In the last year, use of Ocean Harvest compostable bags has replaced approximately 56 miles of plastic packaging

When Erin Adams, Eric Oransky and Willy Leathers opened their oyster farm, Maine Ocean Farms, in Freeport in 2017, the trio began searching for an alternative to the plastic mesh packaging traditionally used to contain harvested oysters.

But they came up emptyhanded. Still determined to reduce packaging pollution, they located an Austrian-based manufacturer who could create biodegradable, compostable bags made from beechwood cellulose fiber. In 2020, Adams co-founded Ocean Farm Supply in Brunswick, Maine, to distribute these products.

“When we were harvesting oysters, we didn’t want to put this premium product into a plastic bag, but we couldn’t find any alternatives on the market that suited our needs,” said Adams, the company’s CEO. “We created Ocean Harvest bags to provide a solution and share it with others in the industry. Our goal is to remove single-use plastics from shellfish harvesting and distribution.”

Adams estimated that in 2019, the sale of 88 million pounds of clams, mussels and oysters generated 1,400 miles of mesh pollution.

“That’s a conservative estimate, if every piece of shellfish was put into a plastic bag,” she said.

‘Plug-and-play’ shrimp farm inventor out to prove that Shrimpbox is more than just a neat idea

Primarily targeting the produce industry, Austrian manufacturer Packnatur® was happy to use its fiber to create a similar but stronger mesh specifically for shellfish like oysters, which often have sharp edges. The fiber, extracted from beechwood grown in Austrian forests, is spun into a strong, all-natural yarn that decomposes in a typical home compost in just 12 weeks.

Ocean Harvest bags cost $0.29 per foot while plastic harvest bags cost between $0.16 and $0.20 per foot. The biodegradable bags are sold in 140-meter sleeves and customers cut them to the lengths they need and seal each end after the bags are filled. Pre-cut and custom-length bags are also available.

To date, the company has sole distribution rights in the United States and Canada, and has gained around 60 customers, half in New England and the other half stretching from Alaska to the Southeast. Customer feedback has been extremely positive, Adams said.

“We hear that our product works well on retail counters and for customers who supply directly to consumers,” she said. “People appreciate that the bags are home-compostable and we have many repeat customers.”

Her goal is to ultimately bring the weaving machinery to the United States and use fiber from Maine trees to manufacture the bags. But that’s 10 to 15 years away. “Right now, we’re just trying to build the market, and it makes the most sense to import the bags,” she said.

The aquaculture industry is so forward-thinking, and we’re hoping it will embrace this solution.

In the last year, use of Ocean Harvest bags has replaced approximately 56 miles of plastic packaging and Adams said the company is just scratching the surface with plastic-free solutions.

“The three of us want to leave things a little better than the way we found them,” she added. “We’re encouraged that a number of businesses have sustainability targets and are actively looking for bags with a composting element. Ideally, our bags end up in compost, but even if they don’t, their production still results in lower emissions than plastic or cotton bags, making Ocean Harvest bags a smarter, more sustainable choice. The aquaculture industry is so forward-thinking, and we’re hoping it will embrace this solution.”

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Lauren Kramer

Vancouver-based correspondent Lauren Kramer has written about the seafood industry for the past 15 years.

Tagged With

Related Posts

Responsibility

Composting of seafood processing sludge

Study evaluates if controlling maturation stage during seafood sludge composting through turning improves the process in comparison to static composting.

Responsibility

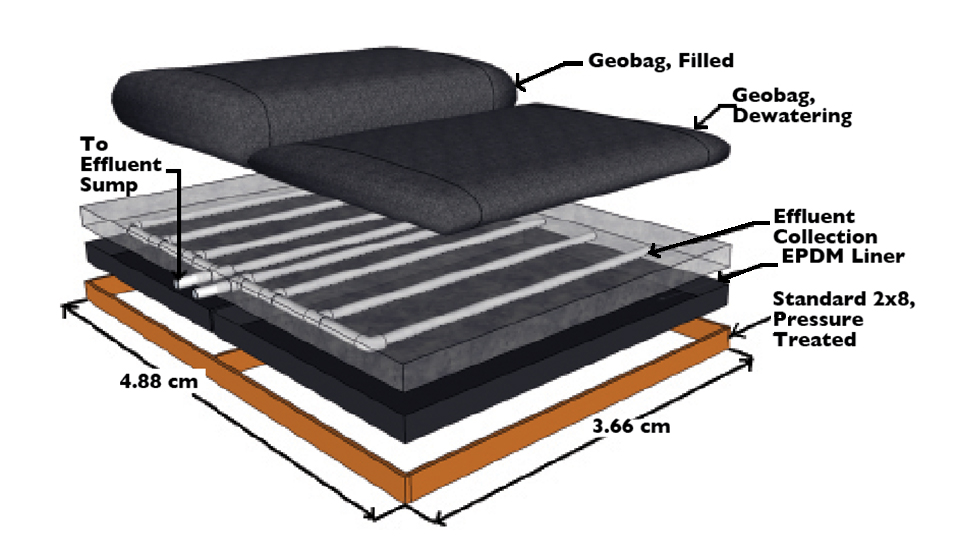

Geotextile bags enhance effluent management in demo aquaculture system

One promising new technology for dewatering aquaculture solid waste is the use of geotextile bags: porous, sealed tubular containers constructed of high-strength, woven polyethylene material.

Responsibility

Nutrient recycling and circular economies can support sustainable intensification of aquaculture, part 1

With nutrient recycling, aquaculture can contribute sustainably toward the nutritional requirements of billions of people over the next century.

Responsibility

Sludge report: Finding value in Norway’s aquaculture waste

Bioretur converts aquaculture waste, or sludge, into fertilizer as demand for “circular economy” technologies grows.