Dietary inclusion significantly alters fatty acid composition of shrimp

Rapid growth of aquaculture worldwide has become increasingly dependent upon the use of external feed inputs, and in particular upon the use of compound aquafeeds. Pressures to reduce fishmeal consumption for sustainability and economic reasons require intensive research efforts to find candidates to replace fishmeal.

Formulating low-fishmeal shrimp feeds requires the use of combinations of several ingredients, since most feedstuffs have significant nutrient and functional limitations and cannot be used individually at high levels in the diets of farmed shrimp.

Poultry by-product meal

Poultry byproduct meal (PBM), an ingredient with protein and essential amino acid profiles more favorable than those of plant protein ingredients, can replace about two-thirds of the fishmeal in shrimp diets without negatively affecting performance. Why further increases in the inclusion of PBM affects performance is a key area of current research.

One of the plausible reasons is the high level of fat in PBM. Feed intake could be affected due to PBM’s excessive energy:protein ratio. Further, the fat has a high n-6:n-3 fatty acids ratio when compared to fishmeal, and consequent alteration of the fatty acids ratio in feed may have a detrimental effect on shrimp performance. On the other hand, the fat in PBM is also a source of valuable nutrients, particularly phospholipids and cholesterol, for shrimp.

To better understand the nutritive value of the fat in PBM, the authors quantified various components of the fat, defatted PBM using super-critical fluid extraction, designed experimental feeds with various combinations of regular and defatted PBM, and conducted shrimp-feeding trials.

Supercritical fluid extraction

Extraction with supercritical fluid (SCF) has been found selective in the separation of desired compounds without leaving toxic residues in extracts and without the risk of thermal degradation of the processed product. PBM was supplied to the extraction column, which was subsequently connected to the laboratory-scale extraction system. The system was flushed with the supercritical fluid to remove air, and the heating mantles were activated to bring the column to process temperature.

An initial starting pressure was selected based upon experience and biomass architecture information. SCF in gas form was passed through the vessel at the selected pressure and temperature conditions for a period of time. The high-pressure stream of gas plus extracted material was then passed through a pressure-reduction valve into a filter flask, where the extractables precipitated. The atmospheric gas exited the flask and flew through a meter for integration of total volume. After allowing a desired amount of gas to flow through the extraction vessel, the flask was removed.

The procedure was repeated to collect multiple extracts from the same initial charge until the extractable material was depleted. Finally, the residual defatted PBM remaining in the vessel was collected.

Fatty acid profile

Analyses of the full-fat PBM, defatted PBM and extracted fractions for proximate composition, fatty acids, phospholipids and cholesterol were conducted to understand the levels of the fat components in the experimental ingredients. The data confirmed that supercritical fluid extraction effectively extracted cholesterol and neutral lipids into the liquid portion, but retained most of the phospholipids in the meal portion.

The extraction efficiencies were estimated to be 9.0, 78.3 and 59.0 percent for phospholipids, cholesterol and total lipids, respectively. In addition, 12.5 percent of the lipids in PBM are composed of phospholipids. Among the phospholipids, phosphatidyl choline (40.8 percent) was the most dominant, followed by sphingomyelin (11.4 percent), lysophosphatidyl choline (8.8 percent), phosphatidyl ethanolamine (7.6 percent) and phosphatidyl inositol (6.9 percent). The cholesterol content of PBM was estimated at 0.21 percent (1.7 percent of the lipids). The fatty acid profile of PBM is shown in Table 1.

Nates, Fatty acid profile, Table 1

| Fatty Acid | Fatty Acids (%) |

|---|

Fatty Acid | Fatty Acids (%) |

|---|---|

| 16:0 (Palmitic) | 23.34 |

| 16:1n-7 (Palmitoleic) | 7.44 |

| 18:0 (Stearic) | 5.73 |

| 18:1n-9 (Oleic) | 40.97 |

| 18:2n-6 (Linoleic) | 19.31 |

| 18:3n-3 (Linolenic) | 0.95 |

Experimental diets

Four diets with 0, 12, 24 or 36 percent inclusion levels of defatted PBM replacing the full-fat PBM and a reference diet with fishmeal were designed. The diets were formulated to contain 42 percent crude protein and decreasing crude fat and digestible energy. Analysis of the diets is presented in Table 2.

Nates, Proximate analysis, Table 2

| Nutrient (% as fed) | Feed 1 | Feed 2 | Feed 3 | Feed 4 | Reference Feed |

|---|

Nutrient (% as fed) | Feed 1 | Feed 2 | Feed 3 | Feed 4 | Reference Feed |

|---|---|---|---|---|---|

| Moisture | 8.05 | 7.72 | 8.33 | 8.18 | 8.32 |

| Crude protein | 42.68 | 42.26 | 40.93 | 44.03 | 42.74 |

| Crude fat | 10.54 | 10.27 | 7.47 | 6.20 | 8.06 |

| Crude fiber | 0.87 | 1.01 | 0.96 | 1.03 | 0.84 |

| Ash | 8.18 | 8.48 | 8.20 | 8.59 | 7.76 |

The diets were fed to shrimp of 4.1 g average initial weight for seven weeks. The shrimp were stocked at 20/m2 in circular 1,800-L microcosm tanks that are part of the Shrimp Nutrition Research Center of the Department of Fisheries in Brunei Darussalam. The performance of the shrimp is summarized in Table 3.

Nates, Performance of black tiger shrimp, Table 3

| Parameter | Feed 1 | Feed 2 | Feed 3 | Feed 4 | Reference Feed |

|---|

Parameter | Feed 1 | Feed 2 | Feed 3 | Feed 4 | Reference Feed |

|---|---|---|---|---|---|

| Initial body weight (g) | 4.17 | 4.06 | 4.07 | 4.00 | 3.96 |

| Final body weight (g) | 12.76 | 12.12 | 12.05 | 11.82 | 13.25 |

| Weight gain (g/7 weeks) | 8.59 | 8.06 | 7.98 | 7.82 | 9.29 |

| Feed-conversion ratio | 2.07 | 2.30 | 2.41 | 2.25 | 1.97 |

| Survival (%) | 94.44 | 94.44 | 89.58 | 95.14 | 94.44 |

One-way variance analysis showed there was no significant difference in weight gain, feed-conversion ratio or survival among shrimp fed the different

diets. However, regression analysis showed a decrease in weight gain as PBM level was replaced by fat-extracted PBM in the diets.

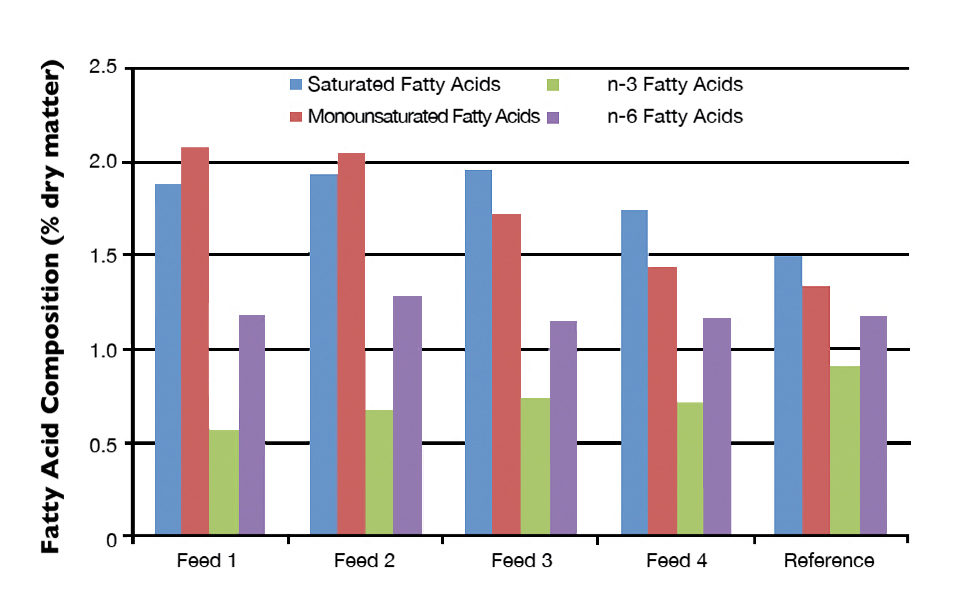

The data indicated that the residual fat, various fat components and dietary energy in PBM were valuable as nutrients for the shrimp. Carcass analysis revealed that shrimp fed PBM or fat-extracted PBM had about 25 percent higher levels of saturated fatty acids and 26 percent lower levels of n-3 fatty acids when compared to shrimp fed the reference diet (Fig. 1).

Perspectives

Supercritical carbon dioxide extraction is a novel method of extracting fat from feed ingredients. It selectively removes neutral fat and cholesterol from the ingredient, but retains phospholipids.

Residual fat, various fat components and dietary energy in PBM are valuable as nutrients to shrimp. Evaluations of PBM in diets should consider not only the residual fat and energy, but also cholesterol and phospholipids.

Dietary inclusion of PBM significantly alters the fatty acid composition of shrimp. The changes are most dramatic in the case of monounsaturated fatty acids, relatively moderate for saturated fatty acids and n-3 fatty acids, and not noticeable in the case of n-6 fatty acids.

(Editor’s Note: This article was originally published in the November/December 2011 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Sergio F. Nates, Ph.D.

Fats and Proteins Research Foundation, Inc.

801 North Fairfax Street, Suite 205

Alexandria, Virginia 22314 USA -

A. Victor Suresh, Ph.D.

Integrated Aquaculture International

Hastings, Nebraska, USA

Tagged With

Related Posts

Responsibility

A look at integrated multi-trophic aquaculture

In integrated multi-trophic aquaculture, farmers combine the cultivation of fed species such as finfish or shrimp with extractive seaweeds, aquatic plants and shellfish and other invertebrates that recapture organic and inorganic particulate nutrients for their growth.

Aquafeeds

Animal byproduct concentrates useful tools in formulation

With the market volatility of fishmeal, as well as rising sustainability concerns, the aquaculture industry is seeking sources of protein, such as animal byproduct concentrates, to substitute for fishmeal.

Aquafeeds

Animal co-product hydrolysates sources of key molecules in aquafeeds

Key molecules found in animal byproduct hydrolysates show potential for use as functional ingredients in aquaculture feeds. Animal co-product hydrolysates from slaughterhouse waste and rendered animal byproducts present a protein alternative.

Aquafeeds

Animal protein meals reduce feed costs but don’t improve shrimp performance

The authors conducted a study to determine how replacement of salmon meal with various animal protein meals in feed affected the growth performance of white shrimp.