Calculations for large and small bodies of water

Managers often must treat aquaculture ponds with fertilizers, liming materials, osmoregulatory enhancers, coagulants, oxidants or algicides. Dosages of these materials should be calculated accurately to avoid waste, assure efficacy and prevent possible damage to the culture species or culture environment. Various chemical treatments also may be applied to other types of holding and grow-out units.

Pond treatments usually are made on the basis of pond area or chemical concentration desired. The areas and average depths of ponds are typically determined during construction. However, while pond areas are usually remembered, average depths often are forgotten. Moreover, the depths of ponds change over time in response to sediment accumulation and fluctuate according to practices for replacing seepage and evaporation.

Pond volume, depth

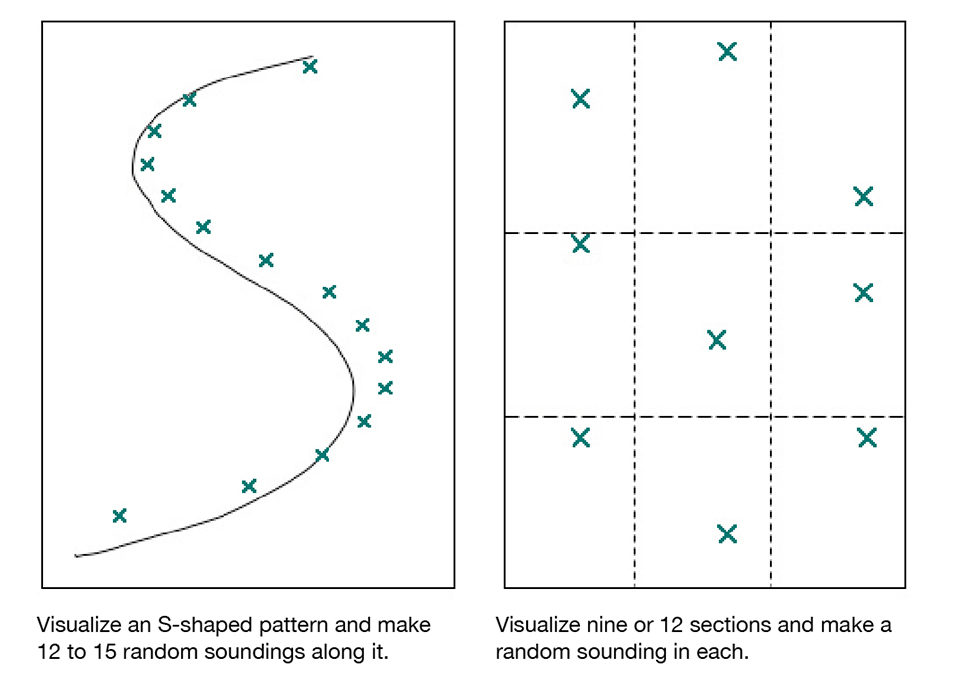

Standard surveying techniques can accurately estimate the volume of a pond. However, it is far simpler – and sufficiently accurate – to obtain pond depth by averaging soundings made at many places in a pond (Fig. 1). Soundings should be taken when the pond water level is equal to the elevation of the overflow structure intake.

Ponds usually are constructed so that a 15- to 30-cm decline in surface water elevation does not appreciably decrease surface area. At times when the pond is not full, the average depth can be estimated as the full depth minus the vertical distance from the intake of the overflow structure to the water surface. Volume is calculated as average depth multiplied by surface area.

Treatment products

Some products used for pond treatments are solid, particulate materials, such as agricultural limestone, lime, traditional fertilizers, copper sulfate crystals and potassium permanganate. Others are liquids, some examples of which are fluid fertilizers, chelated copper solutions, formalin, calcium hypochlorite solutions and molasses.

Pond treatment products seldom contain 100 percent of the active ingredient. Liming materials are applied on the basis of their neutralizing value or percentage calcium carbonate equivalence – the neutralizing value of different liming products can range from less than 75 percent to more than 150 percent. The active ingredients of fertilizers are their nutrients, especially nitrogen and phosphorus.

Although many farmers still apply fertilizers on a quantity-per-hectare basis, a growing trend is to apply a specific quantity of nutrients per hectare or dose of fertilizer calculated to increase the concentration of nutrients in the pond water by a specific amount. Copper sulfate can be applied to provide a certain concentration of copper, and copper sulfate contains only 25 percent of the active ingredient copper. Crushed rock salt (sodium chloride) is applied to ponds to raise the chloride concentration to a specific level to combat nitrite toxicity. This product is seldom less than 97 percent pure, and pure sodium chloride is nearly 61 percent chloride. Thus, the active ingredient content of the salt applied to ponds is about 58 to 59 percent.

The specific gravity of liquid products used in aquaculture often differs from the specific gravity of water, which has a specific gravity of 1. Fluid fertilizer preparations usually have a specific gravity around 1.4, meaning they are 1.4 times denser than water. A product with a specific gravity of 1.0 and 50 percent active ingredient would contain 0.5 kg active ingredient per liter, but a product with specific gravity of 1.4 and the same percentage of the active ingredient would contain 0.7 kg per liter.

Calculations for large ponds

In calculating the amounts of substances to apply to ponds, one must adjust for the percentage of the active ingredients in solid products. Adjustments for both active ingredient content and specific gravity must be made for liquid products. Equations are provided in Table 1 for use in estimating pond treatment rates. An example is shown below.

Boyd, Equations for calculating chemical treatment, Table 1

| Chemical Form | Treatment Type | Equation Metric* | Equation English** |

|---|

Chemical Form | Treatment Type | Equation Metric* | Equation English** |

|---|---|---|---|

| 1. Solid | Weight/area | A x R A.I./100 | A x R A.I./100 |

| 2. Solid | Weight/volume | (A x D x C) x 10 A.I./100 | (A x D x C) x 2.71 (A.I./100) |

| 3. Liquid | Volume/volume | (A x D x C) x 10 (A.I./100) x S.G. | (A x D x C) x 2.71 (A.I./100) x S.G. |

*A = area (ha), D = average depth (m), R = treatment rate for active ingredient (kg/ha), C = treatment concentration of active ingredient (g/m3 or mg/l),

A.I. = percentage active ingredient, S.G. = specific gravity (lb/gal),

10 = factor for converting g/m3 to kg/ha-m.

** A = area (acres), D = average depth (ft), R = treatment rate for active

ingredient (lb/acre), C = treatment concentration of active ingredient

(ppm or g/m3), A.I. = percentage active ingredient, S.G. = specific gravity (lb/gal),

2.71 = factor for converting ppm to lb/acre-ft.

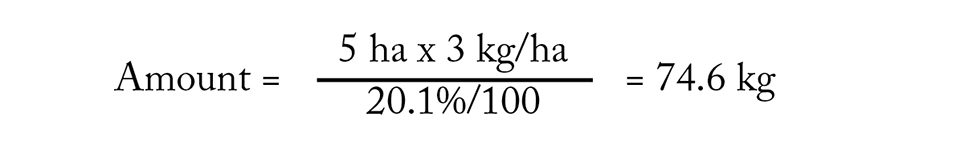

Example: What is the amount of triple superphosphate fertilizer (46 percent phosphorus pentoxide, 20 percent phosphorus) needed to provide a treatment rate of 3 kg phosphorus/ha in a 5-hectare pond? Use the metric Equation 1 from Table 1.

Liming materials can be applied to bottoms of empty ponds or to the surfaces of full ponds. In either case, the liming material should be spread uniformly over the entire pond area. Other pond treatments usually are made to ponds filled with water. Fertilizers and other products should be dissolved and mixed uniformly in the water for best results. Most granular materials settle to the pond bottom before completely dissolving if broadcast over pond surfaces.

Liquids that are denser than water settle to the bottom without completely dissolving in the water column if splashed directly over the pond surface. Fertilizers, other granular materials and liquids should be dissolved or made into a slurry in a container of pond water before applying.

The resulting solution or slurry can be splashed over the surface, released into the turbulence caused by the motor while a boat is driven in a zigzag pattern over the pond or sprayed over the pond surface from the edges or a boat. The operation of mechanical aerators in ponds following applications of pond treatments encourages mixing of the product throughout the water volume.

Calculations for small ponds

Equations are provided in Table 2 for the calculation of the amounts of substances necessary for treating small ponds or other fish production units. The basic equations for calculating volumes of regular-shaped vessels for fish culture follow: square, V = L2 D; rectangular, V = L x W x D; circular, V = pi x r2 x D, where V = volume (m3 or ft3), L = length (m or ft), W = width (m or ft), D = water depth (m or ft) and r = radius or one-half of diameter (m or ft). An example is provided.

Boyd, Equations for calculating chemical treatment amounts, Table 2

| Chemical Form | Treatment Type | Equation Metric* | Equation English** |

|---|

Chemical Form | Treatment Type | Equation Metric* | Equation English** |

|---|---|---|---|

| 1. Solid | Weight/area | A x R A.I./100 | A x R A.I./100 |

| 2. Solid | Weight/volume | V x C A.I./100 | (V x C) x 0.001 (A.I./100) x S.G. |

* A = area (m2), R = treatment rate for active ingredient (g/m2),

C = treatment concentration for active ingredient (g/m3 or mg/l),

A.I. = percentage active ingredient, S.G. = specific gravity (oz/fluid oz).

** A = area (ft2), R = treatment rate for active ingredient (lb/ft2),

C = treatment concentration of active ingredient (ppm or g/m3),

A.I. = percentage active ingredient, S.G. = specific gravity (oz/fluid oz),

0.001 = factor for converting ppm to oz/ft3.

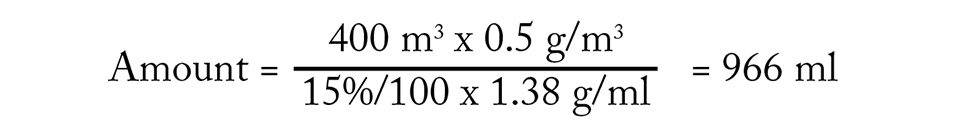

Example: What is the amount of liquid fertilizer (15 percent phosphorus, specific gravity 1.38) needed to provide a treatment rate of 0.5 mg phosphorus per liter in a 400-cubic-meter pond? Use the metric equation 3 from Table 2.

(Editor’s Note: This article was originally published in the May/June 2009 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Claude E. Boyd, Ph.D.

Department of Fisheries and Allied Aquacultures

Auburn University

Alabama 36849 USA

Tagged With

Related Posts

Health & Welfare

AHPN inferences based on behavior of vibrio bacteria

Vibrio parahaemolyticus, a strain of which is the cause of acute hepatopancreatic necrosis (AHPN), has both virulent and benign strains. This strain colonizes the stomachs of shrimp by the formation of a biofilm, which protects it from antibiotics and other potential treatments.

Health & Welfare

Algae shows promise as alternative DHA source in rainbow trout diets

A growth trial in Canada evaluated the use of algae biomass to increase the concentration of long-chain polyunsaturated fatty acids in the tissues of rainbow trout.

Responsibility

Assessing culture potential of red emperor snapper in New Caledonia

The red emperor snapper, known as “pouatte” in New Caledonia, is valuable throughout its broad geographic range and a highly valued food fish locally. Declining wild catches and market demand have provided the incentive to carry out technical feasibility studies to determine its commercial aquaculture potential.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.