Antinutritional factors limit use of plant feedstuffs

Antinutritional factors within plant feedstuffs is a major factor that limits plant use at high dietary inclusion levels in aquafeeds.

There is limited information on the quality characteristics and performance of shrimp grow-out diets manufactured in the United States.

Antinutritional factors within plant feedstuffs is a major factor that limits plant use at high dietary inclusion levels in aquafeeds.

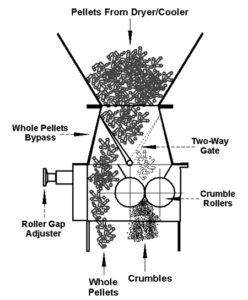

In the crumbling process of pelleting, whole pellets are crushed to produce starter diets used to feed different stages of shrimp in their early development.

Shrimp postlarvae diets can be fed entirely artificial, but the best growth rates are obtained when feeds include artemia or enriched artemia.

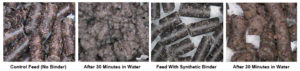

Synthetic and natural binders that provide increased water stability are often used without consideration of the final dry or wet pellet texture of the shrimp feed.

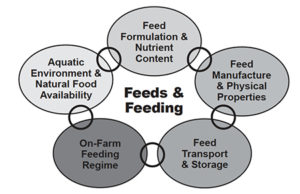

Formulated shrimp feed represents about 50 percent of production costs, but even more if the feed is wasted because of poor quality.

Select pelleting equipment that best fits plant layout from vendors that specialize in drying and cooling, rather than buying complete “packages” from one supplier.

Maturation diets for shrimp broodstock often include fresh food organisms like squid, bloodworms and fish, which is labor-intensive and involves quality and safety issues.

Knowledge of the fatty acid nutrition requirements in Pacific white shrimp, an economically important penaeid for shrimp farming in the Americas, is limited.

Cottonseed meal is a lower-cost protein alternative to soybean meal, but its use in commercial shrimp feeds may be limited because it contains gossypol.

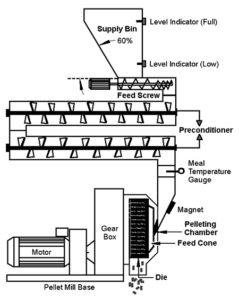

When feed pellets exit the die of a pelleting mill, they are moved to a post-pellet cooker or post-conditioner, where they are allowed to set prior to cooling or drying.

To produce a high-quality feed with specific nutritional and physical characteristics, feed equipment processes must often be modified and optimized.

Successful weaning of marine fish larvae from live feeds onto dry diets is a demanding process that requires hard work, patience and experience.

With decreasing prices and increasing raw-material costs, efforts to reduce shrimp feed costs and improve management top the agenda for most farmers.

Pelleting mills, where finely ground and conditioned meal are mechanically pressed through a die, produce cost-effective, high-density, water-stable shrimp feeds.

Penaeid shrimp are unable to bio-synthesize cholesterol, which is widely accepted as an essential nutrient for these crustaceans.