Biofloc systems deliver high productivity with sustainability

Biofloc technology has become a popular technology in the farming of Pacific white shrimp (Litopenaeus vannamei). The basic technology was developed by Dr. Yoram Avnimelech in Israel and initially implemented commercially in Belize by Belize Aquaculture. It also has been applied with success in shrimp farming in Indonesia and Australia. The combination of two technologies, partial harvesting and biofloc, has been studied in northern Sumatra, Indonesia.

Biofloc technology

Biofloc is defined as macroaggregates composed of diatoms, macroalgae, fecal pellets, exoskeleton, remains of dead organisms, bacteria and invertebrates. It is possible this microbial protein has a higher availability than feed protein.

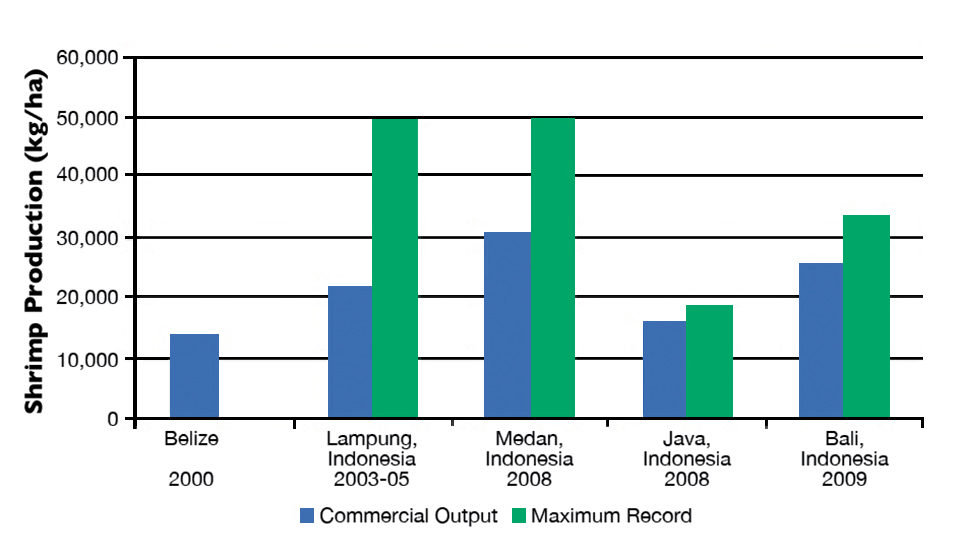

The basic requirements for biofloc system operation include high stocking density with 130-150 PL10/m2 and high aeration of 28 to 32 hp/ha with correct paddlewheel position in ponds. Ponds must be lined with concrete or high-density polyethylene (HDPE), and pelleted grain and molasses are added to the culture water. Shrimp production of 20-25 metric tons per hectare (MT/ha) per crop is normal for biofloc systems. A maximum production of nearly 50 MT/ha was achieved in small ponds in Indonesia.

A crucial factor in the system is the control of bioflocs in ponds during operation. In raceways, settable solids wastes are removed outside the raceway. However, in large ponds, paddlewheel aerators need to be positioned to concentrate solid waste at the pond center for draining or other area for siphoning out. The suspended bioflocs are maintained at less than 15 mL/L during operation. The carbon:nitrogen ratio is controlled and kept over 15:1 by adjusting molasses, grain and feed inputs.

Commercial interest

Commercial interest in biofloc technology is threefold, for bioflocs provide high productivity, low feed-conversion ratios (FCRs) and a stable culture environment. Also, with emerging viral problems and rising costs for energy, biofloc technology appears to be an answer for sustainable production at lower cost.

The technology has not only been applied at commercial shrimp growout farms, but also in super-intensive raceways to produce more than 9 kg shrimp/m3. The raceway applications have supported nursery and grow-out to shrimp broodstock rearing and selection of family lines. Presently, a number of studies by major universities and private companies are using biofloc as a protein source in shrimp and fish feeds.

Applications

The number of shrimp farms currently using biofloc technology is not known, but some prominent examples are Belize Aquaculture, Ltd., in Belize and P.T. Central Pertiwi Bahari in Indonesia. The success or failure of the technology is mainly due to the degree of understanding of basic concepts of the technology in commercial application.

Belize Aquaculture was the first commercial farm to use biofloc technology successfully. Its production of 13.5 MT shrimp/ha was quite an achievement at the time. The Belize technology was applied initially in Indonesia at C.P. Indonesia (now P.T. Central Pertiwi Bahari, C.P. Indonesia), which achieved average production over 20 MT/ha in commercial 0.5-ha lined ponds. Research trials reached 50 mt/ha.

The technology combined with partial harvest was repeated in Medan, Indonesia, with better results. During 2008 and 2009, biofloc technology was used in Java and Bali successfully. In Indonesia, biosecurity protocols were incorporated within the technology.

Most Indonesian shrimp farmers are interested in biofloc technology, but with some reservations, as a number of projects have failed due to incomplete understanding of the technology. For example, the correct number and position of paddlewheel aerators used in ponds are essential.

The main objectives for paddlewheel aerators are to keep bioflocs in suspension. This can be achieved with informal aeration, but with no mechanism to concentrate solid waste for removal, high levels of suspended biofloc biomass can lead to deterioration of pond water quality. Eventually, this results in premature harvests, if not total crop failure.

Advantages, disadvantages

The advantages of biofloc technology include very high biosecurity. To date, white spot syndrome virus has not been a factor in the systems. Production and carrying capacity are typically 5 to 10 percent higher than in typical culture systems, with zero water exchange. Shrimp grow larger and reflect feed-conversion rations between 1.0 to 1.3. Production costs can be 15 to 20 percent lower.

The disadvantages include high energy inputs for aerators. Power failures over an hour in duration can be critical. Biofloc ponds must be lined. The more advanced technology also demands a greater need to properly train technicians.

Taw, Performance of shrimp farms, Table 1

| Pond | Karang Asem A2 | Karang Asem A3 | Karang Asem B1 | Karang Asem B2 | Karang Asem B3 | Karang Asem C1 | Karang Asem C2 | Karang Asem C3 | Singaraja B3 | Singaraja B4 |

|---|

Pond | Karang Asem A2 | Karang Asem A3 | Karang Asem B1 | Karang Asem B2 | Karang Asem B3 | Karang Asem C1 | Karang Asem C2 | Karang Asem C3 | Singaraja B3 | Singaraja B4 |

|---|---|---|---|---|---|---|---|---|---|---|

| Pond size | 2,600 m2 | 2,500 m2 | 2,000 m2 | 2,000 m2 | 2,000 m2 | 600 m2 | 600 m2 | 600 m2 | 2,500 m2 | 2,500 m2 |

| Stocking density | 129/m2 | 134/m2 | 167/m2 | 167/m2 | 167/m2 | 152/m2 | 152/m2 | 152/m2 | 152/m2 | 152/m2 |

| Days of culture | 125 | 125 | 126 | 91* | 125 | 147 | 135 | 147 | 147 | 147 |

| Survival (%) | 91 | 84 | 93 | 62 | 85 | 92 | 89 | 91 | 85 | 81 |

| Average body weight | 20.57 | 20.12 | 18.18 | 12.19 | 18.55 | 24.15 | 21.14 | 24.27 | 24.39 | 24.39 |

| Feed-conversion ratio | 1.3 | 1.42 | 1.36 | 1.45 | 1.44 | 1.61 | 1.52 | 1.58 | 1.63 | 1.59 |

| Harvest/pond | 6.23 mt | 5.69 mt | 5.64 mt | 2.49 mt | 5.25 mt | 2.02 mt | 1.72 mt | 1.94 mt | 6.30 mt | 6.00 mt |

| Harvest/ha | 23.97 mt | 22.78 mt | 28.22 mt | 12.46 mt | 26.23 mt | 33.64 mt | 28.75 mt | 32.36 mt | 25.21 mt | 24.02 mt |

Growing interest

Due to success stories in Indonesia and the United States, many shrimp farmers are interested in biofloc technology. The Indonesia Department of Fisheries and shrimp associations are arranging a three-day training workshop on biofloc in Indonesia. Dr. Yoram Avnimelech was invited to lead the workshop in April.

In China, a number of shrimp farmers are also interested. Their fully HDPE-lined, plastic-covered shrimp growout ponds with high-density culture are ideal for the technology. The author is currently advising shrimp farms with HDPE-lined intensive culture ponds in Central America on biofloc systems. A group from Brazil is running commercial biofloc trials.

Malaysia is currently initiating a 1,000-ha integrated intensive shrimp-farming project at Setiu, Terengganu by Blue Archipelago. The company also plans to use the technology.

(Editor’s Note: This article was originally published in the May/June 2010 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Nyan Taw, Ph.D.

General Manager

Senior Technical Advisor

Blue Archipelago BDH

T3-9, KPMG Tower, 8 First Avenue

Persiaran Bandar Utama, 47800

Petaling Jaya, Selangor, Malaysia

Tagged With

Related Posts

Aquafeeds

Biofloc and clear-water RAS systems: a comparison

This study compared two types of indoor, shrimp culture systems: clear-water RAS and biofloc systems. Clearwater RAS had the edge in water quality, but shrimp in the biofloc treatment had a higher feed conversion ratio.

Aquafeeds

Biofloc consumption by Pacific white shrimp postlarvae

The stable isotopes technique with δ13C and δ15N can be used to determine the relevance of different food sources to shrimp feeding during the pre-nursery phase of Litopenaeus vannamei culture. During this trial, different types of commercial feed, microalgae, Artemia sp. nauplii and bioflocs were used as food sources.

Aquafeeds

Biofloc systems viable for tilapia production

Well-designed and managed biofloc technology systems are a viable alternative for production of various species like tilapia, to increase feed efficiency by lowering aquafeed protein requirements and to help reduce or eliminate effluent discharges.

Health & Welfare

Biofloc technology holds potential for carnivorous fish species

Juvenile carnivorous African catfish performed well in biofloc-based systems, which could help produce better quality and more disease-resistant seed of this important aquaculture species and support the expansion of African catfish farming industry.