GAA’s George Chamberlain summarizes common, proven techniques

In semi-intenstive and intensive pond culture, shrimp are typically harvested by completely draining ponds and capturing the animals as they exit with the water. However, partial harvesting is sometimes an important alternative that can be used to “thin” the biomass or supply small quantities of shrimp to local markets.

In semi-intenstive and intensive pond culture, shrimp are typically harvested by completely draining ponds and capturing the animals as they exit with the water. However, partial harvesting is sometimes an important alternative that can be used to “thin” the biomass or supply small quantities of shrimp to local markets.

Partial harvesting can be accomplished by draining, cast or lift netting, seining, or trapping. After harvest, the shrimp are usually loaded into bins with ice at pond side.

Drain harvesting

Draining is not the most effective means of partial harvesting, because most of the shrimp remain in the pond until it is almost empty. Often, it is impractical to partially drain harvest large ponds. Water replacement represents a significant pumping cost and, in some areas, a biosecurity risk. Also, the shrimp retained in the pond can be stressed by poor water quality due to the higher water temperature and resuspended, anoxic sediments that result during the final stage of harvest. If the shrimp are exposed to low water levels during the day, they can suffer increased bird predation. The introduction of replacement water also changes water quality, which can be stressful.

Cast netting

Cast netting is a simple, but relatively inefficient partial harvesting technique that was commonly used in the early years of shrimp farming. Catch efficiency is improved by attracting shrimp to an area of the pond using natural foods or dry feed, but labor costs limit the use of cast netting in most countries.

Seine harvesting

The efficiency of seining varies with the behavior of the particular shrimp species and the size and construction of ponds. Conventional seines tend to pass over deep-burrowing species such as Penaeus japonicus and, to a lesser extent, P. monodon.

Water jet, electrical seines

During the 1960s, Japanese shrimp farmers developed a beam net mounted to a sled with nozzles that jetted water into the pond bottom. The jets stimulated the deep-burrowing P. japonicus to jump as the net passed by. This system was later modified by using a weak electric current, rather than water jets, to stimulate the shrimp.

The electric current was created by connecting insulated cathode and anode wires from a floating automobile battery. When the wires reached a 3.5-meter horizontal bamboo pole used to spread and pull the net, the cathode and anode wires split and extended to opposite ends of the net.

At the point where the wires extended downward along the sides of the net and inward toward the middle of the lead line, the insulation was removed to create a U-shaped current. A voltage regulator attached to the battery adjusted the current in the range of 8-12 volts, depending on shrimp activity and temperature.

Large seines

P. vannamei are less prone to deep burrowing. Consequently, standard seining can be used, provided that ponds are no deeper than 1 meter and bottom contours are even and clear of tree stumps and roots.

Shrimp have an uncanny ability to move around or under seines, so the typical procedure is to use a seine large enough to traverse the entire width of a pond. To determine the size of net required, assume that for every 2 meters of pond width to be seined, 3 meters of seine length is required. The same ratio applies to pond depth.

The seine can be pulled by a tractor, but care should be taken not to pull too fast and cause the lead line to lift off the bottom. To avoid dredging up too much bottom mud as the seine is pulled across the pond, the standard lead-weighted line can be replaced with a mud line. A mud line consists of many strands of rope or a roll of netting bound together.

Seining across the entire pond width becomes more difficult to manage with larger ponds. Mud and detritus is often mixed with the shrimp, and excess shrimp may not survive, if released. To better control the quantity and quality of harvested shrimp, individual seines can be used.

Individual seines

In the northwestern Mexico state of Sonora, the growing season is only seven to eight months long. Given the current low prices for small shrimp, it is more profitable to produce a single crop of large shrimp than two crops of small shrimp.

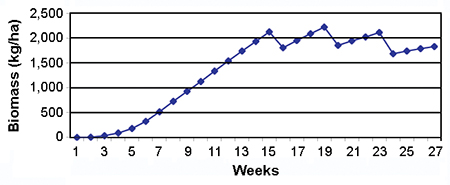

A common technique is to stock semi-intensive ponds with a relatively high density of 20 to 25 per square meter and thin the crop when the biomass approaches 2 to 2.5 metric tons (MT) per hectare. If the standing crop reaches this biomass after the first partial harvest, a second or even third partial harvest could be conducted Table 1, Fig. 1). The remaining shrimp continue to grow to sizes of 30 to 32 grams at harvest. Final harvest fluctuates around 1.2 to 1.8 MT per hectare of large shrimp.

Chamberlain, Typical production parameters, Table 1

| Typical Values | Shrimp Size |

|---|

Typical Values | Shrimp Size | |

|---|---|---|

| Stocking density (PL/m2) | 20.0 | |

| Survival (%) | 70% | |

| First partial harvest (kg/ha) (g) | 50 | 14.3 |

| Second partial harvest (kg/ha) (g) | 498 | 19.9 |

| Third partial harvest (kg/ha) (g) | 510 | 25.5 |

| Final harvest (kg/ha) (g) | 1,866 | 31.1 |

| Total production (kg/ha) | 3,374 | |

| Average growth (g/week) | 1.11 | |

| Feed-conversion ratio | 1.94 | |

| Days of culture | 196 |

Efficient individual seines, locally called “churupas,” are used to partially harvest these ponds using a design developed by local fishermen for use in shallow bays. It consists of an 8-meter-long x 1.5-meter-deep mono-filament net shaped like two connected cones. The bottom border of the net is connected to the lead line, which is tied to the ends of a 3.5-meter horizontal pole. A lighter lead line is attached to the top edge of the net to cause it to drape into the water column, but not all the way to the bottom. This leading veil of netting prevents shrimp from escaping out the front of the net.

The upper edges of the two net cones are connected by cord to the horizontal pole. As the seiner walks the length of the pond pushing the horizontal pole ahead of him and dragging the net behind, shrimp accumulate in the two cones sewn into the netting. In a typical drag of semi-intensive ponds in Sonora, each seine captured an average of 60 kg during each 30-minute drag.

Lift nets

Lift nets take advantage of the behavior of shrimp to concentrate in areas where feed is administered. The process involves positioning a net on the bottom of the pond, distributing feed, waiting a few minutes and lifting the net to capture the shrimp. This is a convenient and extremely gentle harvesting process that works well for Malaysian farms that harvest shrimp for the live market in Singapore.

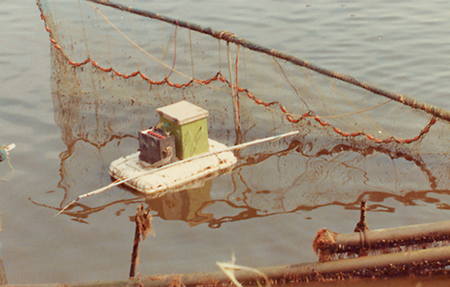

A typical arrangement consists of a 20- to 36-mm-mesh net with dimensions of 10-by-10 meters and lead lines attached to all four sides. The corners of the net connect to pulleys tied about 3.5 meters above water level on four poles positioned about 7 meters apart.

Lift nets are normally used at night, when shrimp tend to swim about more freely. Feeding should be stopped several hours before harvest. The process involves the following steps: turning off the aerators near the trap, lowering the net to the bottom of the pond, distributing a few handfuls of feed directly above the netted area, waiting about 3 to 10 minutes, and pulling up the net using the ropes attached to the corners. The captured P. monodon are weighed and placed in aerated tanks for hauling to the live market.

Catch rates depend upon the stocking density and pond size. Small ponds tend to yield more per lift than big ponds. A typical catch is 10 to 50 kilograms per lift, and lifts can be repeated every 10 to 20 minutes. Catches diminish over time. On the first and second night of lift netting, the catch might range 500 to 1,000 kg. This typically diminishes to about 300 to 600 kg by the fourth and fifth night.

If the lift net is used for several successive days in the same pond, it can cause reduction of growth rates and a higher percentage of soft-shelled animals. This is thought to be related to fouling of the bottom in the area near the net and a general lowering of the dissolved oxygen level.

Trap nets

Trap nets take advantage of the behavior of P. monodon to swim around the edges of ponds. A section of netting diverts the swimming shrimp from the edge into the trap net, where they collect. This system has been used in Australia to gradually harvest ponds over six to eight weeks to sell high-quality cooked shrimp to the Sydney seafood market.

Trap nets are set up in ponds for the duration of each day’s harvest. It only takes about four minutes to deploy each net, which is held in place by a metal picket at each end. The nets do not damage the shrimp and collect no mud. They also serve to grade the shrimp, because small shrimp can pass through the net. Removal of shrimp from the nets requires two people in each pond plus one handling the jib crane on shore. Each of these trap nets can collect up to 400 kg of prawns per net per hour.

As the shrimp thin out over the extended harvesting period, more nets are deployed. Over the duration of the harvest, feed application is reduced as prawn biomass is harvested. Eventually, feeding ceases when prawn biomass reaches less than about 750 kilograms per hectare. The nets can remove about 99 percent of the shrimp from the ponds.

This method has an environmental advantage over ponds that are drain harvested immediately following a period of maximum feed input. With the trap nets, pond water is held for an extended period during which nutrient inputs are gradually reduced to nothing. In this way, the water eventually drained from the pond after the harvest has been “stabilized” after very low or no nutrient input for a month or longer.

Conclusion

Partial harvesting can be a useful tool to thin the density of shrimp or to harvest small quantities of shrimp for local markets. A variety of techniques can be used, depending on the species of shrimp, size and condition of ponds, and the intended purpose.

(Editor’s Note: This article was originally published in the August 2002 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

-

Adam Body

ARDA-TEK

Winnellie, Northern Territories

Australia -

Randall Aungst

Black Tiger Aquaculture Sdn. Bhd.

Endau, Pahang, Malaysia -

Marcelo Costero

Vimifos/Zeigler

Ciudad Obregon, Mexico -

Bernardo de la Mora

Vimifos/Zeigler

Ciudad Obregon, Mexico

Tagged With

Related Posts

Responsibility

Aquaponic system produces red drum, saltwater vegetable species

A project in Florida is studying the feasibility of a marine aquaponic system containing red drum and two native saltwater species. Water that exits the plant raceways is filtered and recirculated to the fish tanks. In tests, sea purslane grew rapidly, while saltwort took almost four months to adapt. The fish exhibited high survival and achieved a feed-conversion ratio of 1.2.

Responsibility

Bangladesh study examines potential for prawn cage farming

While Bangladesh's prawn industry is based on pond culture, a feasibility study was conducted to establish prawn cage culture to benefit resource-poor fishers and landless people.

Health & Welfare

Biofloc technology expanding at white shrimp farms

Biofloc technology provides high productivity, low feed-conversion ratios and a stable culture environment. Also, with viral problems and rising costs for energy, biofloc technology can help deliver sustainable production at lower cost.

Health & Welfare

Biofloc technology: Possible prevention for shrimp diseases

Facing emerging viral problems and rising energy costs, the use of biofloc technology in biosecure systems offers an answer for sustainable shrimp aquaculture. The main attributes of biofloc systems in reducing disease risk include the fact that low water exchange improves pathogen exclusion.