Paddlewheel aerators have been used for decades

Aeration of aquaculture ponds, especially intensive ponds, is an essential requirement. Proper aeration is needed to obtain expected production, while on the other hand, it is an appreciable component of production cost.

An adequate aeration system should fill several roles while minimizing energy consumption. Aeration must supply enough oxygen to overcome oxygen limitations and enable high stocking and production levels. It must distribute the oxygen in the pond, both horizontally and vertically, and mix the water at the water-sediment interface. Proper aeration also minimizes sludge piles on pond bottoms and eases pond drainage.

Reviewing the technical publications as well as field practice, one may be astonished by the fact that essentially the same aerators have been used for decades. During this period, aquaculture production rose dramatically, feeds were greatly improved, and new species were cultured. Is this because the present aerators are so good?

Oxygen stratification

One of the major factors affecting aeration efficiency is the development of thermal and oxygen stratification in aquaculture ponds. Thermal solar radiation is adsorbed by the superficial water layers, raising the temperature and forming a stable warm and light water layer. Moreover, algae photosynthesis and oxygen release preferentially take place in this superficial layer. Thus, during daytime – and often in the early nighttime – the top layer of pond water is relatively enriched with respect to oxygen, while the bottom layer and the water-sediment interface have limited oxygen.

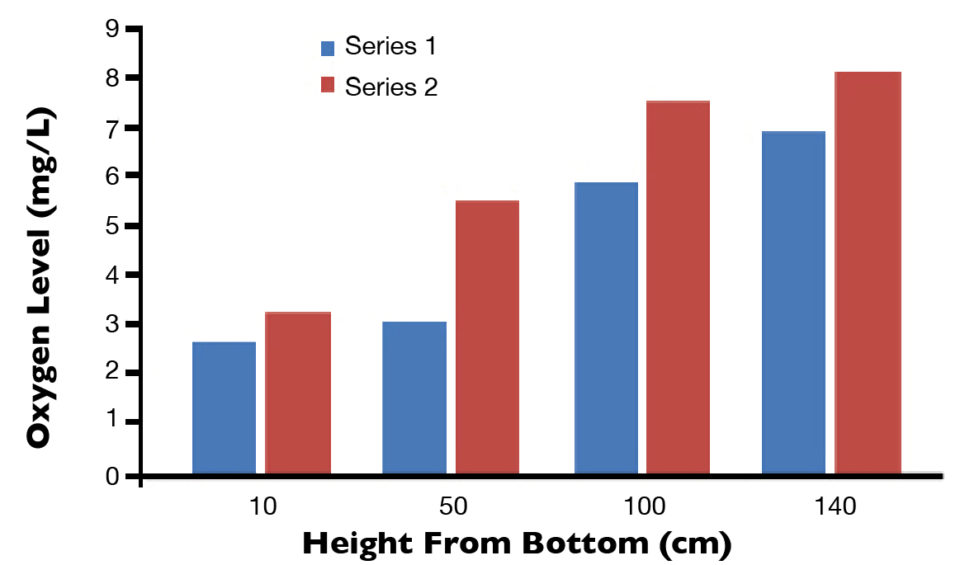

As an example, oxygen profiles in a commercial shrimp pond are shown in Fig. 1. They were monitored across the pond at about 11 a.m. on a sunny day, when oxygen supply was likely to be optimal. At 6 to 8 mg/L, the oxygen concentrations in the surface layers were very high – in fact, super-saturated. However, at about 10 cm above the pond bottom, oxygen concentrations were very low, in the range of 2 to 3 mg/L. Oxygen is practically zero in the soil-water interface. It is important to mention that the bottom water layer is the zone where shrimp live and harvest feed and natural food.

This typical oxygen stratification is an important limitation in pond productivity, not only due to oxygen limitation for shrimp and fish in the bottom pond water, but also due to the development of anaerobic conditions in the sediment-water interface. To minimize this, one has to maximize mixing of this layer and direct the accumulated organic sludge toward the pond’s drainage outlet.

Paddlewheel aerators

Paddlewheel aerators of different kinds are the most commonly used aerators. With these designs, aeration is achieved by splashing water in the top 20 cm of the water. As mentioned, this layer is the richest with respect to oxygen concentrations.

The efficiency of aerating oxygen-rich surface water is very low when compared to the possible aeration of the oxygen-poor bottom water. Assuming a freshwater pond in which the oxygen concentration in the surface water is 5 mg/L and that of the bottom water is 2 mg/L, the aeration efficiency (as calculated following Dr. Claude Boyd’s 1998 method for defining standard aeration efficiency) for the surface water will be about 45 percent of standard and 70 percent for aerating the bottom water. An aeration device that aerates the bottom water will be much more efficient, supplying almost twice as much oxygen for the same power consumption.

In addition to their low aeration efficiency, paddlewheel aerators deliver oxygenated water to the surface layer, while oxygen is badly needed by the bottom water layers. Paddlewheel aerators do a poor job with respect to vertical water mixing. The paddlewheels provide momentum to the water, pushing it horizontally across the pond. Yet, this momentum is given to the surface water and only partially used to move and mix the bottom water layers.

To raise aeration efficiency and aerate the bottom water, a different approach is required. A simple suggestion made by Dr. John Colt was to modify the paddlewheel aerator to a skirted paddlewheel design. By inserting a plastic or metal sheet barrier on the upstream side of a paddlewheel, the water would be pulled from the bottom.

Vertical mixing

Some commercially available aerators are designed to provide vertical mixing by pulling water from deeper layers. However, the oxidized water is released at the surface of the pond. Aspirators apply the oxygen to water of the topmost water layers, yet have the advantage of sending the aerated water jet downward. However, the effect of the jet is limited to only a portion of the pond bottom.

Diffused-air systems as such do not have efficient mixing potential and, unless placed in deep parts of the pond, loose efficiency due to the rapid rise of the diffused bubbles. It seems possible to use airlift technology to improve aeration systems.

Airlift enhancement

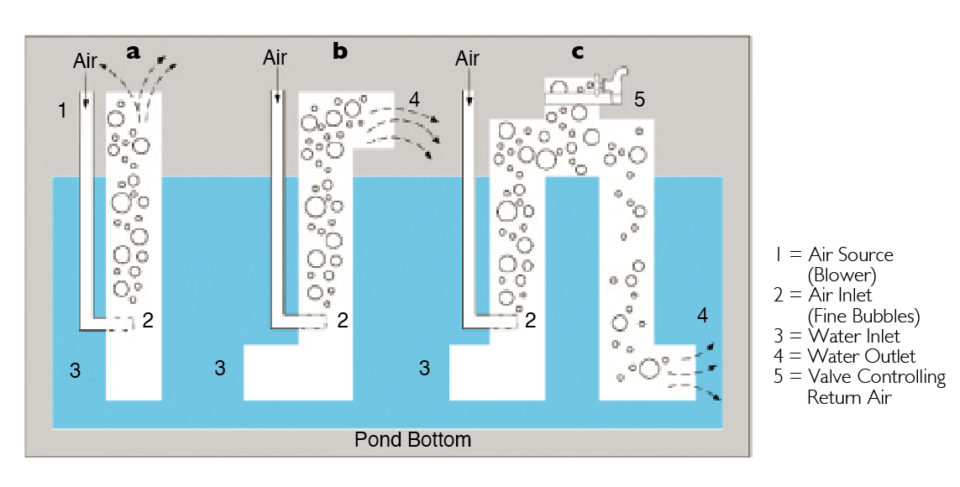

Airlifts are made by injecting air bubbles into tubes inserted in the water. The bulk density of the water with air bubbles inclusion is lower than that of the pond water, thus water outside flows into the lift and pumps the water upward (Fig. 2a). The airlift unit pumps water from the pond bottom, an important advantage. If 90-degree inlet and outlet tubes are utilized, the same unit induces horizontal water movement in both bottom and surface layers (Fig. 2b). These units can be very useful in aerating and mixing relatively small intensive tanks.

In 2012, William Wurts suggested the use of modified airlift units that include an attached blower for commercial-scale ponds. The airlift design may be further developed, so as to pump water from the bottom layer, release the aerated water into the bottom layer and generate a horizontal flow at the bottom of the pond (Fig. 2c).

The unit is made of an intake arm, roughly an ordinary airlift. A controlled air valve is placed in the horizontal part, and an outlet arm follows. The air valve releases part of the rising air bubbles, and thus, the water in the outlet arm is heavier than that in the inlet arm. If the air release valve is fully open and releases most of the air bubbles, water flow through the system is maximal. On the other hand, with limited release, the flow is lowered, but the downward-moving bubbles further release oxygen to the water.

The unit can effectively act as a double-length airlift that almost doubles the oxygen uptake efficiency. The system has a number of advantages: It aerates the oxygen-poor water close to the pond bottom, releases the oxygenated water to the pond bottom and induces water flow that mixes the pond bottom stratum. It also does not have any corrodible components in the water.

Water circulators, used often to destratify lakes, are equivalent to the fans we often use at home. These units move water using a very low hydraulic head, thus consuming very little energy to move large volumes of water across the pond.

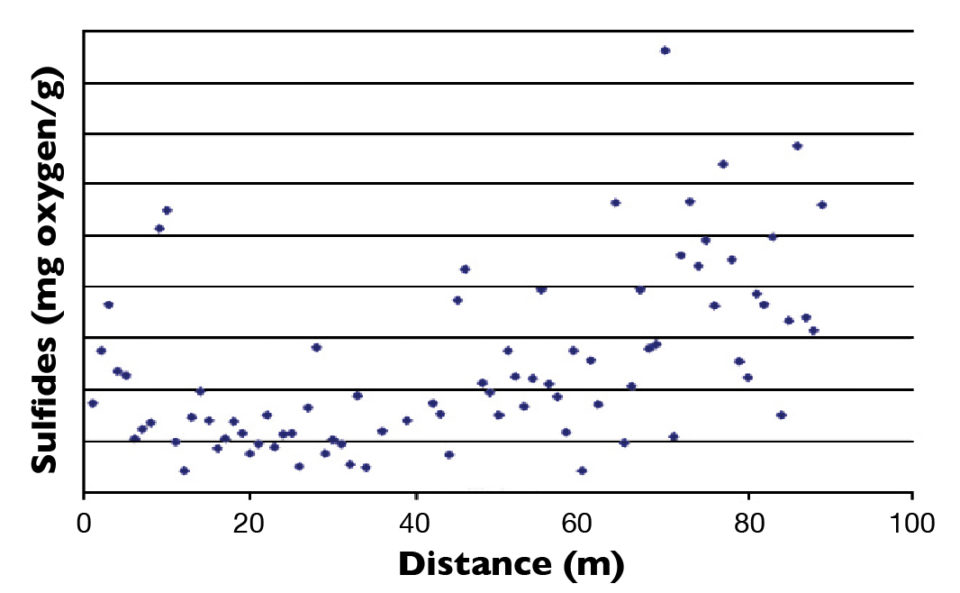

Fig. 3 shows the effects of a 2.5-hp circulator on redox indicators in the bottom of a highly stocked tilapia pond. Sulfides, indicating the dominance of anaerobic conditions, are very low in most samples up to 60 m downstream from the circulator.

Perspectives

Aerators, especially paddlewheels, are often used to mix the water and address oxygen stratification in ponds. These units consume energy to splash surface water up in the air, which is often accompanied by the loss of oxygen from the top layer of over-saturated water.

Presently, most aerators do not provide the most efficient and power-conscious service. Mixing of water can be done in a more efficient way by using the modified airlifts described above or employing water circulation units.

(Editor’s Note: This article was originally published in the July/August 2015 print edition of the Global Aquaculture Advocate.)

Author

-

Yoram Avnimelech, Ph.D.

Civil and Environmental Engineering

Technion – Israel Institute of Technology

Technion City, Haifa 3200003, Israel

Tagged With

Related Posts

Responsibility

Efficiency of mechanical aeration

Although relatively expensive, mechanical aeration increases production. Asian-style paddlewheel aerators are widely used but are inefficient. Testing has led to more efficient designs that are now widely used in U.S. catfish and shrimp ponds.

Health & Welfare

Proper water circulation in aquaculture ponds critical

Promoting water circulation during the day time is an effective strategy to enrich pond water with oxygen produced by photosynthesis, and can significantly reduce the costs of night time supplemental aeration.

Health & Welfare

Advice for managing predatory birds, part 1

Predatory birds can cause major losses for tilapia farms. As some bird species are protected by law, fish farmers must use non-lethal control techniques.

Responsibility

Does Coriolis force impact aerator placement in aquaculture ponds?

The Coriolis effect has no bearing on aerator placement and aquaculture pond management. The most important consideration with mechanical aeration is to provide a sufficient amount to maintain adequate dissolved oxygen concentration.