Summary of FAO/WHO discussion paper on chlorinated water

Both industry representatives and environmentalists have voiced concerns regarding the production of hazardous byproducts when chlorine is used for disinfection in the fish processing industry. The principal concerns are associated with the uptake of chlorine from wash water by fishery products, and the uptake or formation of disinfection byproducts in fish resulting from the use of chlorinated water. The Food and Agriculture Organization (FAO) and the World Health Organization (WHO) recently addressed these issues through a discussion paper on the use of chlorinated water, which is briefly summarized here.

At the 1998 meeting of the Codex Fish and Fishery Products Committee (CCFFP) in Norway, the use of chlorine as a disinfectant to reduce the microbial load of raw fishery products such as prawns and shrimp was discussed. Views expressed there indicated the use of chlorinated water was common practice in the fish processing sector, but significant differences in that use existed between countries.

Concerns were expressed about toxic residues and possible risks to public health that may result from byproducts arising from the use of chlorine water in washing fish and fishery products. Further concerns addressed an insufficient knowledge of current industry practices in different countries, and there was a broad consensus that additional information was needed. Current Codex recommendations allow up to 10 milligrams per liter chlorine in water that comes in contact with fishery products, and up to 100 milligrams per liter in water for cleaning equipment and facilities.

Technical document

The Codex Committee on Food Hygiene requested that FAO/WHO prepare a technical paper on residual levels of chlorine in products such as frozen prawns and shrimp, when washed with chlorinated water, and on recommended levels used in processing. This document was prepared during the Session of the Joint FAO/WHO Food Standards Programme in Norway last June.

It discusses several topics, including forms and concentrations of chlorine used in fish processing (and elsewhere in the food industry); reactions of aqueous chlorine with fishery products; reactions of chlorine in drinking water, with poultry wash water, and with compounds present in fish; risk assessment of the use of chlorine in fish processing; sensory changes due to the use of chlorine; and chlorine and microbiological control.

Concentrations of chlorine in fish processing

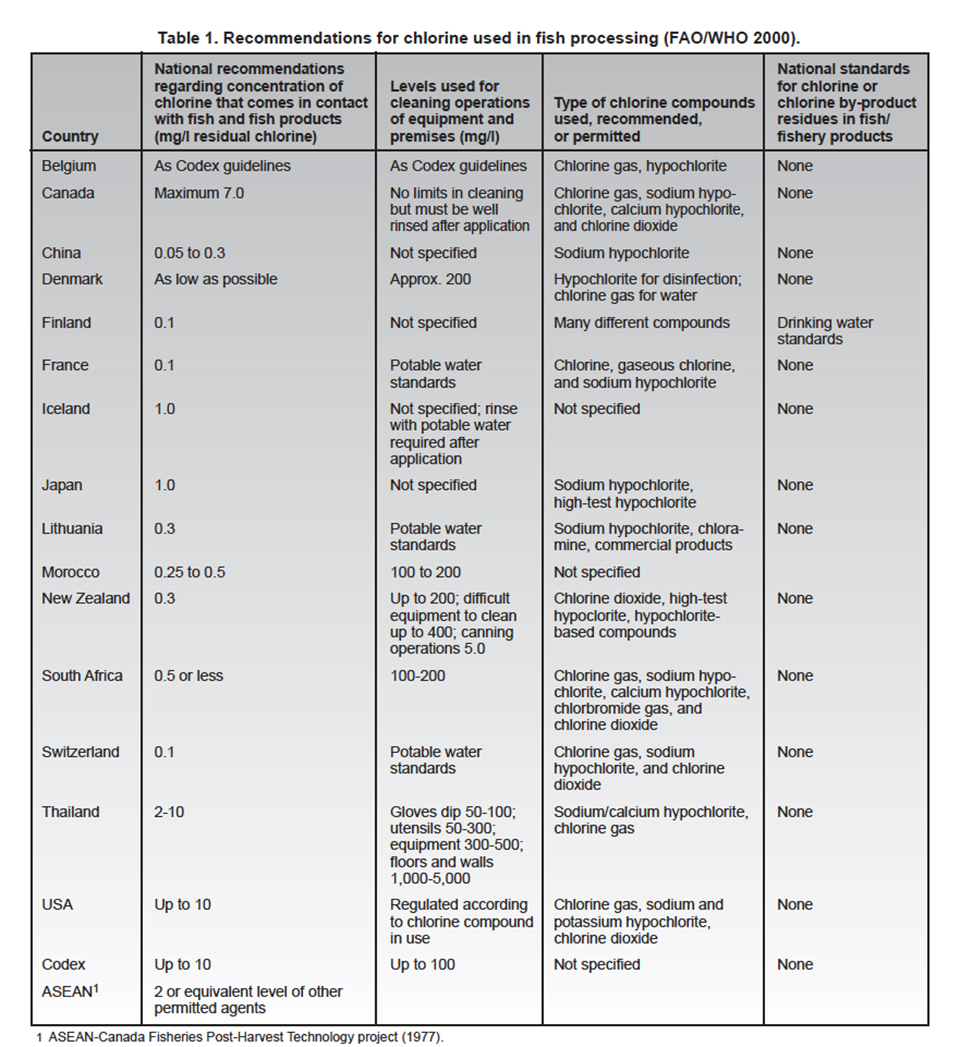

Many countries provided data (summarized in Table 1) on the use of chlorine in their fish processing sectors. In general, specific national standards or recommendations for residual levels of chlorine in water that comes in contact with fish or fishery products during processing and preparation do not exist. In most instances, the recommendations of the WHO Drinking Water Guidelines are usually followed – residual levels of between 0.2 and 0.5 milligrams per liter in the water distribution system.

Levels of chlorine in water used for washing equipment and facilities (floors, walls, etc.) vary according to the level of surface contamination. Where high levels of chlorine are used, a final rinse with potable water is the usual industrial practice. It is very unlikely that consumers of fishery products will be exposed to any risk from the use of chlorine in cleaning and washing equipment and facilities provided good manufacturing practices are followed.

The current Codex Recommended International Code of Practice for Shrimps and Prawns (CAC/RCP/17-1978 Codex Alimentarius Volume B, 2nd Edition, FAO/WHO, 1984) and the Codex Recommended International Code of Practice for Fresh Fish CAC/RCP/9-1976 (FAO/WHO, 1983) include the following statements under the sections that cover handling of fish at sea:

It has been established in the fish processing industry that the injection of chlorine into a supply of cold water used for general wash-up helps to control microbial contamination. The fishing vessels involved in handling or processing large quantities of fish or shrimp might gain considerably in hygiene by having chlorine introduced into water lines. Chlorine dosage should be around 10 ppm during normal use and 100 ppm of residual concentration during clean-up.

Some national authorities have adopted this Codex value and recognize that up to 10 milligrams per liter active chlorine in fish processing water and ice that contacts seafood is generally recognized as safe (GRAS). The use of chlorine up to this concentration is based on a history of safe use and accepted industry practice over many years. During the preparation of this document no data or evidence was found that suggests that there are public health problems associated with this practice.

Conclusions of discussion paper

It is very unlikely that consumers of fishery products will be exposed to any risk from the use of chlorine in cleaning and washing equipment and facilities, provided good manufacturing practices are followed.

Consumer exposure to chlorine byproducts from the consumption of fish that has been exposed to water treated with up to 10 milligrams per liter chlorine is likely to be very low. Consumer exposure primarily results from chlorinated process water, and even if low levels are present in raw fishery products, most of these will be lost on cooking. The organic material present in the edible tissues of fish and fishery products is subject to oxidation and chlorination reactions when exposed to aqueous chlorine solutions.

Limited data is available regarding the toxicity of such chlororganic compounds. Soon-to-be-published experimental results show no mutagenic activity in extracts of fish fillets treated with water containing 20 milligrams per liter chlorine. While additional work in this area is recommended, the current scientific evidence does not warrant changing the recommended Codex levels of 10 milligrams per liter for water in direct contact with fishery products.

Chlorination of water used in fish processing and maintenance of distribution systems are critical points in preventing contamination by waterborne pathogens and in reducing the incidence of cross-contamination. More information is needed on the levels and reactivity of chlorine used in the seafood industry, the identity and toxicity of reaction products, and the level of these compounds to which consumers are exposed before coming to further conclusions about the risks of using chlorine in fish processing.

(Editor’s Note: This article was originally published in the October 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

Tagged With

Related Posts

Responsibility

Chlorine an effective disinfectant in aquaculture

Ponds should be fertilized a few days after chlorine application to encourage the regrowth of natural food organisms before introducing postlarvae.

Intelligence

Chlorine dioxide offers seafood treatment alternative to aqueous chlorine

Chlorine dioxide effectively reduces microorganisms on seafood and could be used as a processing treatment to improve shelf life and product safety.

Health & Welfare

A perspective on shrimp larviculture and liquid larval diets

A prominent shrimp farm and hatchery in Venezuela has tested microparticles, microencapsulated particles and liquid larval diets.

Health & Welfare

A study of Zoea-2 Syndrome in hatcheries in India, part 2

Indian shrimp hatcheries have experienced larval mortality in the zoea-2 stage, with molt deterioration and resulting in heavy mortality. Authors considered biotic and abiotic factors. Part 2 describes results of their study.