the nucleus, supplying postlarvae, feed, and electricity, and buying back the shrimp produced by farmers.

In 1995, the company expanded and developed an adjacent concession of about 124,000 ha. More than 7,700 ponds of 0.25 to 1.80 ha were built for a total area of nearly 3,800 ha. A subsidiary company, P.T. Wachyuni Mandira, was allotted one-third of this area for plasma operation, and the remaining ponds were company assets.

Dipasena Citra Darmaja is well integrated with a power plant, hatchery, feed mill, processing plant, and cold storage, and marketing facilities that include container vessels. Its plasma farm was a massive undertaking in shrimp-farming history. In early 2006, new management took over to revitalize the farm.

Original farm design

The farm was originally designed and constructed based on single pond operators and a common canal management system. Ponds were arranged in rows with supply and discharge canals on opposite sides. The main effluent canals were built not only to discharge drainage waters from culture ponds, but also to be utilized as waterways for logistical management purposes by speed boats and barges. The water source was directly from the coast area, whereas the waste water was discharged into large upstream rivers adjacent to the farms.

Biosecurity

Production operations using canals and a single pond system for the production of black tiger shrimp (Penaeus monodon) were successful until the emergence of viral pathogens, especially White Spot Syndrome Virus in the mid-1990s. Most farms in shrimp-farming countries, including Indonesia, began to modify their operations to include reservoirs to treat culture water before use. However, the Dipasena farm kept using the single pond culture system, which led to low and unsustainable production levels.

One of the major undertakings of the new Dipasena farm management was a redesign of the existing rows of single ponds into a modular, biosecure culture system. A commercial module consists of 33 to 51 ponds reflecting 0.25 to 0.50 ha in two rows with its own reservoirs and quarantine and treatment ponds. The reservoirs’ water surface area is 20 percent of the culture pond area. The facility also transitioned to raising Pacific white shrimp (L. vannamei).

Module-based culture

Biosecure, module-based culture systems add water to shrimp ponds only after it has been isolated and treated. The Dipasena system has been redesigned with zero or minimal water exchange during culture cycles.

The modules are protected from air- and waterborne carriers by bird-scaring lines and crab fences around the module perimeters. In addition, a very strict biosecurity protocol is implemented from pond preparation through culture operations to harvest. No antibiotics or probiotics are used during pond preparation and culture operation periods.

Research trials

The function of research and development facilities located at both DCD and Wachyuni Mandira is to develop appropriate sustainable technology for the plasma ponds. The research facilities include nearly 200 ha of earthen ponds sized 0.045 to 2.000 ha with or without high-density polyethylene liners.

During the site conversion to the module-based system, trials begun in July 2006 were carried out in three of the completed, redesigned modules to determine a baseline, sustainable technology that was most appropriate to plasma culture ponds. The study examined energy input, stocking density, and pond performance correlated with locations, types, and sizes of culture ponds.

Performance results from grow-out trials that used specific pathogen-free postlarvae from the Dipasena group hatchery showed that the biosecure module design was effective in preventing viral diseases from being transmitted into the modules. Regardless of pond size and construction, the three modules were free of viral diseases. In contrast, nearby ponds using the original system had viral outbreaks affecting up to 40 percent of the ponds before reaching 45 days of culture. The biosecure modules’ common problems, such as power blackouts and human errors, were minimized through appropriate management.

Taw, Performance results in redesigned modular research ponds, Table 1

| Module 1 | Module 1 | Module 2 | Module 3 |

|---|

Module 1 | Module 1 | Module 2 | Module 3 | |

|---|---|---|---|---|

| Number of ponds | 2 | 6 | 24 | 20 |

| Pond size (ha) | 1.00 | 1.00 | 0.26 | 0.15-1.20 |

| Pond type | Lined | Semilined | Lined and unlined | Lined |

| Number of aerators | 30 | 16 | 2-8 | 2-32 |

| Stocking density (shrimp/m2) | 159 | 79 | 60-131 | 73-155 |

| Days of culture | 110 | 126 | 118-124 | 118-139 |

| Survival (%) | 66.9 | 78.8 | 72.3-92.3 | 65.8-84.8 |

| Mean body weight (g) | 13.6 | 13.8 | 14.0-15.3 | 12.5-15.6 |

| Feed-conversion rate | 1.59 | 1.69 | 1.58-1.90 | 1.55-2.34 |

| Average daily growth (g) | 0.12 | 0.11 | 0.11-0.13 | 0.09-0.13 |

| Production (mt shrimp/ha) | 14.46 | 8.72 | 8.30-14.88 | 8.27-13.37 |

| Production/power input (kg/hp) | 482 | 545 | 484-1,080 | 291-626 |

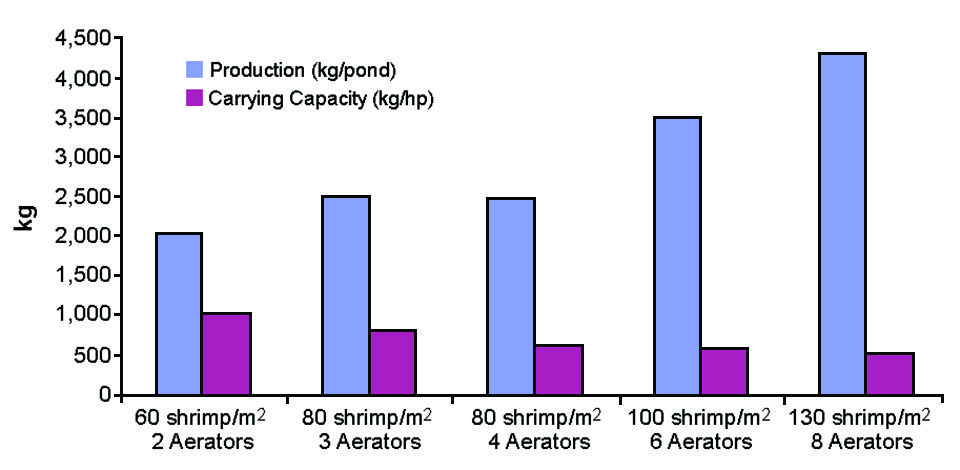

In general, production of 10 metric tons (MT)/ha was achieved from lined ponds during trials (Table 1). This was similar to the yields of 430 to 631 kg/hp for 0.50-ha, lined ponds reported in 2004 by the author. However, for the 0.26-ha ponds similar to plasma ponds, an exceptionally high carrying capacity of 1,080 kg/hp was achieved, with a record production of 4,320 kg with 82.6 percent survival (Fig. 1).

A very important result for marketing purposes was the red color of harvested shrimp after cooking. More than 60 percent of the shrimp harvested were above 25 in the SalmoFan scale.

Commercial trials

Commercial trials in Wachyuni Mandira biosecure modules were started two months after the research trials were initiated. Seven modules that began operations within a period of two weeks were operated under the supervision of research technicians. To date, three modules have been successfully harvested. Based on sampling data, the performance of the remaining modules was expected to be similar to that of the harvested modules.

Taw, Performance results in commercial modular ponds, Table 2

| Module 1 | Module 2 | Module 3 |

|---|

Module 1 | Module 2 | Module 3 | |

|---|---|---|---|

| Number of ponds | 51 | 51 | 33 |

| Pond size (ha) | 0.25 | 0.25 | 0.50 |

| Pond type | Lined | Lined | Lined |

| Number of aerators | 4 | 4 | 8 |

| Stocking density (shrimp/m2) | 86 | 83 | 83 |

| Days of culture | 118 | 117 | 118 |

| Survival (%) | 74.7 | 81.2 | 79.2 |

| Mean body weight (g) | 14.6 | 15.0 | 15.4 |

| Feed-conversion rate | 1.61 | 1.65 | 1.73 |

| Average daily growth (g) | 0.12 | 0.13 | 0.13 |

| Production (mt shrimp/ha) | 9.12 | 10.15 | 10.07 |

Table 2 shows performance data from the ponds already harvested. The production modules averaged 9.12 to 10.15 MT shrimp/ha with 16 hp/ha used in the 0.25- and 0.50-ha lined ponds. These results were consistent with those from the earlier research trials.

(Editor’s Note: This article was originally published in the May/June 2007 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Nyan Taw, Ph.D.

P.T. Dipasena Citra Darmaja

Exim Melati Building, 10th Floor

J1 M. H. Thamrin Kav. 8-9

Jakarta 10230 Indonesia -

Cyrus R. Regalado

P.T. Dipasena Citra Darmaja

Exim Melati Building, 10th Floor

J1 M. H. Thamrin Kav. 8-9

Jakarta 10230 Indonesia -

Wartono

P.T. Dipasena Citra Darmaja

Exim Melati Building, 10th Floor

J1 M. H. Thamrin Kav. 8-9

Jakarta 10230 Indonesia -

Yohanes Slamet

P.T. Dipasena Citra Darmaja

Exim Melati Building, 10th Floor

J1 M. H. Thamrin Kav. 8-9

Jakarta 10230 Indonesia -

Pangesti Tomo

P.T. Dipasena Citra Darmaja

Exim Melati Building, 10th Floor

J1 M. H. Thamrin Kav. 8-9

Jakarta 10230 Indonesia

Related Posts

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Health & Welfare

Recent developments in biofloc technology

Combining biofloc technology with bio-secure modular shrimp culture can make operations more sustainable and economically viable. For optimized biofloc production, lined ponds and reservoirs and high stocking densities are essential. Paddlewheel aerators keep dissolved-oxygen levels high.

Aquafeeds

A look at phospholipids in aquafeeds

Phospholipids are the major constituents of cell membranes and are vital to the normal function of every cell and organ. The inclusion of phospholipids in aquafeeds ensures increased growth, better survival and stress resistance, and prevention of skeletal deformities of larval and juvenile stages of fish and shellfish species.

Aquafeeds

Animal byproduct concentrates useful tools in formulation

With the market volatility of fishmeal, as well as rising sustainability concerns, the aquaculture industry is seeking sources of protein, such as animal byproduct concentrates, to substitute for fishmeal.