Minnesota company offers automated continuous monitoring system for aquaculture pathogens

Nucleic Sensing Systems, or NS2, says it can help aquaculture producers by looking at microscopic water droplets for signs of diseases and pathogens. The company’s “Tracker” product can do so in the field in an automated way, without requiring any personnel on-site. As a result of what this capability could mean for fish farming, Nucleic Sensing Systems is a finalist for the Global Seafood Alliance’s 2021 Global Aquaculture Innovation Award.

Tracker is a field-deployable, continuous-flow nucleic acid detection tool. It can monitor for and alert to the presence of bacteria, viruses, invasive species, mites, harmful algal blooms, or any other living organism of interest to an aquaculture manager, according to CEO Edgar Rudberg. “It is essentially a biological smoke alarm,” he said.

(Editor’s note: Nucleic Sensing Systems and the two other Global Aquaculture Innovation Award finalists will present at the final virtual GOAL session in mid-November. Look for Advocate profiles on the other two finalists in the next two weeks.)

Armed with this information, managers can begin mitigation measures and then see how the situation changes, maximizing productivity.

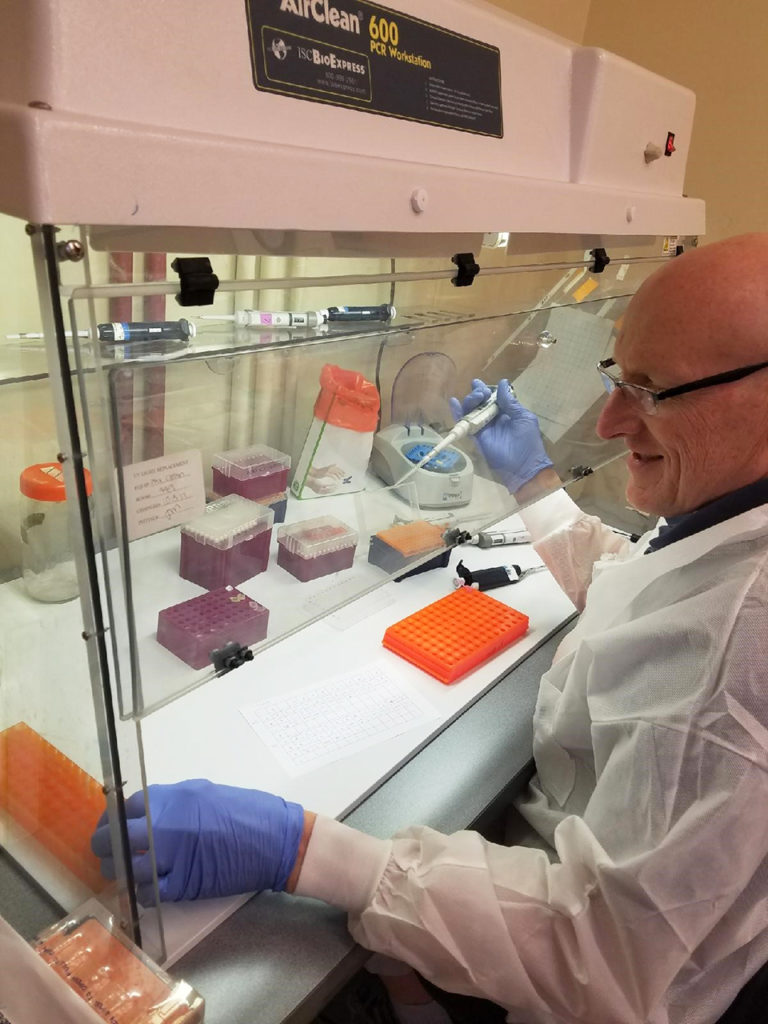

The basic technology concept came from work done in part by Cody Youngbull, who was investigating aquatic digital droplet PCR at the University of Montana and is now an advisor to NS2. Polymerase chain reaction (PCR) uses biochemicals to make many copies of small sections of DNA, with an extension of the technique making it possible to do the same amplification for RNA. PCR technology identifies diseases in people, such as the nasal swab tests done to detect COVID-19.

In NS2’s Tracker, the process begins with the machine taking in a water sample and then splitting it into 5-microliter (less than 0.0002 ounces) droplets. The RNA or DNA inside these microdroplets then undergoes the PCR process, with only those segments that match a specific sequence amplified and tagged with a fluorescent dye. Because thousands to millions of copies are made, only a very small amount of a particular nucleic acid sequence need be present in a microdroplet.

“We can detect as little as one DNA or RNA strand,” Rudberg stated.

The total time from a sample going into the machine and an answer coming out is less than an hour, he added. In contrast, the standard approach requires drawing a water sample, taking it to a lab, and then running an analysis, a process that can take days. It also can involve many manual steps.

Any monitoring system has to deal with false negatives, times when the device mistakenly says there is no problem, and false positives, instances when the machine erroneously says there is a problem. Tracker minimizes both types of false readings through a variety of methods, according to Rudberg.

First, the system uses only known and scientifically vetted PCR biochemicals. This approach ensures that Tracker detects what is of interest, Rudberg said.

The system has four different banks, each of which can have its own set of biochemicals. So, it can monitor for different biological problems, such as two distinct diseases and mites, at the same time, while also running a control to further enhance accuracy.

Innovation Award 2020 finalist: Simao Zacarias’ shrimp eyestalk ablation research

A secondary protection against false alarms is the splitting up of the sample into microdroplets and continuous monitoring, which means intake and processing of a new sample can happen every few minutes. Many tests, therefore, can be run in a short time, reducing the impact of a mistake in any single measurement.

“The more samples you get, the less likely you’re going to have an error because it becomes a statistical wash,” Rudberg pointed out.

The system is rugged, stores months of biochemical consumables, and requires so little power that it can run on solar cells, according to NS2 documents. Tracker weighs about 30 pounds and is about the size of carry-on luggage, Rudberg said.

Results are available through a cloud-based graphical user interface. With this capability, aquaculture producers could keep an eye on different production sites at once.

Tracker has had field deployments in federal hatcheries and NS2 has already sold units to the U.S. government. Field tests are now underway at private hatcheries. The product is in a beta stage right now, with Rudberg predicting a fully commercialized product will be ready for purchase by the end of 2022. The projected price is about $75,000, with ongoing service fees because of the cloud connection.

There could be other uses of the technology. Possibilities include agriculture and wastewater treatment applications.

But the first target is aquaculture. Being a finalist for an Innovation Award is a welcome recognition of the potential for the technology, Rudberg noted.

“We just feel so honored to have been included in this,” he said. “We’re obviously very passionate about the work that we’re doing. It’s just so exciting to have others feel the same way.”

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Hank Hogan

Hank Hogan is a freelance writer based in Reno, Nevada, who covers science and technology. His work has appeared in publications ranging from Boy’s Life to New Scientist.

Tagged With

Related Posts

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.

Health & Welfare

AHPND is a chronic disease in Pacific white shrimp from Latin America

There is a new phase of infection for Acute Hepatopancreatic Necrosis Disease on Latin American shrimp farms, a contrast to observations in Southeast Asia.

Innovation & Investment

Global Aquaculture Innovation Award 2019 finalist: Ace Aquatec

Global Aquaculture Innovation Award finalist Ace Aquatec’s Humane Stunner Universal easily renders fish unconscious for a more humane slaughter process.

Innovation & Investment

High-density shrimp producer wins innovation award

Camanor Produtos Marinhos Ltda. operates a land-based, multi-species concept for sustainable shrimp production called AquaScience. The Global Aquaculture Alliance has named Camanor the winner of its annual Aquaculture Innovation and Leadership award. Director Werner Jost discusses the process.