African catfish juveniles perform well, but benefits depend on carbon source, C:N ratio

Biofloc technology is a water quality management strategy that requires adding a carbon source – such as sugars, glycerol or complex carbohydrates – that stimulates heterotrophic bacterial growth, which converts otherwise toxic nitrogenous waste into biomass.

At the same time, the bacteria also produce substances that cause suspended solids – such as debris, microalgae, zooplankton and others – to aggregate into larger particles called “bioflocs.” Due to their larger size, this increases the chances of their consumption by various aquatic animals. The subsequently higher water turbidity can appear to farmers as being unhealthy or actually dangerous to the animals.

However, bioflocs maintain water quality while potentially providing constant nutrition. The consumption of these bioflocs, and in turn the ability to promote animal growth, is largely based on the fish’s ability to collect and consume these particles. For example, suspension-feeding fish are better adapted to consume smaller bioflocs than carnivorous species, such as African catfish (Clarias gariepinus).

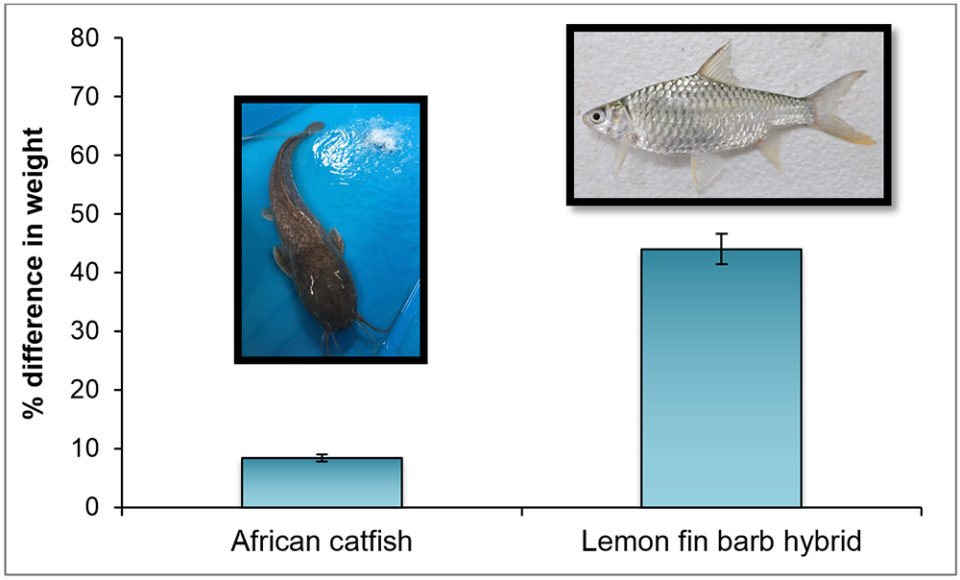

This limited ability of C. gariepinus has been observed in several studies and more recently when we compared their growth performance in clear water versus that of the more omnivorous lemon fin barb hybrids (LFBH) (male Hypsibarbus wetmorei x female Barboides gonionotus) in a biofloc-based system (Fig. 1). This was likely due to LFBH effectively consuming bioflocs based on observing full intestines when bioflocs were the only available source of food.

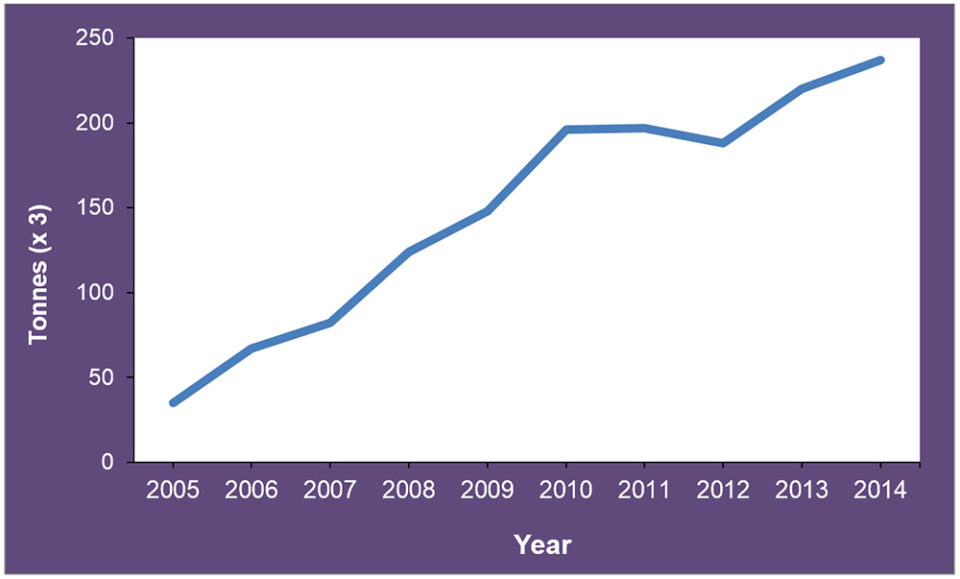

Nevertheless, in a series of experiments, our laboratory showed that C. gariepinus juveniles greatly benefited from biofloc-based systems, which may help produce better quality and more disease resistant seed. This should help expand the African catfish farming industry, which has already grown more than five-fold in the past decade (Fig. 2). However, the benefits of biofloc technology (BFT) to this carnivorous species largely depend on the carbon source and the ratio to nitrogen.

Carbon to nitrogen ratios

Generally, carbon-to-nitrogen (C/N) ratios of 10 to 20 are recommended in biofloc-based systems, with higher ratios increasing biofloc production. Higher biofloc production is not always favorable due to the need for more aeration to support higher microbial respiration rates and to keep bioflocs suspended. This can not only increase operating costs, but also any disruptions to air flow can result in the loss of an entire crop. Moreover, because C. gariepinus are inefficient collectors and consumers of bioflocs, these can accumulate to excessive amounts.

Our laboratory has shown that using glycerol to create C/N ratios of 10, 15 or 20 caused no growth improvement in C. gariepinus juveniles. Nevertheless, a zero-exchange system was effectively created under high stocking densities and, moreover, C/N ratios of 15 and 20 improved the resistance of C. gariepinus to the bacterial pathogen Aeromonas hydrophila. This was encouraging, because this pathogen can cause substantial economic losses in the catfish industry. However, a C/N ratio of 15 appeared to be the best ratio based on maintaining water quality, minimizing excessive biofloc production and protecting the catfish from bacterial infection.

Carbon source

Simple sugars, glycerol and complex carbohydrates are commonly used carbon sources for BFT, but in many countries that farm C. gariepinus, complex carbohydrates can be much cheaper. However, this source is less soluble than simple sugars and thus cannot be quickly utilized by bacteria-producing flocs. This can consequently delay the removal of ammonia leading to deteriorated water quality. Despite C. gariepinus being relatively tolerant to elevated nitrogenous waste, this was believed to cause juvenile mass mortalities under a laboratory setting because ammonia production was not matched by bacterial assimilation into bioflocs. Therefore, among these tested carbon sources of sucrose, and at least for the initial set up of BFT, glycerol or sugars appear to be more appropriate.

Improving water solubility of complex carbohydrates

One of the ways to improve the water solubility of complex carbohydrates, and therefore the potential for better bacterial utilization, is by pre-treating with microorganisms such as probiotics. These organisms secrete digestive enzymes capable of degrading insoluble components of carbohydrates like cellulose.

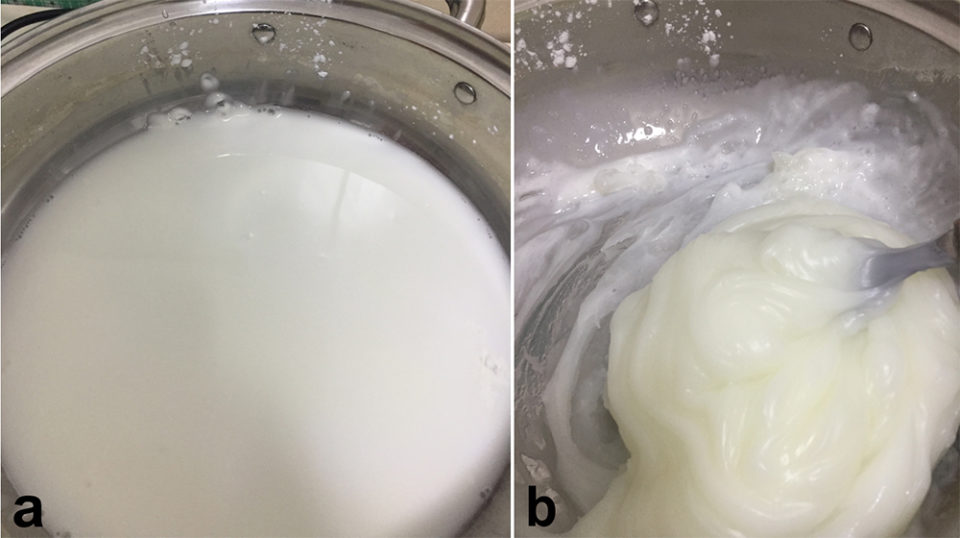

Our research recently found that fermenting rice bran with Bacillus lichenformis and B. megaterium substantially enhanced water solubility by 96 percent, and in contrast to untreated rice bran, effectively created a zero-exchange system. In addition, the fermented rice bran significantly improved the growth of C. gariepinus, and although a probiotic effect may have occurred, it may also indicate some consumption of biofloc. This can be better understood by using gelatinized starch to achieve higher water solubility (Fig. 3) without the presence of probiotics.

Perspectives

A major reason for developing BFT was to maintain water quality that would provide enhanced biosecurity and reduce water use. While this can be beneficial for any species, only those that could tolerate high turbidity were believed to be candidates. Another potential benefit was a growth promoting effect of BFT in some species, due to better water quality and/or the constant availability of nutritious bioflocs. This growth benefit was believed to not apply to more carnivorous species, but for C. gariepinus because there were indications of more energy, we observed higher resistance to pathogenic bacteria and, in the case of fermented rice bran, higher growth. Based on our results, we encourage additional, similar research into other carnivorous fish species to help support further sustainable growth of the aquaculture industry.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Nicholas Romano, Ph.D.

Aquaculture/Fisheries Center

University of Arkansas at Pine Bluff

1200 North University Drive

Pine Bluff 71601AR USA

-

Akeem Babatunde Dauda, M.S.

Department of Aquaculture, Faculty of Agriculture

Universiti Putra Malaysia

43400, Serdang, Selangor, Malaysia; and

Department of Fisheries and Aquaculture

Federal University

Dutsin-Ma PMB 5001, Dutsin-Ma Katsina State, Nigeria

Tagged With

Related Posts

Intelligence

Biofloc technology production promising in temperate zones

A study was conducted to assess the feasibility to grow Channel catfish (Ictalurus punctatus) in an outdoor biofloc system during winter in a temperate zone. High biomasses of market-size channel catfish were successfully maintained through the winter with high survival and in good condition in both treatments.

Health & Welfare

Evaluating biofloc technology for intensive culture of fathead minnows

A study tested the use of biofloc technology to improve the productivity of the fathead minnow (Pimephales promelas) a commercially important baitfish in North America.

Health & Welfare

Biofloc technology: Possible prevention for shrimp diseases

Facing emerging viral problems and rising energy costs, the use of biofloc technology in biosecure systems offers an answer for sustainable shrimp aquaculture. The main attributes of biofloc systems in reducing disease risk include the fact that low water exchange improves pathogen exclusion.

Responsibility

Optimizing tilapia biofloc technology systems, part 1

Chambo Fisheries, the world’s largest tilapia biofloc tank farm and the largest tank farm in Africa, has a multi-cohort, sequential, continuous production schedule.