Plastic liners work but are expensive

Water seeps into and out of earthen ponds. Seepage into ponds can occur where their bottoms are excavated below the water table or where a pond within a complex of ponds is drained but adjacent ponds are full of water.

Ponds more commonly experience a net loss of water through seepage, which can be excessive if not addressed. Ponds constructed in sandy areas or other sites with permeable soils are most likely to have high seepage rates. However, unless proper construction techniques are used, ponds built in any kind of soil can seep too much.

Proactive measures

Compaction applied during construction is an important method for reducing seepage. Soils of embankments and bottoms should be compacted at about 95 percent of their optimum moisture content. Soils that are too moist should not be compacted, and water should be applied to excessively dry soil before compaction. A seepage cut-off core made with soil of high clay content can be installed in trenches and extended into dams or embankments to lessen seepage between the former land surface and the earthworks.

Where pond bottoms are expected to seep excessively, a 20- to 30-cm-thick “blanket” of soil with adequate clay content can be installed over the bottom and compacted. Drain pipes placed through embankments should have anti-seepage collars.

Seepage range

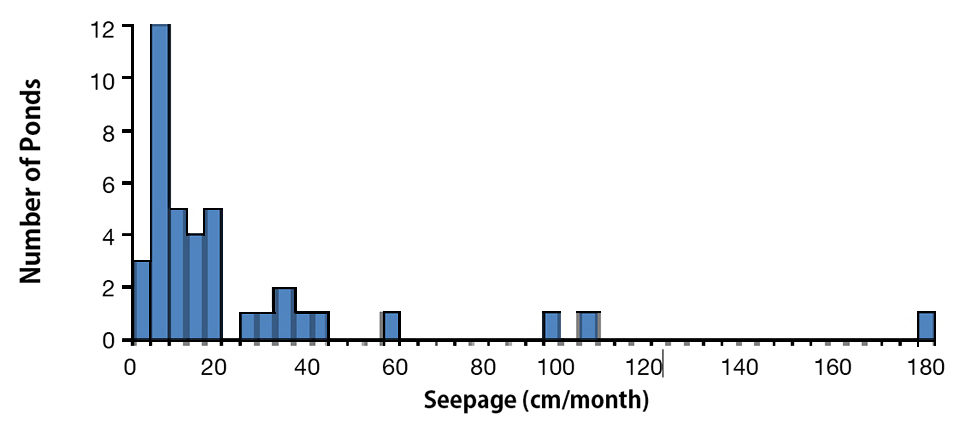

In a recent review of technical literature on pond seepage, the author determined estimated normal ranges of seepage for ponds. In the studies, data for a total of 39 watershed and embankment ponds used for sport fishing or livestock watering, and commercial and aquaculture research ponds in Honduras, Panama and several regions of the United States were examined. Soils at the pond sites varied in texture from clay to sandy. Seepage rates differed greatly with a range of 1.5-176.5 cm/month (Fig. 1).

However, the data skewed toward lower seepage rates.

The highest seepage rates were reported for ponds on sandy soil at a fisheries research station in Panama. The lowest rates were for ponds constructed in the Blackland Prairie region of Alabama, USA, on soils with a high concentration of expandable, smectite clay. The average seepage rate was 23.1 cm/month.

Table 1 classifies seepage categories for earthen ponds. Normal seepage was considered to be less than 20 cm/month.

Boyd, Seepage class categories, Table 1

| Class | Seepage Rate (cm/month) |

|---|

Class | Seepage Rate (cm/month) |

|---|---|

| Normal | < 20 |

| High | 20-40 |

| Excessive | > 40 |

Measuring seepage

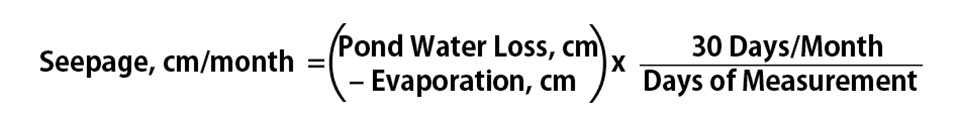

Pond managers who feel their ponds seep too much should measure and evaluate seepage rates against the normal ranges in Table 1. An estimate of seepage loss can be made fairly easily by measuring decline in water depth on a gauge or ruler mounted vertically in a pond over several days when there are no rainfall or other water additions.

Three to seven days will usually be required for the water level to decline enough for an accurate reading. The decline will represent both seepage and evaporation.

Class A pan evaporation multiplied by 0.8 is a good approximation of pond evaporation. An alternative is to install a small, floating plastic pan of water in the pond and measure the depth of water lost from the pan. It is important that no more than 2 or 3 cm of the sides of the pan extend above the water surface to minimize the effects on air movement that greatly affect evaporation rates. Water loss through evaporation varies greatly, but when air temperatures are 25-35 degrees-C, typical rates for ponds are 0.6-0.7 cm/day. Seepage can be estimated using the equation in Fig. 2.

Seepage rates tend to decline as ponds age and organic matter accumulates in their bottoms to seal off pore space in the soil.

Correcting seepage

The main avenue of seepage in some ponds is along drainpipes, around rocks left in embankments or dams, and through channels caused by roots of trees allowed to grow in dams. Visual inspection of the back sides of dams and embankments usually will verify the occurrence of this type of seepage as moist soil or standing water. Repairs for this type of seepage should focus on repairing drainpipes, removing rocks or trees, and filling seepage channels with clay soil and recompacting.

The simplest option for reducing seepage through pond bottoms and beneath embankments or dams is to drain the pond and recompact the bottom and sides of the embankment or dam, but this rarely is highly effective. Installation of a clay blanket over the bottom can stop seepage. The blanket should also be applied to the area in front of the dam or embankment to lessen the amount of water seeping beneath.

Sodium bentonite, a clay that swells to several times its volume when wet, can be mixed with bottom soil before recompacting. Chemical dispersing agents such as tetrasodium pyrophosphate, sodium tripolyphosphate, sodium chloride and sodium carbonate can also be mixed into the soil and the soil recompacted. For best results, an engineer with knowledge of the methodologies for sealing pond bottoms should be consulted.

Some pond owners have attempted to seal pond bottoms by spreading sodium bentonite over the pond water surface from a boat. This procedure is not effective, except possibly where a small area of the bottom is known to be responsible for the excessive seepage, and the bentonite treatment is concentrated in this area.

Plastic liners

Plastic liners can be placed over pond bottoms to completely stop seepage. Such membranes are durable and last for many years. Their main disadvantage is high cost. Expenses for the liner material and its installation can exceed $1 per square meter.

Water quality in plastic-lined ponds is often unstable because there is no soil to remove phosphorus. Phosphorus concentrations can increase as a result of feeding and cause dense phytoplankton blooms. These blooms tend to die after a few days, but the dead algae decompose with the release of phosphorus and cause the cycle to repeat itself. Also, the dead phytoplankton that accumulate on pond bottoms do not decompose as rapidly as in ponds with earthen bottoms.

Water quality problems in plastic-lined ponds can be lessened by installing a 15- to 20-cm layer of soil over all or part of the bottoms. This, however, greatly increases the cost of pond lining. The more common way of avoiding water quality problems is to install mechanical aeration. New heterotrophic “floc” systems for shrimp aquaculture require plastic-lined ponds and heavy mechanical aeration.

(Editor’s Note: This article was originally published in the March/April 2009 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Claude E. Boyd, Ph.D.

Department of Fisheries and Allied Aquacultures

Auburn University

Alabama 36849 USA

Tagged With

Related Posts

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Responsibility

Appraising pond liners for shrimp culture

The use of plastic-lined ponds by shrimp farmers can significantly improve production efficiency, support more production cycles per year, and higher mechanical aeration rates and stocking densities. The capital cost of lining ponds can be very significant, so a thorough feasibility analysis is recommended when considering this production tool.

Health & Welfare

Commercial demonstration of in-pond raceways

Results of a demonstration project of the In-Pond Raceway System (IPRS) technology in seven tilapia raceways at a commercial farm in Mexico showed the potential for increasing fish production with this environmentally sustainable culture system.

Responsibility

Drying, liming, other treatments disinfect pond bottoms

The traditional way of destroying organisms in pond bottoms is thorough dry-out for a week or longer. Fish toxicants and liming can kill unwanted parasites.