Nitrification consumes oxygen, is a source of acidity

Nitrification is a natural water purification process by which certain bacteria oxidize and transform potentially toxic ammonia to nontoxic nitrate. This process is especially important in aquaculture ponds and water reuse systems, where ammonia can reach concentrations harmful to fish and shrimp.

Nitrification process

Nitrification is a two-step process by which bacteria of the genus Nitrosomonas oxidize ammonia or ammonium to nitrite, and bacteria of the genus Nitrobacter oxidize nitrite to nitrate. Because Nitrosomonas and Nitrobacter occur together, nitrite is normally oxidized as soon as it appears. However, for reasons not well understood, nitrite sometimes accumulates in aquaculture systems.

When nitrite is absorbed by fish and other aquatic organisms, it can combine with hemoglobin to cause methemoglobina or nitrite toxicity – often known as Brown Blood Disease. It also is noteworthy that nitrification consumes oxygen and is a source of acidity because it releases hydrogen ions.

Nitrifiers use a small portion of the energy released when ammonia is oxidized to nitrate to reduce inorganic carbon in carbon dioxide to organic carbon. Nitrifiers are among a group of organisms known as chemoautotrophic bacteria that can synthesize organic matter by a nonphotosynthetic process.

Ammonia sources

Fertilizers and aquafeeds are sources of ammonia in aquaculture systems. Typical percentages of nitrogen in ammonium fertilizers are given in Table 1. Some may not recognize urea as an ammonium fertilizer, but when it is placed in water, urea quickly hydrolyzes to ammonia and carbon dioxide.

Fertilizers are applied to ponds in relatively small amounts and normally do not raise ammonia concentrations to toxic levels. Ammonium from fertilizers is absorbed by phytoplankton and converted to organic nitrogen in protein. When phytoplankton die, they decompose and release ammonia.

A small proportion of fertilizer nitrogen also can become organic nitrogen in fish or shrimp biomass via the food web. Nevertheless, much of the ammonia added to ponds in fertilizers is nitrified. Nitrification does not detract from the benefit of fertilization, for nitrate is a nitrogen source for phytoplankton and other plants.

Feed, nitrogen waste

Fish and shrimp usually eat most of the feed offered to them. A large proportion of the consumed feed is absorbed across the animals’ intestines and incorporated into animal biomass, and the rest is expelled as feces. Uneaten feed and feces decompose and release carbon dioxide, ammonia, and other inorganic nutrients. All nitrogen applied in feed and not harvested in biomass can potentially reach the water as ammonia.

Aquafeeds range in crude protein concentration from less than 25 percent to more than 40 percent, and fish and shrimp typically contain 14-18 percent crude protein. Nitrogen and crude protein in feed and fish can be related by the following equation.

% Crude Protein = % Nitrogen x 6.25

Consider the production of 1,000 kg fish with 15 percent crude protein (2.40 percent nitrogen) in a 2,000-cubic-meter pond using 2,000 kg feed with 32.00 percent crude protein (5.12 percent nitrogen). The nitrogen input would be 102.4 kg (2,000 kg feed x 0.0512), and 24.0 kg nitrogen would be removed in fish (1,000 kg fish x 0.024). Thus, up to 78.4 kg nitrogen (102.4 kg nitrogen in feed – 24.0 kg nitrogen in fish) could enter the water in ammonia. This example showing 23.40 percent of feed nitrogen recovered in biomass is fairly typical, but up to 40.00 percent recovery can be achieved.

If all of the potential nitrogenous wastes resulting from 2,000 kg feed accumulated in a 2,000-cubic-meter pond, the total ammonia nitrogen concentration would reach 39.2 mg per liter. Depending upon species and water pH and temperature, total ammonia nitrogen concentrations of 2.0 to 10.0 mg per liter can be toxic. Fortunately, nitrification and other natural processes such as ammonia volatilization, uptake by microorganisms, and loss in outflow usually prevent ammonia concentration from accumulating to its maximum potential.

Nitrification and acidity

Nitrate is not toxic, but nitrification consumes dissolved oxygen and can be a major source of acidity to neutralize alkalinity. Nitrification can contribute 30-40 percent of the oxygen demand.

Fertilizer manufacturers report the acidity of ammonium fertilizers as calcium carbonate necessary for its neutralization (Table 1). A typical application rate for urea in ponds is 50-100 kg/ha/crop. These rates could produce acidity equal to 80.5-160.0 kg calcium carbonate/ha/crop. This amount of acidity can be a serious problem in water with total alkalinity concentrations below 20 mg per liter. Periodic liming is necessary to avoid low alkalinity in some fertilized ponds.

Boyd, Nitrogen concentration, Table 1

| Fertilizer | Nitrogen (%) | Potential Acidity (kg calcium carbonate/ 100 kg fertilizer) |

|---|

Fertilizer | Nitrogen (%) | Potential Acidity (kg calcium carbonate/ 100 kg fertilizer) |

|---|---|---|

| Urea | 45 | 161 |

| Ammonium nitrate | 34 | 118 |

| Ammonium sulfate | 20 | 151 |

| Diammonium phosphate | 18 | 97 |

| Ammonium polyphosphate | 13 | 72 |

| Monoammonium phosphate | 11 | 79 |

Calcium carbonate treatment

Nitrogen inputs to ponds in feeds usually are much higher than fertilizer nitrogen applications. The amount of calcium carbonate required to neutralize the potential acidity of feed can be calculated using the following equation.

Calcium Carbonate Equivalence of Feed (kg) = Feed Input (kg) x % Crude Protein in Feed x 0.01285

In a pond producing 5,000 kg shrimp/ha/crop using feed with 35 percent crude protein and achieving a feed-conversion ratio of 2.0, the calcium carbonate equivalence of the feed would be 4,498 kg/ha. In a water-reuse system receiving 1,000 kg/day of feed containing 30 percent crude protein, the calcium carbonate equivalence would be 385 kg/ha/day. In intensive systems, especially water-reuse systems, nitrification can cause alkalinity and pH to decline rapidly. Frequent use of liming materials may be necessary.

Nitrification is a natural process and nitrifying bacteria are ubiquitous. It is not necessary to add nitrifiers to aquaculture systems, but initiation of nitrification in closed systems, especially marine ones, can be accelerated by seeding with nitrifiers. Several companies sell cultures of nitrifying bacteria for such applications.

Nitrification can occur at low pH, but it proceeds best at a pH near 8. Thus, regular application of liming materials often is necessary to maintain effective nitrification. Low dissolved-oxygen concentration also is associated with low rates of nitrification. Ponds with chronically low dissolved oxygen during nighttime often have higher ammonia concentrations than ponds with higher nighttime dissolved-oxygen concentrations. Adequate mechanical aeration is needed to nsure effective nitrification.

Nitrite toxicity

In freshwater systems, nitrite toxicity can be counteracted by applying sodium chloride to elevate the chloride concentration. Chloride blocks the uptake of nitrite across the gills of fish and other aquatic animals. A 20:1 ratio of chloride to nitrite usually prevents nitrite toxicity. Nitrite is less problematic in brackish water and marine systems.

Intensive, heterotrophic aquaculture systems contain dense bacterial flocs instead of heavy phytoplankton blooms. These systems do not have extremely high ammonia concentrations. Ammonia is removed from the water and incorporated into microbial biomass, but high nitrification rates also occur.

(Editor’s Note: This article was originally published in the May/June 2007 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Claude E. Boyd, Ph.D.

Department of Fisheries and Allied Aquacultures

Auburn University

Alabama 36849 USA

Tagged With

Related Posts

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Innovation & Investment

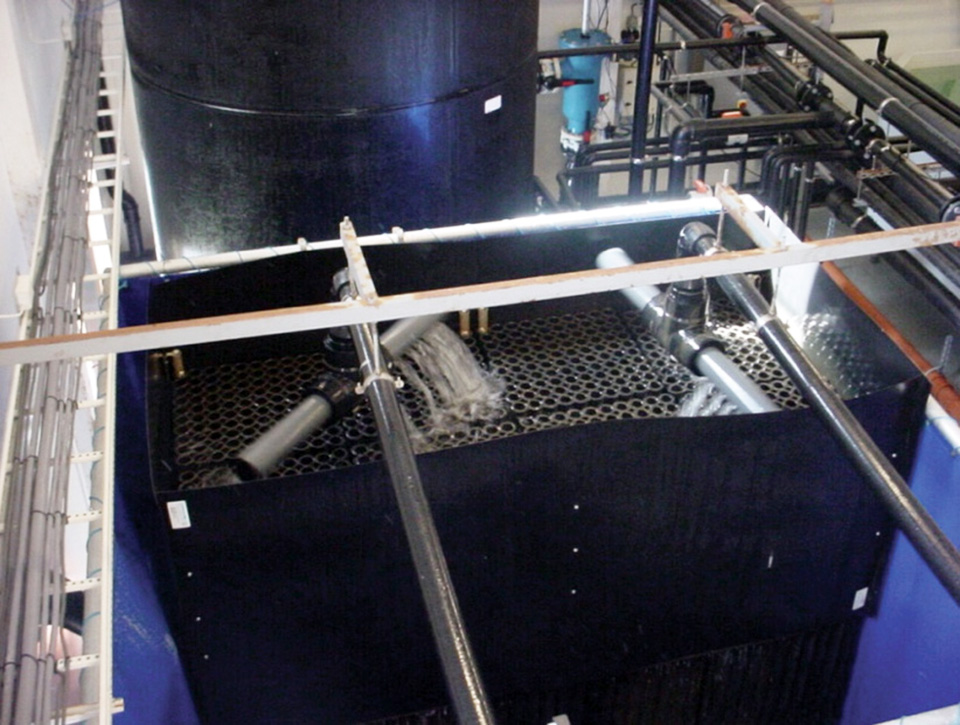

A review of unit processes in RAS systems

Since un-ionized ammonia-nitrogen and nitrite-nitrogen are toxic to most finfish, controlling their concentrations in culture tanks is a primary objective in the design of recirculating aquaculture systems.

Health & Welfare

Ammonia addition enhances microbial flocs in nursery phase for Pacific white shrimp

In a study, “pre-fertilization” in the nursery phase of a biofloc system for shrimp was tested. The objective was to accelerate the biofloc formation to minimize ammonia concentrations, avoiding high peaks during culture.

Responsibility

Ammonia nitrogen dynamics in aquaculture

The major sources of ammonia in aquaculture ponds are fertilizers and feeds, and problems with high ammonia are most common in feed-based aquaculture.