Innovative technology to provide low-cost, highly sustainable option to help address global nutrient shortcomings

More than two billion people worldwide are micronutrient deficient, as estimated by the World Health Organization (WHO). Vitamin A and D deficiencies are of particular concern, with 33 percent of children and one in six pregnant women lacking sufficient vitamin, and regional deficiencies can be especially pronounced. For example, in Ghana more than 76 percent of children are vitamin A deficient, causing widespread mortality and blindness, while in India 85 percent of citizens are vitamin D deficient, causing cardiovascular diseases, osteoporosis and rickets. Even in the United States, more than 40 percent of the population is vitamin D deficient.

Bivalve shellfish – such as clams, oysters, mussels and scallops – are a highly attractive yet underutilized food source with the capacity to provide the global population with key nutrients. Bivalves have a higher protein content than beef, are a rich source of omega-3 fatty acids, have some of the highest levels of key minerals of all animal foods, and are very sustainable to farm. There is great potential to sustainably expand bivalve aquaculture worldwide, with more than 1,500,000 square kilometers available for sustainable low-cost industry development. However, although bivalves are nutrient-rich, the level of nutrients they deliver naturally is unlikely to solve global nutrient deficiencies, but innovations in bivalve production can change this.

The “depuration” stage of bivalve production, during which bivalves are held in cleansing tanks for 48 hours after harvest, represents a unique opportunity for integrating nutrients into the bivalve gut and surrounding tissue. As humans consume the entire organism including the gut when they eat a bivalve, these nutrients will be available to humans. Micronutrient fortification during the depuration stage could allow the levels of a specific nutrient such as vitamin A or D to be increased in the food supply to meet specific regional needs. As bivalves also tend to be consumed locally, this would be a highly efficient and targeted method to tackle nutrient deficiencies. There is however a need for a method to deliver micronutrients to bivalves during depuration.

Novel microencapsulated feeds can provide a delivery vehicle for micronutrients to bivalves; the microcapsules are digestible by bivalves and can improve bivalve growth and sexual maturation. Mass production is simple and cost-effective, and properly sealed, the dry microcapsules have shelf lives in excess of one year. Capsules are designed to maximize feeding efficiency and minimize nutrient leaching to water, and the specific nutritional content of the microcapsules can easily be tailored. For depuration, this makes it possible to create microcapsules containing only the micronutrients required by the human population for fortification, without any other food, minimizing the overall quantity of microcapsules required.

This article – adapted and summarized from the original publication (Willer, D.F. and D.C. Aldridge. 2020. Vitamin Bullets. Microencapsulated Feeds to Fortify Shellfish and Tackle Human Nutrient Deficiencies. Front. Nutr., 20 July 2020) – reports on a study to formulate and characterize a new form of micronutrient microcapsules, find out whether bivalves would consume them, and whether this would lead to elevated micronutrient levels in bivalve tissue.

Study setup

We carried out our bivalve nutritional fortification experiments at the University of Cambridge (UK) under conditions to simulate commercial depuration protocols. Experiments were carried out in a controlled temperature room held at 15 degrees-C, in constantly aerated tanks each containing 1 liter of artificial seawater at salinity 30 ppt. Each tank contained one adult Pacific giant oyster (Crassostrea gigas) received directly from commercial depuration tanks at Colchester Oyster Fishery (UK).

Each oyster was fed a 50:50 blend of both vitamin A and D microcapsules at doses and timeframes feasible during the 48-hour depuration period. There were 105 individual tanks, allowing for five biological replicate oysters to be fed microcapsules at doses of 3, 6 and 9 percent dry weight (DW) feed per DW oyster over 2, 4, 8, 16 and 32 hours, alongside 0 and 32-hour controls at doses of 0 percent. Feed concentrations refer to the initial quantity of feed given at time = 0; no feed was added to the tanks during the remainder of the course of the experiments. At the end of each timeframe, each oyster was immediately removed from its tank. Oysters were then shucked and any water inside the shells was drained off. The entire soft tissue of each oyster was then removed and frozen for analysis.

For detailed information on the experimental design; microcapsule manufacture and characterization; oyster nutritional fortification; and vitamins A and D analyses, refer to the original publication.

Results and discussion

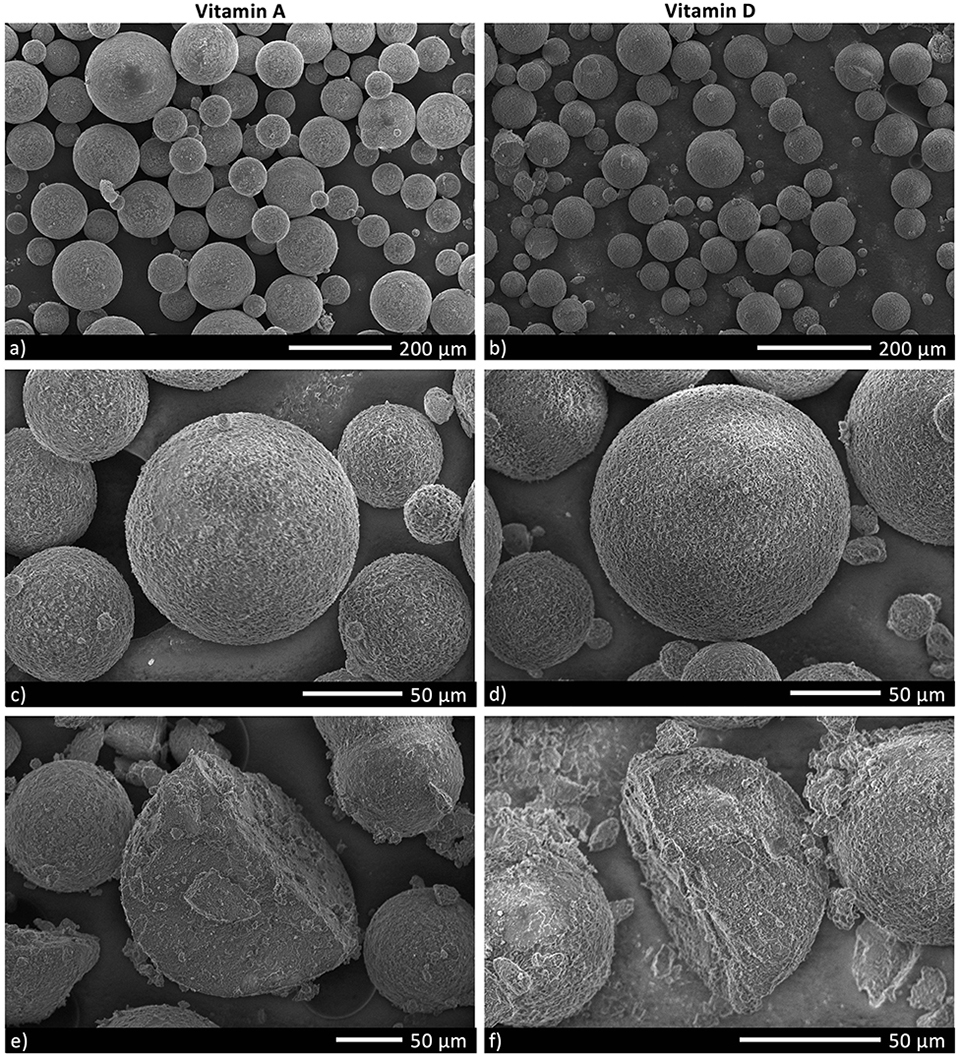

We developed microcapsules with appropriate properties to achieve efficient capture and digestion by filter-feeding bivalves. The consistent spherical morphology and size range of 50 to 200 μm, were of a shape and size that C. gigas could harvest from the water. For both vitamin A and D microcapsules, particles at the peaks around 0.5 and 10 μm likely represent ingredient fragments which can be seen on close inspection of the SEM images (Fig. 1). The scarcity of these fragments confirms high purity in the microcapsule samples. The roughened surface structure of the microcapsules will likely have improved their palatability to bivalves and the lack of air pockets helped ensure neutral buoyancy so that the particles remained at the appropriate position in the water column for filter feeders to access. These physical properties made the microcapsules an ideal delivery vehicle for the micronutrients in our study and the key component for us to be able to nutritionally fortify bivalves.

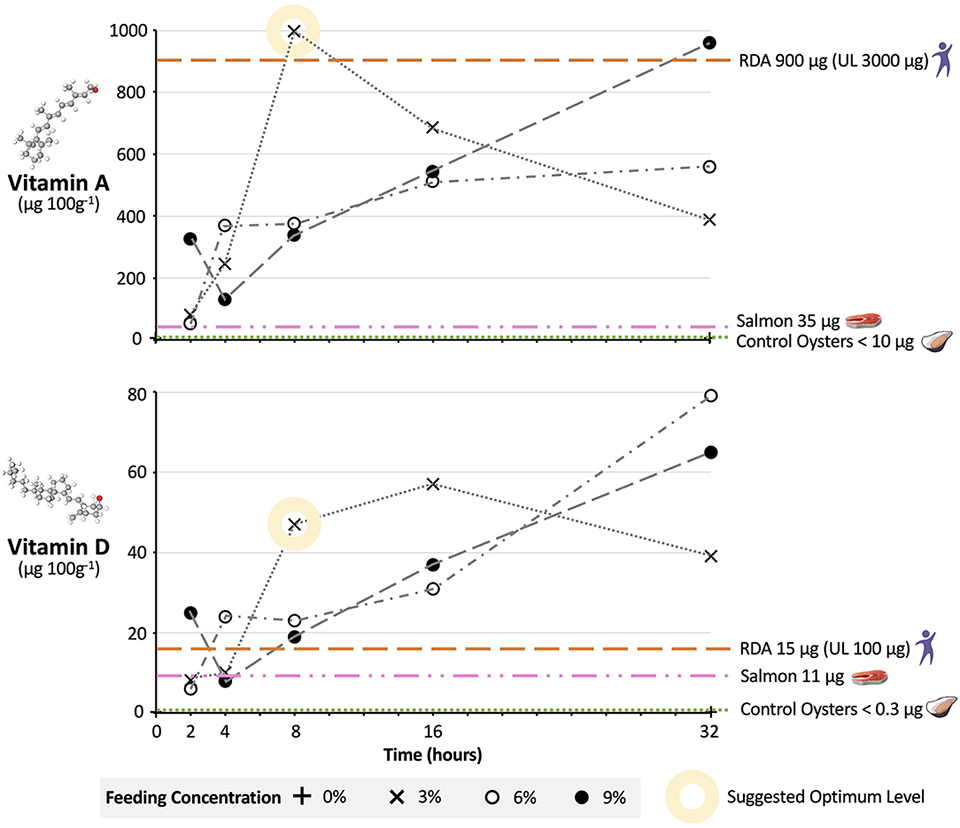

Feeding micronutrient microcapsules under depuration conditions led to successful fortification of bivalves, and we suggest that for vitamins A and D an optimum dose regarding feed concentration and timeframe might be 3 percent for 8 hours. After an 8-hour timeframe, vitamin A and D levels in oysters were higher on the 3 percent feed than on the 6 or 9 percent feed. This relationship is less surprising than first appears; when bivalves are exposed to too much food, they will reduce their feeding rate to avoid overloading the filtering system on their gill stacks. The only other feed concentrations and timeframe that resulted in comparable vitamin levels to 3 percent at 8 hours were 6 and 9 percent at 32 hours.

However, feeding at this higher dosage would not be optimal, representing a wasteful and excessive use of feed resources to achieve a very marginal further increase in oyster vitamin levels. This is demonstrated by the lower yields of the 6 and 9 percent treatment at 32 hours relative to the yield of the 3 percent treatment at 8 hours. We note that the drop-off in micronutrient levels after 32 hours for the 3 percent feed is likely occurring as by this point the oysters have depleted the microcapsules in the tank and are digesting and excreting the excess vitamin A and D they do not need. Therefore, we suggest that if an 8-hour fortification period is used, it should be done at the later stages of depuration to reduce the risk of bivalves excreting nutrients in feces. Optimizing concentration and timeframe are clearly important in ensuring efficient use of resources.

Oysters fortified with vitamins A and D at 3 percent for 8 hours also performed well regarding nutritional value when compared to other foods and the RDAs, providing further support to our suggested optimum dose. In a small portion (100 grams, or three small or two large oysters) of oysters fortified at the 3 percent 8-hour dosage, vitamin A and D levels were 997 and 47 μg/100 grams, respectively. This exceeds the levels in natural oysters (<10 and <0.3 μg/100g). More importantly, it far exceeds the levels found in one of the best natural sources of vitamin A and D; salmon (37 and 11 μg/100g, Fig. 2).

In addition, a 100-gram serving of oysters fortified at 3 percent for 8 hours meets U.S. Department of Health RDAs for vitamin A and D without exceeding Upper Daily Limits (UL). Based upon predicted manufacturing, distribution, and implementation costs for the microcapsules, fortification would add just $0.0056 to the cost of a single oyster, which could readily be recuperated through a small additional increase (~0.9 percent) in oyster retail price. This offers strong hope for people in deficient populations: just two fortified oysters a day could provide them with all their vitamin A and D needs in a highly bioavailable form.

There are important steps that can be made by the research and industrial community to realize the potential of bivalves and microencapsulation innovations to help tackle micronutrient deficiencies worldwide. Researchers will need to carry out larger laboratory studies with a greater number of replicates to enable quantitative analysis of the individual variation in vitamin uptake by bivalves; such variation is often seen in the fortification of foods including eggs and meat via dietary intervention.

There is also a need to assess the bioaccumulation of microencapsulated vitamins specifically into bivalve storage tissues, the impact of high-level vitamin accumulation on bivalve physiology, and whether the presence of microcapsules in the bivalve gut promotes the micellarization [the formation of micelles, aggregates of surfactant molecules dispersed in a liquid, forming a colloidal suspension] and absorption of vitamins in the human gut. There is, thus, a need for proof-of-concept trials on humans. Future studies would need to feed fortified bivalves to human participants and assess the impact on physical health and blood markers, to establish the true bioavailability of the initially microencapsulated micronutrients to people.

At an international scale, there will be a requirement to tailor the selection of vitamins encapsulated and the microcapsule dosage given, in order to apply the technology to global regions with specific nutritional deficiencies or food consumption patterns. Despite the increased cost of fortified oysters relative to conventional oysters being small (0.9 percent), and the falling price of oysters with new breeding innovations and the use of fast-growing triploids, oysters remain one of the more expensive bivalves. Therefore, it will also be crucial to apply the technology to other bivalve species including mussel and clam species such as green mussels (Perna viridis) and Japanese carpet shells (Ruditapes phillippinarum) which are cheaper to farm in many developing regions. Completion of these steps will help enable the scale-up of micronutrient fortified microcapsules at the commercial level.

There are major economic, sustainability and health wins that can be made from integrating micronutrient-fortified bivalves into our global food system. The ability to use tiny doses of microcapsules to fortify a food organism at its final life stage has major cost advantages. It represents a cheaper option than attempting to fortify other terrestrial animals or fish, which need to be fed fortified feeds for a greater period of their lifespan. Bivalves are also the most sustainable animal food on the planet, with farming having important ecosystem benefits, so there are conservation gains that could be made from bivalve aquaculture expanding in place of other meat production. Most importantly, microencapsulated micronutrients combined with bivalve aquaculture can act as a next-level tool to target and tackle nutritional deficiencies worldwide. Just two fortified bivalves a day has the potential to contribute toward saving and improving the lives of more than 2 billion people worldwide.

Perspectives

Our study marks the first successful fortification of bivalves with micronutrients beneficial to human health, using a novel microencapsulated feed supplied at the depuration stage of production. The microcapsules were tailored for optimal size, shape, buoyancy and palatability to maximize uptake by bivalves. Pacific oysters were selected as a case species, due to their sustainable production and economic importance as the most widely cultivated bivalve globally. Our study found that oysters fed vitamin A or D microcapsules at a dose of 3 percent over 8 hours had increased vitamin content, to the extent that two such oysters would provide enough vitamin A and D to meet human dietary RDAs. Fortification at this level would be highly cost-effective and offset by a small (0.9 percent) increase in retail price.

Further research studies and industry trials are warranted to realize the potential benefits of fortified bivalves to the global food system. These would provide a greater understanding of the inter-individual variation in micronutrient accumulation by bivalves, the bioavailability of delivered nutrients to humans, and the optimum combination of bivalve species, encapsulated nutrients, and fortification dose to help tackle nutrient deficiencies in specific global regions. Taking these steps can provide stakeholders in aquaculture to make an invaluable contribution toward improving the quality and sustainability of our global food system.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

David F. Willer, Ph.D.

Corresponding author

Aquatic Ecology Group, Department of Zoology, University of Cambridge Conservation Research Institute, University of Cambridge, Cambridge, United Kingdom -

David C. Aldridge, Ph.D.

Aquatic Ecology Group, Department of Zoology, University of Cambridge Conservation Research Institute, University of Cambridge, Cambridge, United Kingdom

Tagged With

Related Posts

Aquafeeds

Microencapsulated, composite-wall diets compare well to commercial feeds for shrimp larvae

Diet microencapsulation using a biopolymer composite wall is a novel way to protect diet ingredients against deteriorative mechanisms such as oxidation and leaching.

Aquafeeds

Formulated diets: Replacement for live food in marine fish larvae

Creating formulated diets for fish larvae is difficult because estimating nutritional requirements cannot be done using traditional nutritional approaches.

Aquafeeds

Is a ‘baby food’ bottleneck looming for aquaculture?

Global aquaculture, particularly farmed shrimp, depends on artemia for hatchery feeds. Supplies meet current needs, but growth will require alternatives.

Aquafeeds

Development, testing of microencapsulated Schizochytrium feeds for bivalve broodstock

Comparing performance of O. edulis broodstock fed microencapsulated Schizochytrium feed and live algae diets shows potential for bivalve hatcheries.