Drying, chemical disinfection kills unwanted and desirable organisms alike

In pond aquaculture, managers should attempt to prevent disease and other unwanted organisms from surviving in the bottoms of empty ponds between crops. They also should make efforts to prevent unwanted organisms from entering when ponds are refilled with water for the next crop.

Dry-out, toxicants, liming compounds

The traditional way of destroying organisms in pond bottoms is thorough dry-out for one to two weeks or longer. This procedure is effective in areas where the bottoms will completely dry, but in ponds where the water table is near the surface or seepage enters from adjacent ponds, puddles and wet areas remain. Moreover, during rainy periods, it is not possible to dry pond bottoms well.

Wild fish in puddles can be destroyed with rotenone or other fish toxicants. However, of greater concern are parasites and disease organisms and their vectors that can survive in wet areas to infect the next crop. It is common to treat wet areas or sometimes entire pond bottoms with burnt lime, calcium oxide; or hydrated lime, calcium hydroxide. The objective of lime treatment is to raise pH to 11 or 12 to kill unwanted organisms.

Trials on small plots of empty pond bottoms showed that 100 g/m2 of lime raises soil pH to about 10, and a recent laboratory study found that lime treatment of 300-500 g/m2 caused soil pH to rise to 11.

Few pond managers use lime rates even as high as 100 g/m2, and in many cases, liming of wet areas probably does not have the expected effect. To assure a pH high enough to kill unwanted organisms, the treatment rate should be at least 200 g/m2 for burnt lime and 300 g/m2 for hydrated lime. Following application, lime is transformed to soil carbonate by reaction with carbon dioxide, and pH falls to 8.5 or less within a few days.

Calcium hypochlorite

An option for disinfecting wet areas is to apply calcium hypochlorite, also known as high-test hypochlorite (HTH). Treatment rates of 25-50 g/m2 usually are applied, but laboratory studies suggest that rates three or four times greater are needed to cause a reduction in the abundance of bacteria in wet soil.

Water for refilling ponds often is held in reservoirs for several days before being introduced into ponds. This practice possibly eliminates free viral particles, but not their vectors. Filtering water through fine-mesh filters removes wild fish and shrimp, microcrustaceans and other common vectors, but smaller organisms pass through the filters. Biocides can be applied to reservoirs or ponds in lieu of filtration, or both treatments can be used.

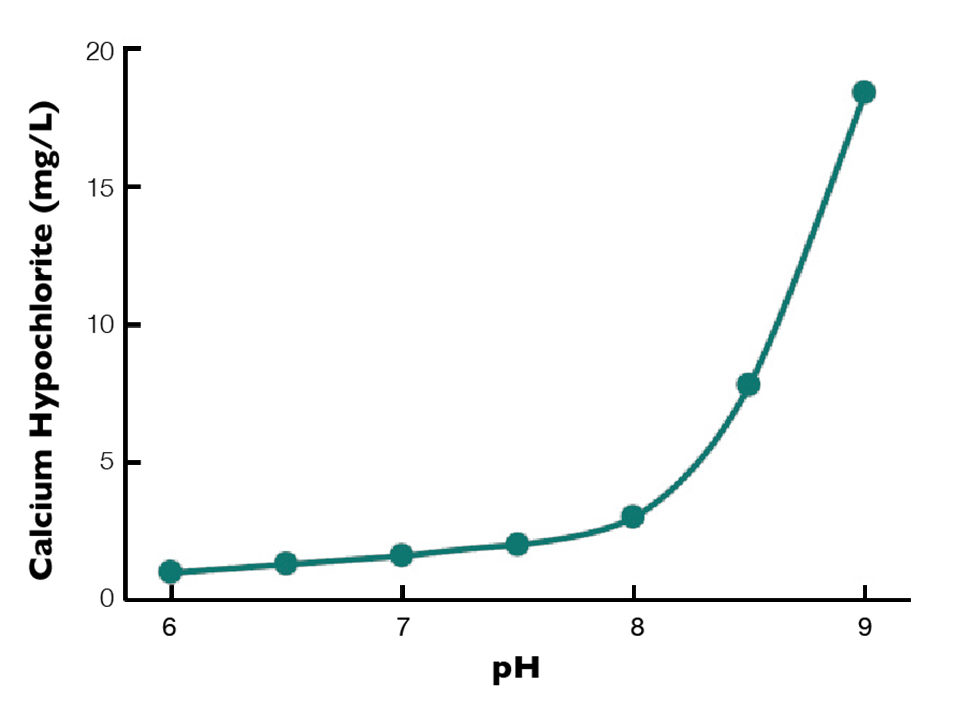

Calcium hypochlorite can be used to disinfect water for refilling ponds. The disinfecting power of HTH treatments depends upon the hypochlorous acid:hypochlorite ion ratio, which decreases as pH rises. The HTH doses necessary to provide 1 mg/L of hypochlorous acid at different pH values are provided in Figure 1.

Water for aquaculture ponds usually has a pH around 8, and studies have shown that the effective HTH concentration for disinfection usually is 20-30 mg/L. Thus, disinfection of pond water with HTH is quite expensive.

Hypochlorous acid and hypochlorite concentrations quickly decline – usually within a few days following treatment. Chlorine compounds are reduced to non-toxic chloride ions through reactions with organic substances and the effects of sunlight.

Chlorine gas

Because of the high cost of HTH, some farms have used chlorine gas as a disinfectant. At the pH of waters in aquaculture systems, chlorine gas is transformed to hypochlorous acid and hypochlorite ions.

Chlorine is a highly poisonous gas, and the transport and handling of containers of chlorine are fraught with danger. Major lethal accidents have resulted from transporting chlorine gas for industrial purposes. Its use at aquaculture facilities is not recommended.

Insecticides

Often referred to as DDVP, dichlorovos is an organophosphorus insecticide with the chemical name 2,2-dichlorovinyl dimethyl phosphate. This compound provides a cheaper alternative to HTH for disinfection of water in aquaculture ponds. It is effective at much lower concentrations than HTH, with treatment rates of 1-3 mg/L effective in destroying disease vectors.

Because DDVP is an insecticide, its use in aquaculture tends to alarm environmentalists and other people. However, within three or four days after application, DDVP concentrations decline to an undetectable level in water. In reality, DDVP is a safer compound than HTH for disinfecting pond waters.

DDVP often is marketed in Asia as pondvos or crusticide for use in shrimp ponds. It is used in reservoirs before water is transferred to ponds or in ponds treated after refilling but before they are stocked with postlarvae. In shrimp ponds, several months pass between treatment with DDVP and harvest, and there is no likelihood of DDVP contamination of shrimp harvested from ponds previously treated with this compound.

Toxicity considerations

Fish toxicants, lime, HTH and DDVP can be toxic to aquatic organisms if accidentally spilled into natural waters, so they should be stored and used in a responsible manner. Fish toxicants are not especially toxic to humans, but workers should take precautions to minimize contact with them. Lime is caustic, and can burn the skin and cause serious eye injury – even permanent blindness.

Workers should wear protective clothing including eye protection and gloves. Workers also should be provided respiratory protection to avoid inhaling HTH and DDVP. HTH should never be put into highly acidic water with pH below 4, because chlorine gas will be generated. Nevertheless, lime, HTH and DDVP can be used safely if proper precautions are taken.

Pond preparation after disinfection

Drying of bottom soils and chemical disinfection of bottom soil and water kills unwanted and desirable organisms alike. After drying and chemical treatment, benthic and plankton organisms are in low abundance.

Postlarval shrimp or fingerling fish should not be stocked until populations of natural food organisms have re-established. Fertilization of pond bottoms with organic matter immediately before refilling and application of urea and triplesuperphosphate to the water during and after refilling – but before stocking – hasten the development of benthos and plankton.

(Editor’s Note: This article was originally published in the November/December 2012 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Claude E. Boyd, Ph.D.

Department of Fisheries

and Allied Aquacultures

Auburn University

Auburn, Alabama 36849 USA

Tagged With

Related Posts

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Health & Welfare

AHPN inferences based on behavior of vibrio bacteria

Vibrio parahaemolyticus, a strain of which is the cause of acute hepatopancreatic necrosis (AHPN), has both virulent and benign strains. This strain colonizes the stomachs of shrimp by the formation of a biofilm, which protects it from antibiotics and other potential treatments.

Innovation & Investment

Acoustic control improves feeding productivity at shrimp farms

In systems recently developed for shrimp farms, passive acoustic-based technology enables sensor-based control of multiple automatic feeders. Improved growth and feed conversion have been recorded at commercial farms using the technology.

Responsibility

Appraising pond liners for shrimp culture

The use of plastic-lined ponds by shrimp farmers can significantly improve production efficiency, support more production cycles per year, and higher mechanical aeration rates and stocking densities. The capital cost of lining ponds can be very significant, so a thorough feasibility analysis is recommended when considering this production tool.