Assessing production of channel catfish, freshwater prawns and lettuce

In aquaculture systems, cultured organisms generate waste from their defecation, by the decomposition of non-ingested food and from the contribution of microorganisms that develop around them. This is wastewater rich in nutrients that must leave the system in the form of effluents to avoid contaminating the culture medium. If not removed, some wastes can reach toxic levels for the cultured organisms, so they must be discarded or treated. The treatment of these wastes by conventional methods is usually expensive and complicated.

In an aquaponics system, these wastes are reused as liquid fertilizers to feed the plants through an integration of aquaculture with hydroponics, and a wide variety of plants – growing on different substrates – are able to absorb, through their roots, the nutrients that come from aquatic cultures. Plants act as a natural filter by reducing the concentration of extra nutrients and cleaning the water, which can then be re-integrated and recirculated into the aquatic species component system (recirculating aquaculture system, RAS).

Aquaponics creates a mini-ecosystem between plants and aquatic organisms that benefit and support each other to survive and grow. It has become an ideal alternative because it moves nutrient-rich water from the aquaculture component and uses it as a nutrient for plants in the hydroponics component. In our study, we evaluated the performance of channel catfish and freshwater prawns and three varieties of lettuce – American, Romaine and Rose – in a research aquaponics system.

Study setup

The study was conducted at the Fishing Nautical Nucleus (NNP) of the National Learning Institute (INA) located in the central canton of the Province of Puntarenas. Carried out under greenhouse conditions, the only water used as liquid fertilizer for the plants came from 1 cubic meter tanks where freshwater prawns (Macrobrachium rosenbergii) and channel catfish (Ictalurus punctatus) were cultured.

The aquaponics system used in the study included a greenhouse with a translucent plastic roof and walls lined with white anti-aphid mesh. The plastic, square culture tanks (1.15 x 0.95 m, 0.93 m deep) were raised by 1 meter with a wooden platform.

An intensive farming system was used, with the catfish juveniles stocked at a density of 100 per cubic meter and a weight of 0.5 grams, while for the freshwater prawns postlarvae (PL; 0.003 g), two stockings were done one month apart at a density of 100/cubic meters each, for a total stocking of 200 PL per cubic meter. The catfish and prawns were cultured for 85 days with constant aeration and continuous water exchange and fed ad libitum with commercial feed for tilapia and marine shrimp, respectively. At the end of the study, the catfish and the prawns were harvested and weighed and returned to the culture system.

After 40 days of culture, the lettuce plants were planted with the recirculation system in operation. In total, 63 plants were planted in an area of 5 square meters for a density of 12.6 lettuces per square meter. The different lettuce varieties were planted interspersed in seven rows of three plants each. The substrate bed was 20 cm deep and the water flowed at 15 cm deep at a flow rate of 200 mL per second.

Various water quality parameters, including temperature, pH and dissolved oxygen, were monitored weekly. Dissolved oxygen levels were maintained at saturation through constant aeration from the continuously operating blower and diffuser hoses.

The plant project lasted for 45 days and the catfish and prawn project for 85 days of culture. The plants were harvested and measured with a tape measure. The aquatic organisms were weighed and measured individually. An evaluation of weekly growth (grams per week), final biomass (grams per cubic meter), feeding rate (grams of feed per cubic meter X days) and feed conversion (grams feed per grams of biomass) was made for the catfish and prawns.

Results

A closed recirculation system was developed and operated where wastewater from the catfish and prawns was removed from the bottom with daily water exchanges. Wastewater went to a collection tank and then to a biological filtration tank with bio balls as a substrate for bacteria.

The nitrifying bacteria convert the ammoniacal compounds from the wastewater to less toxic forms for the catfish and prawns and nutritious ones for the plants in the form of nitrates. The cleanest and most nutritious water was transferred to the channel with a substrate bed (limestone) used as a hydroponic system where the lettuces were planted. This water was then collected in a tank and pumped back to the aquaculture tanks to close the recirculation system.

The greenhouse aquaponic system, with a plastic roof and fine anti-aphid mesh walls, maintained on average a relative humidity of 65 percent and an ambient temperature of 35 degrees-C during the day. Dissolved oxygen levels were close to saturation (from 6.9 to 10.1 with an average of 8.7 mg/L) during the study period, and water temperature fluctuated between 27.0 and 31.0 degrees-C, with the highest values 32.4 degrees-C measured during the afternoons. All water quality parameters measured were within the values reported as adequate for the species tested.

Table 1 shows the final production results for the 85-day study period for the catfish and prawns

The survival rate for the prawns was 86 percent and for the catfish it was 96 percent, reflecting the appropriate operation of the aquaponic system to support both species. Prawn survival was related to the installation of a mesh that served as a natural refuge.

Valverde, Aquaponics-Costa Rica, Table 1

| Parameter | PW Prawns | Catfish |

|---|

Parameter | PW Prawns | Catfish |

|---|---|---|

| Initial weight (g) | 0.003 | 0.5 |

| Number stocked | 200 | 100 |

| Culture period (days) | 85 | 85 |

| Number harvested | 172 | 96 |

| Survival (%) | 86 | 96 |

| Mean final weight (g) | 1.8 ± 1.5 | 9.9 ± 4.2 |

| Growth (g/week) | 0.15 | 0.82 |

| Biomass (g) | 309.6 | 950 |

| Feed amount (g) | 324 | 1,600 |

| Feed rate (g/m3 x day) | 3.8 | 18.8 |

| FCR | 1.0 | 1.7 |

The final average weights after 85 days of culture was 9.9 grams for the catfish and 1.8 grams for the prawns. Both can be considered low due to the high stocking densities used. In the case of prawns, it could represent a high-density nursery stage for juveniles – resulting in higher survivals because of the controlled culture environment – that can later be transferred to other culture systems and stocked at lower densities for grow-out.

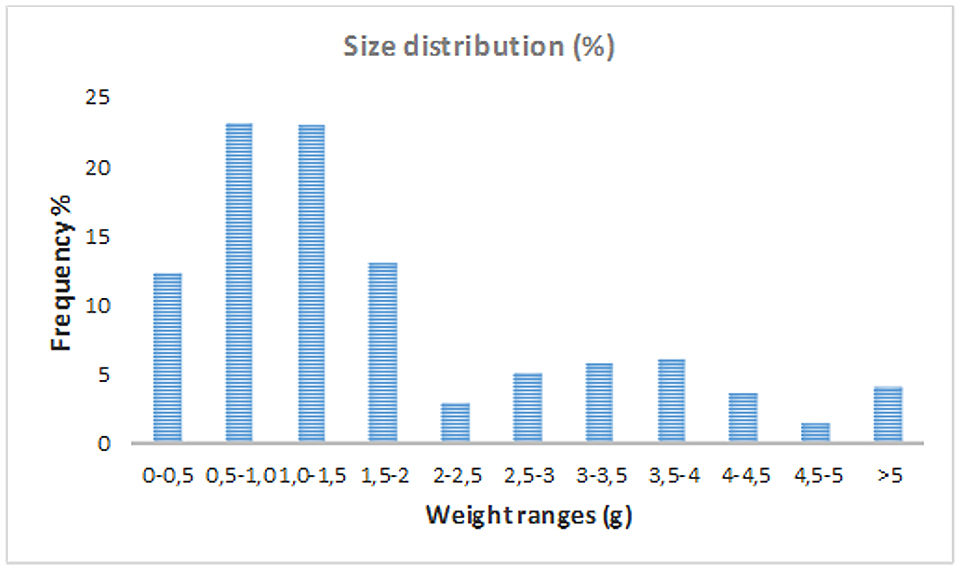

Fig. 1 shows prawn size distribution, and the normal distribution of two different populations is evident. The largest prawns are those that were stocked first and had final weights from 2 grams to over 5 grams. The small prawns are from the population stocked a month later and had final weights from less than 0.5 grams and up to 2 grams. The size disparity increased as the prawns grow larger.

The growth rates were 0.15 and 0.82 grams per week for prawns and catfish, respectively. In pond culture, these species reach an average of 20 grams for prawns and 600 grams for catfish after 7 months (210 days) of culture. This means that the growth is 0.67 grams/week and 20.0 grams/week respectively. Therefore, we consider the growth rate for both species extremely low in our aquaponics system.

The biomasses reached during the growing period were 310 grams and 950 grams for the prawns and the catfish, respectively. During the study period, the prawns were fed to satiety with 324 grams and the catfish were fed 1,600 grams of feed. The resulting feed conversion were 1:1 and 1.7:1, respectively; both of these values are within standards for pond culture of these species, so feeding was adequate in our experimental system.

Valverde, Aquaponics-Costa Rica, Table 2

| Parameter | Prawn tank | Catfish tank | Aquaculture tank drainage | Plant drainage |

|---|

Parameter | Prawn tank | Catfish tank | Aquaculture tank drainage | Plant drainage |

|---|---|---|---|---|

| Iron (mg/L) | 0.00 ± 0.00 | 0.03 ± 0.02 | 0.00 ± 0.00 | 0.04 ± 0.06 |

| Nitrate (mg/L) | 2.75 ± 0.21 | 4.60 ± 0.99 | 4.45 ± 2.05 | 4.00 ± 1.98 |

| Nitrite (mg/L) | 0.05 ± 0.00 | 0.05 ± 0.00 | 0.04 ± 0.01 | 0.05 ± 0.00 |

| TAN (mg/L) | 0.00 ± 0.00 | 0.06 ± 0.06 | 0.03 ± 0.01 | 0.05 ± 0.06 |

| Chlorides (mg/L) | 0.09 ± 0.04 | 0.12 ± 0.02 | 0.08 ± 0.00 | 0.09 ± 0.00 |

| Alkalinity (mg/L CaCO3) | 110 ± 7 | 112 ± 9 | 110 ± 2 | 117 ± 25 |

| Hardness (mg/L Ca CO3) | 125 ± 15 | 174 ± 53 | 142 ± 6 | 165 ± 11 |

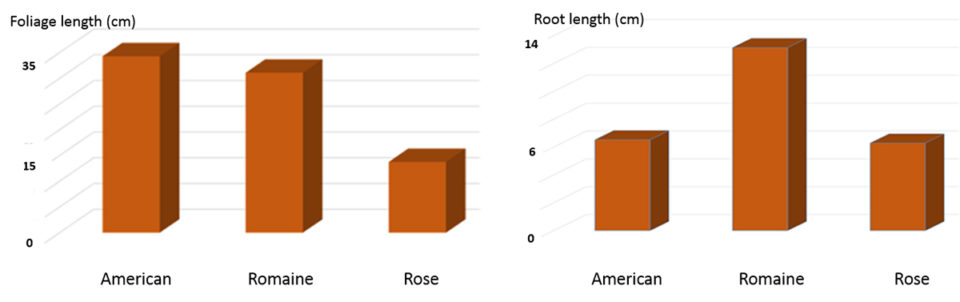

Fig. 2 shows the yields of the three lettuce varieties in terms of foliage and root lengths. Our results show significantly lower performance in these variables for the Rose variety versus the American and Romaine varieties. Of the number of leaves counted in this variety, 30 percent were dead or very deteriorated. The Romaine variety had significantly greater root development than the American variety, while there were no significant differences in foliage height or number of leaves between these varieties.

References available from first author.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

José Valverde

Núcleo Náutico Pesquero

Instituto Nacional de Aprendizaje (INA)

Puntarenas, Costa Rica -

Marco Acosta

Núcleo Náutico Pesquero

Instituto Nacional de Aprendizaje (INA)

Puntarenas, Costa Rica -

Marvin Torres

Dirección de Investigaciones

Sede Central, UTN

Costa Rica

Tagged With

Related Posts

Intelligence

An engineer’s design for a classroom aquaculture-aquaponics system

An aquaponics teaching system was designed, built and operated by students at the University of Arizona, integrating its operation and management into the educational curriculum. This engineering design will require minimum maintenance and will last years.

Innovation & Investment

Innovative aquaponics system frugal with fluids

As global demand for food rises, the focus on water resources will intensify. In Berlin, a four-year research project is demonstrating the feasibility of aquaponics, which can drastically cut water inputs.

Intelligence

Young aquaponics, aquaculture company gets big boost

Fluid Farms, an aquaponics produce grower in Maine, leans on multi-trophic aquaculture to provide nutrients for its plants. The company is now selling its hybrid striped bass to the local market and, armed with a $50,000 innovation prize that will fund a new heating system, is expanding its horizons.

Responsibility

Aquaponic system produces red drum, saltwater vegetable species

A project in Florida is studying the feasibility of a marine aquaponic system containing red drum and two native saltwater species. Water that exits the plant raceways is filtered and recirculated to the fish tanks. In tests, sea purslane grew rapidly, while saltwort took almost four months to adapt. The fish exhibited high survival and achieved a feed-conversion ratio of 1.2.