Domestication has been expensive and time-consuming

The Atlantic halibut (Hippoglossus hippoglossus) is a large deep-water flatfish that can grow up to 200 kg in the wild. It is usually found around Iceland, Greenland, northern Norway and eastern Canada.

In the last few decades, the annual wild catches of Atlantic halibut have decreased from 7,000 to 3,000 metric tons (MT). Today, however, farmed Atlantic halibut offer a year-round protein source of high quality for national and international markets.

Juvenile production

Atlantic halibut go through metamorphosis at lengths of 30 to 40 mm and switch from a pelagic to benthic life stage. The most critical period during aquaculture production is before the fry reach 5 grams. High mortality during the fry phase and difficulties with first feeding, which requires live food, continue to be the greatest bottlenecks in halibut farming. Major prerequisites for good survival are stable and high water quality, proper management and feeding, stable temperature, and good hygiene.

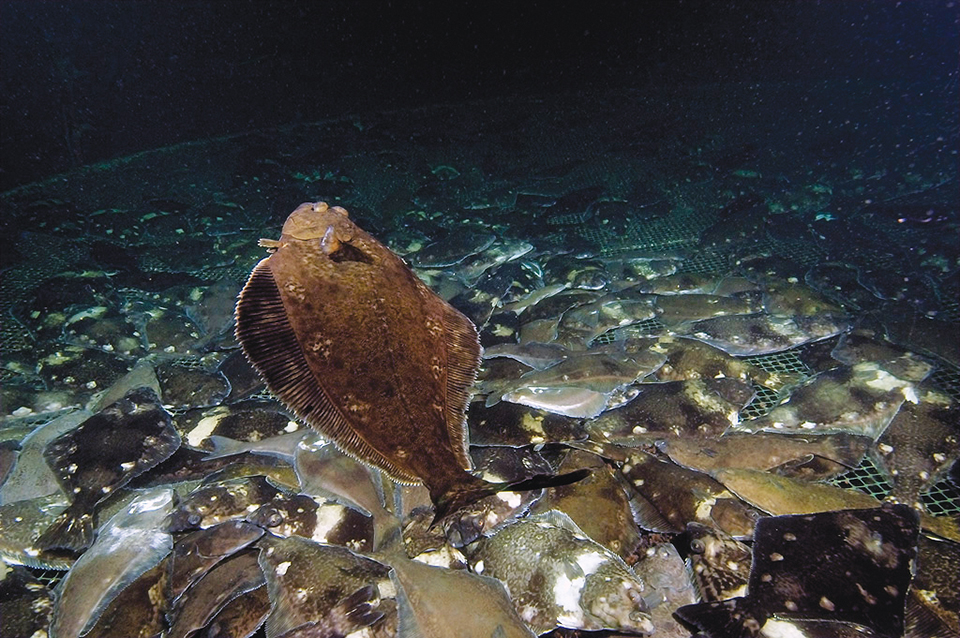

In early stages, juvenile halibut show a positive growth response with the use of artificial light that is independent of water temperature. Growth rates usually increase with increasing photoperiod and are highest when light is provided 24 hours per day. Although optimum temperatures vary with fish size, the range lies 12 to 15 degrees-C for fish of 5 to 70 grams. During the fry and juvenile stages, halibut seems to be social toward siblings and may form two or three layers in production tanks.

Grow-out

Halibut grow-out takes place in land-based tanks and/or sea cages. The halibut juveniles are stocked for ongrowing at 50 to 500 grams. Farmers aim to grow the fish to 5 kg within 30 months. However, growth data from farms shows that halibut typically reach 3 kg after 36 months.

Maturation usually occurs in 2- to 3-year-old halibut under 2 kg. Only a problem for males, early maturation leads solely to stagnation in growth, not poorer quality or higher mortality.

Halibut can be grown at densities equivalent to 100 to 200 percent of the available surface area. This means that 2-kg halibut can be farmed at 25-50 kilograms per square meter, and 10-kg halibut can be farmed at 50 to 100 kilograms per square meter.

Production, pricing

Global aquaculture production of Atlantic halibut in 2004 was 850,000 juveniles, with Norway producing 350,000 juveniles from 10 hatcheries. The remaining animals were produced in Iceland. Global harvested production has increased substantially (Table 1), with Norway and Iceland the pioneering countries. According to the Norwegian Export Council, the volume of halibut produced in 2005 was close to 1,000 MT.

Drengstig, Global production of farmed halibut, Table 1

| Year | Slaughtered Volume (mt) |

|---|

Year | Slaughtered Volume (mt) |

|---|---|

| 2004 | 634 |

| 2003 | 425 |

| 2002 | 420 |

| 2001 | 376 |

| 2000 | 549 |

| 1999 | 451 |

| 1998 | 290 |

| 1997 | 113 |

Norwegian exports have steadily increased since 2002, when the total export of halibut was approximately 400 MT. In 2005, Norway exported 549 MT of halibut with a value of 37.3 million Norway kroners (NOK) or U.S. $5.6 million – an increase of 30 percent from 2004. The average price decreased from 71.00 NOK (U.S. $10.72) kilograms per in 2002 to 67.90 NOK (U.S. $10.26) kilograms per in 2005, and few farmers made any profit.

Halibut production in Norway takes place at three rather large farms and several smaller facilities. Thus, the Norwegian production rate is rather easy to estimate and forecast. For example, Inge Midtbø, manager of Nordic Seafarm, which harvests 250 to 300 MT per year, expects an increased production this year of about 20 percent. His farm gets 75 NOK (U.S. $11.33) kilograms per for gutted halibut and is experiencing increased market demand.

R & D needs

The domestication of Atlantic halibut has been an expensive and time-consuming process for the Norwegian aquaculture industry. Despite a major effort to industrialize halibut farming from the initial work in Norway in 1983, halibut farmers still struggle to make ends meet.

Although the challenges of diseases seem to be under control, a stable production of viable juveniles with the correct shape, pigmentation, and morphology is the main issue for the future. In the grow-out phase, the industry has limited knowledge of fish health concerns, water quality, nutritional needs, and problems with early maturation in males.

Despite such problems, significant advances have improved production and made it more predictable in recent years. Important improvements included the development by feed companies of special diets to replace live artemia, which can be difficult to manage and represent a critical risk point for introducing pathogen bacteria.

The use of deeper tanks and sea water sterilization with ultraviolet light or ozone have significantly increased the survival of juveniles. Promising results at Scottish hatcheries came from adding brine to increase salinity to 35 ppt in juvenile tanks to reproduce the natural conditions found at the 600-meter depths halibut naturally inhabit.

Current research on farming Atlantic halibut is focused on feed quality and its effects on weaning, metamorphosis, growth, and feed utilization. For example, the fatty acid composition of halibut diets seems to relate to abnormal development in halibut larvae. Another recently reported topic is how changes in photoperiod influence metamorphosis.

Further, the industry needs to guarantee product quality according to increasing consumer standards and demands. Thus, several companies now provide software tools for traceability and production planning of the entire Atlantic halibut aquaculture value chain.

(Editor’s Note: This article was originally published in the April/May 2006 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Asbjørn Drengstig, M.S.

Hobas Water Engineering Ltd.

Kjelsbergtunet 29, 4050 Sola, Norway -

Dr. Asbjørn Bergheim

IRIS-Akvamiljø

Stavanger, Norway

Tagged With

Related Posts

Health & Welfare

Integrated larval-nursery system for California halibut

Hubbs-SeaWorld Research Institute developed an integrated larval-nursery recirculating aquaculture system for California halibut utilizing shallow raceways for juvenile culture.

Innovation & Investment

Norway showcases halibut farm as sustainability star

Recognizing its potential as a sustainable fish producer, Norway highlights land-based halibut farmer Sogn Aqua in the debute of The Explorer digital showroom. The Advocate recently paid a visit to the farm in Ortnevik.

Health & Welfare

Advances in fish hatchery management

Advances in fish hatchery management – particularly in the areas of brood management and induced spawning – have helped establish aquaculture for multiple species.

Intelligence

Farmed white halibut

Farmed white halibut initially undergo an 18-month hatchery and nursery stage in land-based tanks. The fish have gained status as a high-quality seafood delicacy.