Support more efficient aquaculture production by promoting health and growth through value-added, novel ingredients

Marine shrimp aquaculture has developed tremendously over the past four decades. Farm production of various species currently contributes more than 50 percent of global demand for shrimp (almost 4.5 million metric tons according to the latest GOAL data by Anderson, et al.).

However, the industry continues to be significantly affected by a number of major diseases, and uncertain and shifting global prices are negatively impacting many producers. Thus, the development and expansion of markets and increasingly efficient production are important goals for the entire industry that can be achieved through innovation, with particular regard to feeds.

Production inefficiencies impact many animal producing industries. Shrimp farmers inevitably encounter major diseases and some struggle to provide better health management. Furthermore, reduced growth rates limit their potential and the use of antibiotics can foster marketplace resistance. Faster growth, enhanced survival rates and improved organoleptic product characteristics are key goals for all animal production industries, including aquaculture.

Impact of diseases

Shrimp is one of the most valuable aquacultured species in the world. However, global farmed shrimp production has been negatively impacted by several major viral, bacterial and parasitic diseases since its beginning several decades ago, and more seriously in the last two decades. Foremost among these major diseases are those of a viral origin, including the Infectious Hypodermal and Hematopoietic Necrosis Virus (IHHNV), Yellowhead Virus Disease (YHD), Taura Syndrome Virus (TSV), White Spot Syndrome Virus (WSSV) and the Infectious Myonecrosis Virus (IMNV). Some of the above have been affecting the industry since the early 1980s and have caused billions of dollars in losses in shrimp farming areas in Asia and the Americas.

More recent diseases include Acute Hepatopancreatic Necrosis Disease (AHPND) or Early Mortality Syndrome (EMS), which is caused by a bacterium (Vibrio parahaemolyticus) that causes hepatopancreas dysfunction and secondary Vibrio infections. Another recent disease is hepatopancreatic microsporidiosis, also called Enterocytozoon hepatopenaei (EHP), caused by a tiny microsporidian parasite that affects shrimp by disrupting their digestive systems. EHP has affected shrimp production and caused widespread problems throughout the main shrimp producers in Asia and has also been reported in the Americas. And there are also several newer, lesser known diseases like White Feces Syndrome, and the newly discovered iridescent virus that causes severe disease and high mortality in farmed Pacific white shrimp in China, named as Shrimp Hemocyte Iridescent Virus (SHIV) and various others emerging diseases of importance.

These diseases have caused significant economic losses to the industry, amounting to at least $45 billion globally in the past decade, according to Dr. Andy Shinn, director of Fish Vet Group Asia. WSSV alone has caused accumulated losses of around $15 billion, and Dr. Shinn has also estimated that AHPND causes value-added losses of around $1.7 to $2 billion annually.

Diseases also have a significant negative effect on investors, as the history of the industry is one of periodic, major disease outbreaks and continuous health management issues that upset markets and supply chains.At the recent GOAL 2018 meeting in Ecuador, “diseases” was once again identified by survey respondents from Asia as the top challenge faced by the industry. Many investors see much potential in shrimp farming and consider it a very good opportunity but they are also concerned with managing these risks.

Health-promoting functional ingredients emerge

There are many functional ingredients or additives that promote the growth, development and health of farmed shrimp. Some ingredients or additives can improve immune response and other physiological responses and needs like reproduction, while others support the animals’ responsesagainst oxidative stress, susceptibility to some disease and environmental stressors like water quality, temperature, fluctuations of oxygen and salinity. Some additives aid the function of the gastrointestinal tract function, including rapid repair of the gut, and improved flora. Several functional ingredients are currently used in the manufacture of commercial shrimp feeds, including phytogenic substances, immune-stimulants, enzymes, mycotoxin binders, organic acids, probiotics/prebiotics, nucleotides and others.

For example, nucleotides play an important role in animal growth during the early stages because of fast growth and cellular replication; in enhancing disease resistance and tolerance to stress; in supporting and promoting innate and adaptive immunity; in the biosynthesis of non-essential amino acids.

Dietary nucleotides promote shrimp growth and performance, and the effects of such feeding of young shrimp is reflected in improved specific growth rates and weight gains to harvest sizes. Improved feed conversion rates and more efficient utilization of lipids and proteins has also been reported. Dietary nucleotides also improves the efficiency of digestion and nutrient absorption, and reproductive performance including egg diameter, absolute fecundity and latency period.

As fishmeal inclusion levels continue to be reduced, driven by economics and sustainability pressures, supplementation with novel functional ingredients will likely have a growing importance for optimal performance of several key production parameters in farmed shrimp production.

Menon Renewable Products, Inc., is engaged in the development and production of sustainable, high-quality, protein and nutrient-rich animal feed products. Our product line, known as MrFeed® (named for Menon Renewable Feed), provides a renewable alternative to non-sustainable feed ingredients currently in the market, such as fishmeal and others.

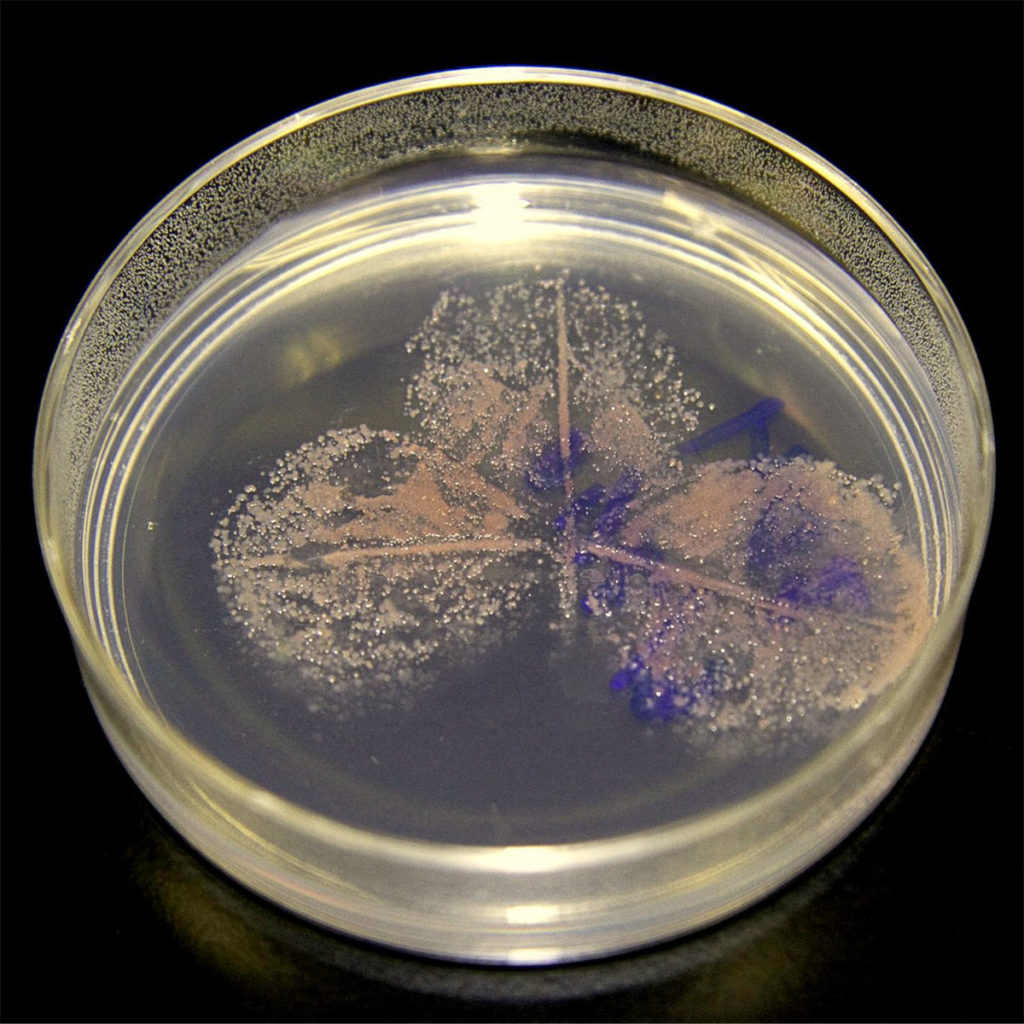

Our proprietary technology, a biomass conversion process called CelTherm®, converts organic feedstocks into high-value animal feed products so that we can produce high-performance feeds at a competitive cost. Ours is a complete bioconversion process in which organic material from plant-based crops is hydrolyzed into cellulosic sugars and fermented, thus oligomerizing molecules to create custom-tailored formulations for feed applications. The process generates proteins, nucleotides and peptides that are effective for boosting the overall health and immunity of animals.

After several years of research, testing and continued product and process development, we started commercial production of our products under the brand MrFeed® for use in aquaculture, poultry and livestock. We have commercial production facilities in India, the United States and Canada, strategic partners in 12 countries around the world, and can produce custom tailored ingredients to suit several aquacultured species.

For the last three yearswe have conducted – and continue to do so – extensive testing of our products in several Asian and Latin American countries and under commercial production conditions with the support of many shrimp farmers.

I recently had the opportunity to present our company and products at the recent F3 Challenge in San Francisco, Calif., USA. Results of our tests with our shrimp ingredients incorporated into commercial feeds at several commercial shrimp farms in India, Vietnam, Indonesia, Malaysia, Mexico, Honduras and Panama demonstrated significant improvement in shrimp growth, survival and feed conversion rates, even in the presence of major diseases like WSSV and White Feces Syndrome.

Our shrimp trials continue as we expand our commercial presence in major shrimp farming areas, and we are also involved in and expanding our research efforts to other commercially-important species like salmon and trout, tilapia, pangasius, pompano, yellowtail, barramundi and others to responsibly support the improvement of key production parameters, and industry sustainability and profitability.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Suresh M. Menon, Ph.D.

President

Menon Renewable Products, Inc.

500 La Terraza Blvd.

Escondido, CA 92025 USA

Tagged With

Related Posts

Aquafeeds

Single-cell protein aquafeed ingredient first to gain GRAS designation

Massachusetts-based biotechnology firm KnipBio is the first single-cell protein manufacturer serving the aquafeed industry to earn Generally Regarded as Safe designation from the U.S. Food and Drug Administration.

Aquafeeds

Aquafeed moonshots at the F3 ‘talent show’

At the F3 (fish-free feed) Companies Got Talent event in Burlingame, Calif., last week, alternative (non-marine) aquafeed ingredient companies spoke of decoupling aquaculture from fishmeal and fish oil in their quest for greater sustainability.

Aquafeeds

Is TerraVia Silicon Valley’s answer to sustainable seafood?

Like so many innovative solutions achieved in digital technology, a potential fix to aquaculture’s existential issue – the sustainability of feeds – was born in Silicon Valley. In a garage, no less.

Aquafeeds

A new nutrient for aquaculture, from microbes that consume carbon waste

Biotechnology firm NovoNutrients aims to produce a line of nutraceutical aquafeed additives as well as a bulk feed ingredient that can supplement fishmeal. Its process includes feeding carbon dioxide from industrial gas to a “microbial consortium” starring hydrogen-oxidizing bacteria.