Microbial protein FeedKind® could help provide ‘high-quality seafood’ while reducing environmental pressures

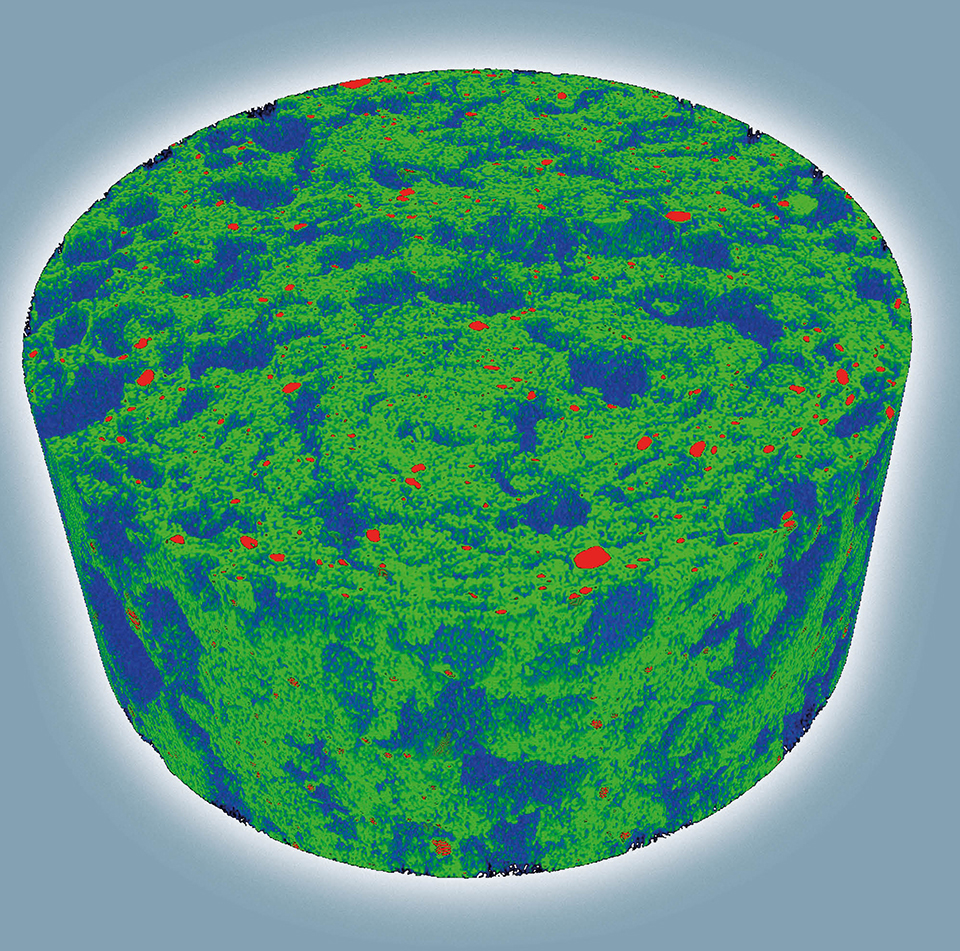

Calysseo, a joint venture between global animal nutrition leader Adisseo and protein innovator Calysta, has launched the world’s first industrial-scale FeedKind® facility to produce a new sustainable functional protein that does not use animal or plant ingredients in its production. The facility will produce 20,000 metric tons of FeedKind® Aqua protein annually from the facility in Chongqing, China.

“This is a significant milestone as we move towards more sustainable forms of making food,” said Jean-Marc Dublanc, CEO of Adisseo. “Calysseo and FeedKind® offer a world first, a newly available sustainable, nutritious, non-GMO protein that offers significant health benefits over other feed ingredients, such as improved gut health and improved immune response.”

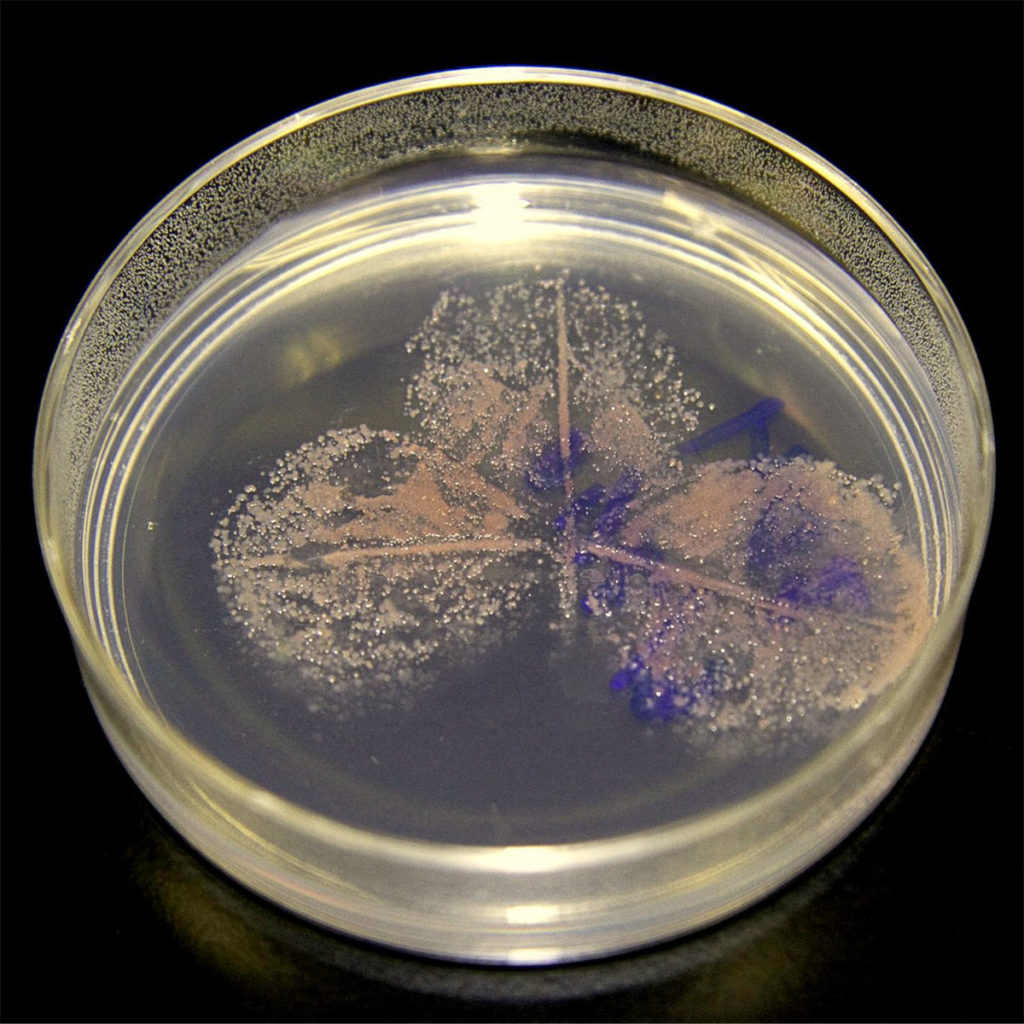

FeedKind® is part of a family of ingredients developed by Calysta, which harness the power of a naturally occurring microorganism that consumes low-cost, land-free carbon sources, converting it into a nutritionally rich protein for food and feed applications.

The microbial protein is produced via a natural fermentation that does not use arable land, animal or plant matter, and uses very little water in its production. Initially, production will be available for use in China, the world’s largest aquaculture market.

“We have a long-running commitment to improving the security and sustainability of the feed ingredient market and Calysseo fulfills a significant part of that pledge,” said Dublanc. “We will provide Chinese customers with a reliable, domestically available supply of protein that meets their specific needs; produced in China for China.”

The strategic partnership between Adisseo and Calysta will directly address one of the most important opportunities in aquaculture: to provide high-quality seafood without adding extra pressure to the environment.

Over several years, FeedKind® has been validated after extensive trials across several popular aquaculture species, including seabass, bream and salmon. Thailand’s Kasetsart University, Thailand, recently found distinct benefits for shrimp, reporting that FeedKind® promotes strong, healthy growth, while also helping activate shrimp’s immune response to Vibrio, the causative agent of Early Mortality Syndrome.

It’s anticipated that FeedKind® will help to reduce pressure on wild fisheries. If substituted for conventional sources of protein, 100,000 tons of FeedKind® could mean that between approximately 420,000 to 450,000 tons of wild-caught fish could be saved. Used instead of vegetable proteins, the same quantity of FeedKind® could free up as much as 535 km2 of land and would save 9 billion litres of water.

“Cellular agriculture, where protein is grown in a controlled environment, is key to helping the world meet its future food needs,” said Alan Shaw, Ph.D., co-founder, CEO and president of Calysta. “Today will go down in history as a hugely significant moment in the development and delivery of new, sustainable sources of protein to meet growing, global demand.”

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

Tagged With

Related Posts

Aquafeeds

NovoNutrients secures funding to scale up microbial meal production

NovoNutrients, a microbial meal producer using industrial waste as an energy source, has secured $9 million in equity to scale production.

Aquafeeds

KnipBio partners with ICM to scale-up production of single-cell protein for aquaculture

Leader in fermentation, bio-refining technology a “great strategic fit” for single-cell protein aquafeed ingredient maker transitioning from R&D labs to commercial production.

Aquafeeds

In vitro protein digestibility of a microbial-enhanced protein for juvenile white shrimp

A microbial-enhanced protein for juvenile Pacific white shrimp showed higher levels of hydrolysable protein and better digestibility than soybean meal.

Aquafeeds

Alternative feed ingredients support continued aquaculture expansion

Identifying sources for essential macro- and micronutrients is important, as well as understanding how best to manufacture feed to required physical specifications when using these new raw materials.