Fish farming at the highest level of productivity

In Germany, a country known for its traditional pond culture of carp and trout, closed recirculation systems are receiving increasing attention by commercial fish farmers. Heightened environmental awareness, decreasing wild catches, stricter regulations, low prices for carp and trout, and the shortage of high quality freshwater resources are stimulating an active search for profitable alternative fish farming technologies.

Fish production in recirculation systems represents aquaculture at its highest productivity level. Production water in these closed systems is mechanically and biologically filtered, heated, degassed, re-oxygenated and pumped back into the fish tanks. Production takes place independent of the outside environment (weather, industrial pollution, etc.) and under totally controlled production conditions. Because water requirements are minimal, recirculation units can be located nearly anywhere.

Development of recirculation systems in Germany

In Germany, the idea of recirculation systems was already established in the early 1970s. Intensive fish farming using filtration technology for water recycling had been developed from domestic wastewater treatment technologies. In East Germany (former GDR) in particular, efficient reuse of fish production water played an important role and received much professional acceptance. However, several problems including technological shortcomings, diseases, marketing and management problems prevented the economic success of recirculating fish culture systems during the industry’s first 20 years. Today, several farms operate profitably with an annual production of >50 tons per farm.

Species for commercial recirculation systems

Fish produced in closed systems are either high value species (more than 5 Euro per kilogram) like eel, sturgeon, flatfish, and others) or species with particular characteristics for intensive culture like rapid growth rates under high stocking densities, such as African catfish (Clarias garipinus or Heterobranchus sp.). The latter is adapted to very high densities of up to 250 kilograms per cubic meter. In Germany, most of the recirculation units are stocked with eel and European catfish (Silurus glanis).

A few operations grow African catfish, sturgeon, turbot and tilapia (Oreochromis niloticus). Although the world production of tilapia has increased drastically, according to the FEAP (Federation of European Aquaculture Producers), European farmers produced only approximately 300 tons in 1998. That means that – unlike in the U.S. and other countries – no tilapia boom has occurred in Europe.

New and promising for recirculating culture are the “seawater newcomers” like halibut, turbot and cod. Looking at other E.U. countries, the smolt production in the U.K. and Scandinavia has to be noted. The growth rate of smolts in recirculation systems is higher and meets the market demand of smolts >60 grams, to 70 grams. The Netherlands are setting the trend regarding African catfish and eel production, whereas eastern Europe represents successful production of sturgeon and European catfish.

Other applications for recirculation systems

Besides the commercial production of fish in recirculated units, recirculation research facilities also have great importance. Especially designed modular units are used for toxicological studies, environmental tests, husbandry or molecular genetic trials. The main objective for these closed recirculation units is to achieve totally controlled environmental conditions, without water quality changes, even with fluctuating stocking densities.

Fish families can be tested in parallel for selection programs (pedigree family selection, etc.) without marking the fingerlings within one group. Individual classification of small fish is one of the main problems of fishery research. The comparison can be carried out under standardized environmental conditions, which drastically reduces any potential environmental effect on test results. These closed recirculation, research facilities are designed in modules, are simple to setup and operate, and have low maintenance requirements.

Schmidt-Puckhaber, Data from a modern recirculation system for eel production, Table 1

| Parameter | Value |

|---|

Parameter | Value |

|---|---|

| Stocking density (ongrowing area) | 80 - 125 kg/m3 |

| Stocking density (fingerling area) | 60 - 100 kg/m3 |

| Production area | 4 m2/t annual production |

| Water treatment area | 1.25 m2/t annual production |

| Total energy requirements | 0.4 kW/t annual production |

| Heating energy requirements | 0.15 kW/t annual production |

| Oxygen requirements | 0.85 t O2 /t annual production |

| Freshwater requirements | 0.3 m3/d x t annual production |

| Feed requirements | 1.3-1,4 kg/kg fish |

| Productivity of Labor | > 60 t/person |

Latest developments in recirculation management

Recent developments in management practices for recirculating fish farming systems include:

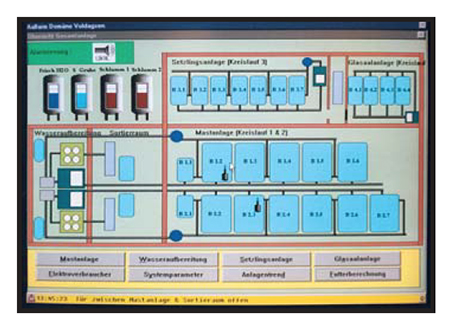

- Automated and direct measurement of all relevant water quality parameters (oxygen, temperature, pH and others), and inputs (heating energy, electrical energy, oxygen consumption and food supply). All parameters can reviewed on a computer screen, and trends can be compared over any period of time. This precise evaluation of important economic parameters supports profitable production by reducing variable costs and maximizing utilization of input factors.

- Minimized technical risk due to double (redundant) and independent monitoring, e.g. using two probes in each tank, oxydator control via oxygen content and gas pressure, pump sumps are controlled by level and pressure control, etc. All electrical components are monitored using PTA resistors.

- Production control via modem. Authorized personnel can view the status of the plant on-line, and control the production processes from a remote PC. Fish farm suppliers can also follow the production processes and respond as needed.

Conclusion

Several recirculation fish farms currently operate profitably in Germany, with annual productions of >50 tons per farm. Most of these farms produce eel and European catfish. However, compared to conventional pond and cage farming, fish production from recirculation systems is still low. Considering the many positive aspects of recirculation systems, we believe that intensive fish culture in recirculation systems will have widespread use in the near future.

(Editor’s Note: This article was originally published in the June 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Birgit Schmidt-Puckhaber, Ph.D.

Fischtechnik Germany

Fischtechnik Fredelsloh GmbH

37186 Moringen

www.fishlink.com/fischtechnik

Tagged With

Related Posts

Innovation & Investment

Aquaculture Exchange: Carsten Krome, Alimentos Ventures

A business accelerator helps small businesses grow and ready themselves to capitalize on institutional investment opportunities. Sounds exactly what the aquaculture industry needs. Carsten Krome tells the Advocate about the various business models his new firm is investigating.

Health & Welfare

Eel production in Europe

After rapid expansion of glass eel culture in the mid-1990s was followed by overproduction, pricing problems, glass eel shortages and NGO pressures, European Union countries adopted national management plans for the eels. Importation of consumption eels was stopped, and exportation was phased out.

Aquafeeds

Microalgae provide food, feed, fuel

About 30 percent of global microalgae production goes to animal feeds, with large applications in aquaculture, particularly for larval stages.

Intelligence

Spotted wolffish culture

Spotted wolffish exhibit attractive culture characteristics, including high value, high growth rates at high stocking densities, excellent fillet yield, nonaggressive behavior and few disease problems.