GenetiRate hopes to prove it’s wise to sort your eggs before they hatch

Technology that had its genesis in a search for an obesity treatment could end up helping fish grow faster – without requiring more feed.

Automated egg-sorting technology developed by from Tucson, Ariz.-based GenetiRate is being tested by prominent aquaculture companies and showing promising results.

Explaining GenetiRate’s approach, Benjamin Renquist, the company’s president, pointed out that some people eat a lot but don’t gain weight, a consequence of fundamental differences.

“Some people’s cells, to stay alive, require a lot of energy. Some people’s cells, to stay alive, require very little energy. And the same is true with fish,” he said.

To measure that difference in aquatic species, GenetiRate’s patented method determines the level of the biochemical NADH (nicotinamide adenine dinucleotide) present in an egg or via biopsy in a mature living organism. NADH is central to metabolism. If more is present, the metabolic rate is higher.

That higher metabolism can manifest itself in different ways, something Renquist discovered when he worked with zebra fish in an attempt to identify genes that could cause weight loss. He found that zebra fish eggs that resulted in heavier fish were those with higher initial levels of NADH.

“That increase in NADH production that we were measuring was actually an increase in growth rate,” Renquist said, adding that he licensed the technology from the University of Arizona, where he did the research that lead to the discovery. GentiRate then developed products based on that technology.

If the NADH reading is done on an egg or embryo, this picking of metabolic winners and losers happens before variations in feed can have an effect. So, the test detects fundamental individual differences and can be used to improve broodstock by, for instance, eliminating eggs that have a lower growth potential.

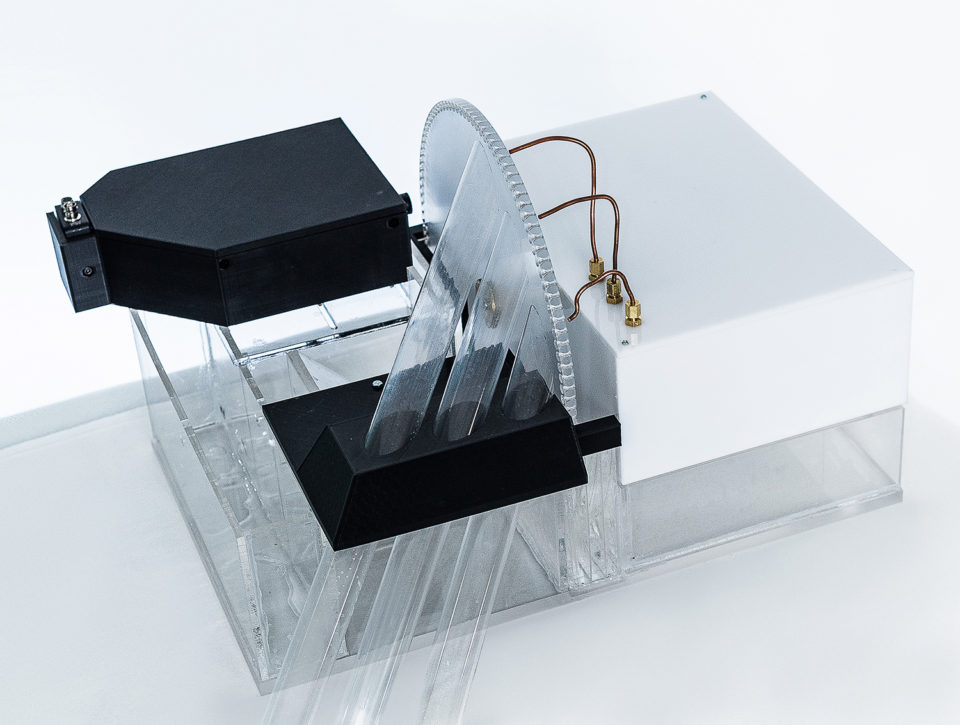

In practice, this is done by tagging eggs with a fluorescent dye that reacts with NADH, with more dye sticking to those embryos with more NADH. Then within a machine, a green laser sweeps briefly across the eggs. The dye glows orange, a visual signal that the human eye can see in the right light.

Based on this laser-induced indicator, the system identifies embryos that have higher growth rates. This information can be used as desired, such as sorting and selecting better performing individuals for breeding.

To see what’s possible with this approach, consider that in the 1920s, it took 16 weeks to get a newly hatched chicken to market. By the end of the century, that time had been cut in half, as had the feed needed, according to data from the U.S. National Chicken Council. That is a model cited by Carsten Krome, a managing partner in Alimentos Ventures and co-founder of the Hatch aquaculture accelerator. The company has invested in GentiRate, in part because of the poultry industry’s example.

“GenetiRate’s technology is jump-starting this development for the aquaculture sector and has the potential to get aquaculture the same results in a fraction of that time,” Krome said.

Robins McIntosh, executive VP of Bangkok-based Charoen Pokphand Foods, said his company is considering GentiRate’s technology as a tool for determining the feed conversion ratio. FCR is difficult to assess, according to McIntosh but is important since feed can be a significant part of the cost in raising an aquatic species to maturity. A lower FCR can translate into a better bottom line.

“The system works and does differentiate metabolic rates at early fish stages,” McIntosh said of GentiRate’s products, hinting about plans to put the technology without specifying how his company might use the tool.

He noted, however, that the technology does require significant manpower in some applications. The problem is the plating of embryos, an issue Renquist said has been addressed by automating the analysis process for salmonids. Similar mechanization is on the way for tilapia and shrimp.

GentiRate plans to sell sorters and is looking at other applications of its methodology. Users will pay on a per test basis, Renquist said, and there could eventually be installations in many different locations.

“This test can be applied in any aquatic species. It can then be applied to land-based species,” he said. “It actually applies across all species.”

Follow the Advocate on Twitter @GAA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Hank Hogan

Hank Hogan is a freelance writer based in Reno, Nevada, who covers science and technology. His work has appeared in publications ranging from Boy’s Life to New Scientist.

Tagged With

Related Posts

Innovation & Investment

Fish sorting technology firm aims to modernize farms

With a novel in-water sorting technology in the works, Agam says automating labor-intensive tasks on fish farms can improve accuracy and harvest yield.

Innovation & Investment

One fish, two fish: Counting technology nets funding for Canadian engineering firm

XperCount, aka the “magic bucket,” uses optics and photonics to deliver 95 percent accurate count of microorganisms, such as fish or shrimp larvae, in just seconds.

Innovation & Investment

If it’s broken, fix it: Startup takes on shrimp industry in India

A serial tech entrepreneur and a shrimp trader want to be Amazon for India’s shrimp farming industry. An accelerator program half a world away has brought them closer to their goals.

Innovation & Investment

JALA engineering innovation for Indonesian shrimp farmers

A company in Indonesia hopes the vast network of shrimp farms throughout the country will adopt its IoT device, particularly when they’re on the go.