Fixed Phage’s biotechnology breakthrough targeting EMS, SRS

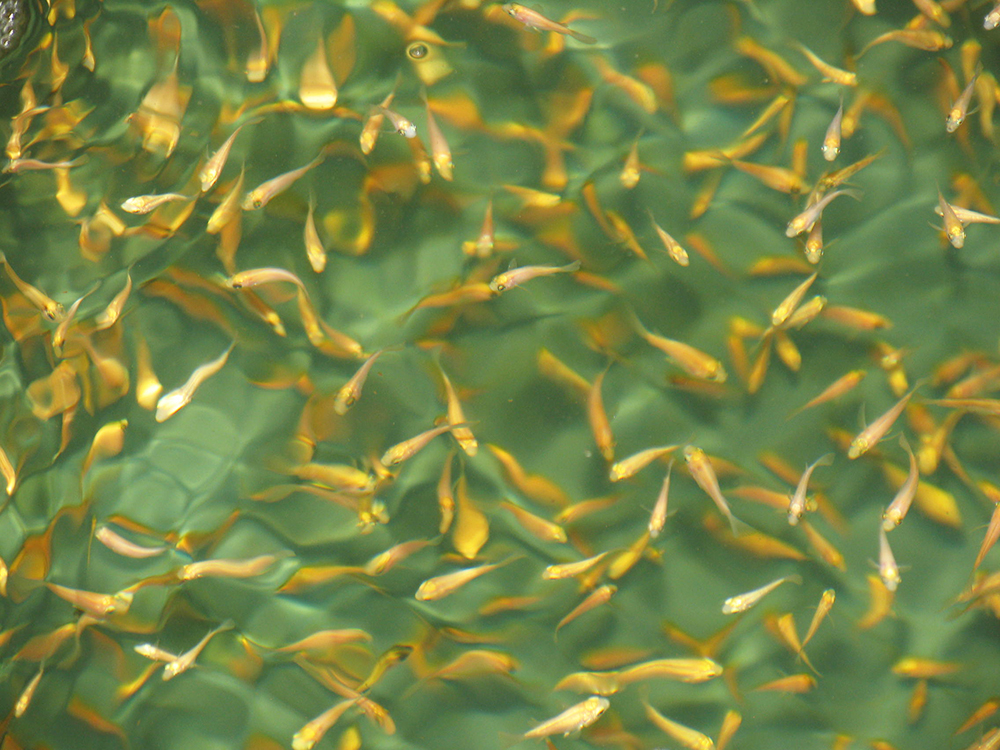

Scottish biotech firm is training the most abundant microorganisms on the planet – bacteriophages, or viruses – to kill specific, harmful bacteria that cause some of the world’s most destructive aquaculture diseases.

Fixed Phage is bottling the prowess of bacteriophages to deploy them against the farmed shrimp disease EMS (Early Mortality Syndrome) and farmed salmon disease SRS (Salmon Rickettsial Syndrome), both caused by bacterial infections. Commercial Director Athol Haas presented this potentially game-changing technology at the Global Aquaculture Alliance’s GOAL conference last month in Dublin, Ireland.

Haas told the Advocate that Fixed Phage, based in Glasgow, is about a year and a half from seeing its products reach the aquaculture market. While phage science is far from new, the ability to administer phages in an aquatic environment has always proven difficult, due to the large volumes that require treatment, he explained. What Fixed Phage has done is develop a technology to immobilize and stabilize bacteriophages so that they can efficiently destroy harmful bacteria in finfish and crustaceans.

“All the time they are attacking bacteria,” Haas said of phages, which he added are harmless to plants, animals and humans. “They are not solely, but a large part, responsible for equilibrium on the planet. Without these things, we’d be in huge trouble. They’re nature’s way of keeping bacteria in check.”

Aquaculture industry observers may recall phages making news recently. In 2012, Dr. Donald Lightner at the University of Arizona – through a program initiated by the Responsible Aquaculture Foundation and the World Bank – identified the pathogen causing EMS, which caused billions of dollars in losses for shrimp farmers worldwide. Lightner’s research team determined that the acute hepatopancreatic necrosis disease (AHPND) pathogen was caused by a unique strain of the common bacterium Vibrio parahaemolyticus, that was infected by a phage, causing it to release a deadly toxin.

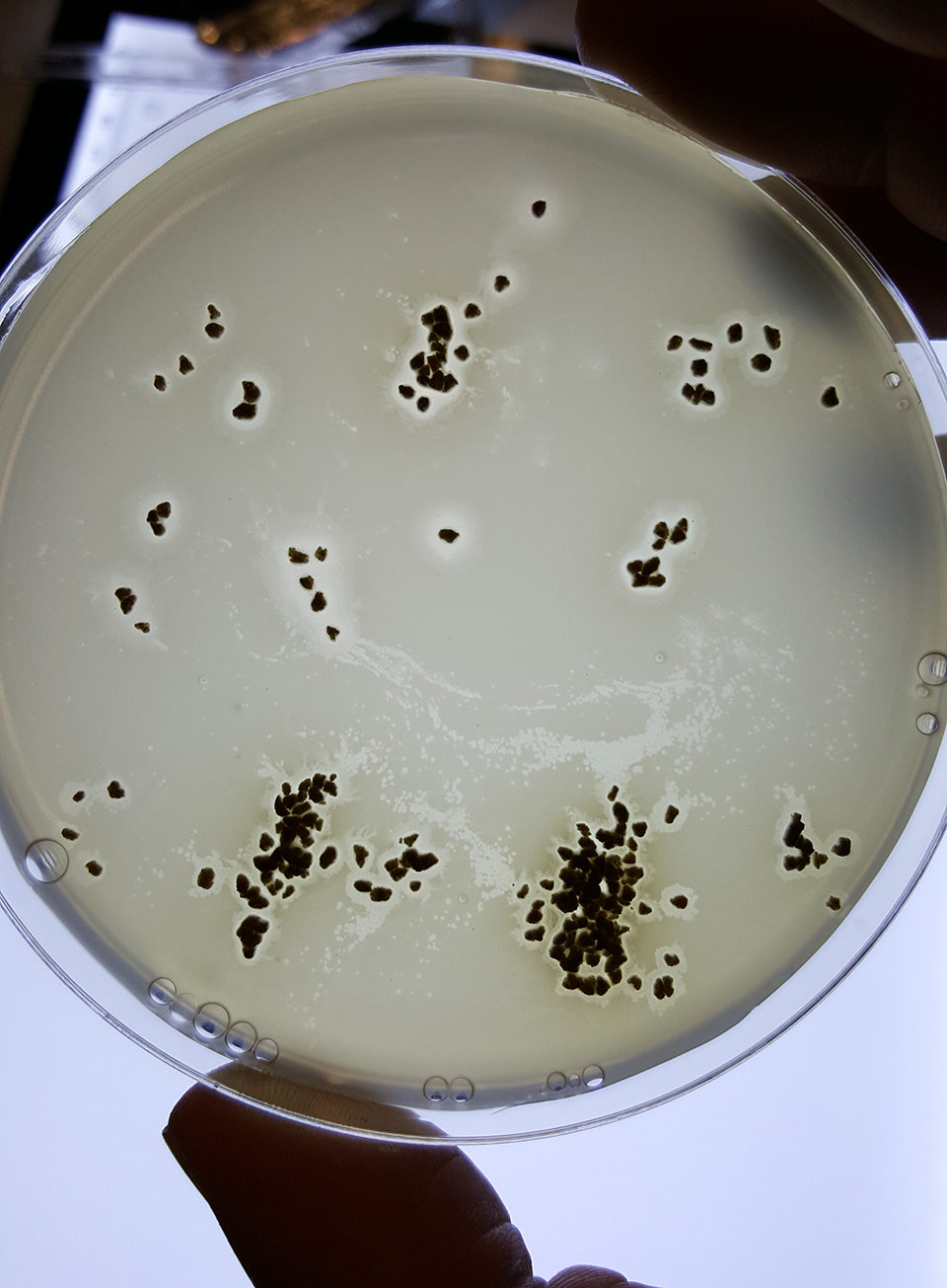

Phages are incredibly specific, said Haas. Fixed Phage has been able to isolate phages that will only specific strains of bacteria, leaving the rest of the microbiome intact. In other words, they’ve developed customized bacteria assassins.

“They will ignore everything else around them and go just where they want to go,” Haas said.

The potential uses of this technology go well beyond aquatic and land animal health purposes, he added. Fixed Phage technology is also applicable to agriculture products, such as root vegetables, and for food packaging generally. For instance, any food brought into a supermarket setting, like a chilled cabinet, is introduced to new bacteria throughout the production chain, some of which can cause spoilage. A phage treatment targeting these “problem bacteria” can extend shelf life.

Immobilized phage technology can also be deployed in hygiene products like creams, gels and liquids that target known domestic pathogens like salmonella and campylobacter.

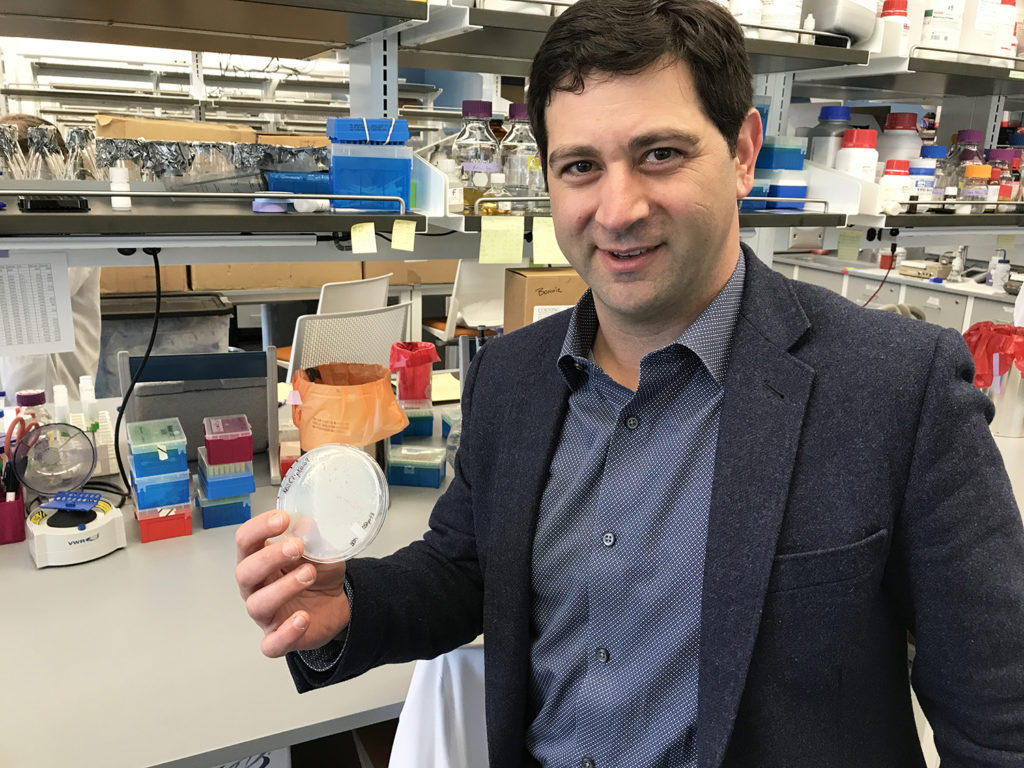

Aquaculture, however, shows a lot of promise, said the company’s senior scientist, Gordon Smith.

“From a technical perspective, aquaculture is one of the best fits for our technology and what it can do,” said Smith, who’s been with the company for five years. “As an enthusiastic fish hobbyist, I know the importance of having normal flora in the aquatic environment. Having an antimicrobial targeting the problem bacteria and leaving the others alone, I think is ideal for aquaculture, and can certainly augment some of the other technologies that are already in use by the industry.”

In their natural form, phages are liquid, making them difficult to work with. Moreover, they have a short shelf life. Bacteriophages are highly susceptible to environmental stress, particularly drying. Fixed Phage believes it has solved these constraints.

The company’s technology deploys the surface-modification method known as corona discharge to covalently bond, or immobilize, bacteriophages to a wide range of carrier materials – such as plastic sheets and powders – making them biologically active surfaces. And because they’re stable once attached, they can survive for 12 months with no cold storage needs.

“The breakthrough that our company made was the ability to ‘activate’ surfaces using a high-voltage plasma, which electrically charges the surface and allows the phages to irreversibly bond,” explained Haas. “The main advantage of the immobilization is that it gives substantially extended product stability. This means we have now a product that we can turn into commercially viable end results.”

Without these things, we’d be in huge trouble. They’re nature’s way of keeping bacteria in check.

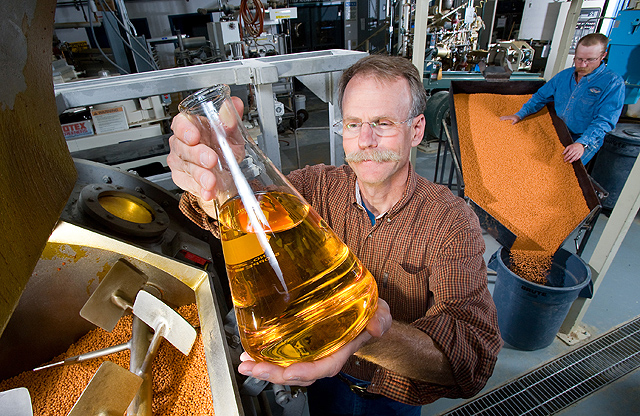

So while pouring a liquid phage into an aquaculture pond is less likely to achieve successful results, administering aquafeed pellets coated with the phage treatment can be an effective prophylactic or preventative treatment for fish and shrimp. And because bacterial issues can vary by geography, Fixed Phage said the treatments can be customized for such considerations.

“There are always new bacterial issues coming along. For us, we’ve got to balance with our partners which are the most commercially relevant,” said Haas. “At the end of the day, we’re trying to produce products where the increase in cost is minimized. There’s no point in producing something that’s so expensive that farmers won’t buy it. We’re tight at understanding our costs and areas. We expect to be able to produce new products that add less than 10 percent onto the cost of an existing product.”

Because Fixed Phage is bound by confidentiality agreements, Haas could not divulge any current commercial research-and-development partners. As Haas explained, Fixed Phage will not commercialize products, its partners will.

“Our team of world-class scientists bring the product development knowledge,” said Haas. “Our partners are the commercializing arms, and bring detailed knowledge of individual fields. Within 18 months we’ll have products on the market. We currently have parallel development programs under way to see rapid deployment of similar products for other bacterial issues in other target fields.”

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

James Wright

Editorial Manager

Global Aquaculture Alliance

Portsmouth, NH, USA

Tagged With

Related Posts

Innovation & Investment

Aquaculture Exchange: Ron Stotish, AquaBounty Technologies

Ron Stotish, CEO of AquaBounty Technologies, discusses being the first to produce a genetically modified (GM) farmed salmon deemed safe for consumption, the controversy surrounding his company's product and the potential of biotechnology.

Health & Welfare

Biosecurity practices on fish farms need beefing up

Biosecurity measures and preventive strategies are essential in any biological production chain. Properly planned and implemented biosecurity programs will enhance animal health, production and economics.

Aquafeeds

The pink powder that could revolutionize aquaculture

KnipBio, a Massachusetts-based biotechnology startup founded in 2013, is refining the manufacturing process for a promising aquaculture feed ingredient that may one day form the foundation of the food that farmed fish eat.

Aquafeeds

F3 takes on a new challenge – fish oil alternatives

Building off the success and excitement of the fish-free aquaculture feed cash-prize contest that concludes this fall, the F3 Challenge has set its sights on a new target: fish oil alternatives.