Despite the unprecedented disruption caused by COVID-19, the UK’s two commercial shrimp farming ventures continue to capitalize on the market’s growing demand for trustworthy, locally produced food

Brits love shrimp. Actually, that’s not entirely accurate. In the United Kingdom, the word “shrimp” tends to refer to the small brown species Crangon crangon, which is common to the country’s coasts. As delicious as these are, the shrimp most coveted by U.K. consumers are better known in the market as “prawns,” mainly comprising the sweet, coldwater Pandalus borealis, caught in the Barents Sea and fisheries around Iceland, Greenland and northern Canada, and also the larger, widely farmed warmwater white-legged and black tiger varieties, Penaeus vannamei and Penaeus monodon, respectively.

Collectively, U.K. retail sales of these crustaceans top 40,000 metric tons (MT), some 180 million units, generating more than £500 million ($637 million, €561 million). A similarly large volume is sold through the country’s foodservice channels.

The coldwater prawn has long been a market staple, while the tropical varieties – both identified as “king prawns” – are much more recent arrivals. And yet the latter’s far greater availability and considerable versatility has made them a firm favorite throughout the country. It’s perhaps not that surprising, therefore, that the market’s affection for the king prawn has inspired the creation of not one but two companies: FloGro Fresh in Lincolnshire, England; and Great British Prawns (GBP) in Stirlingshire, Scotland.

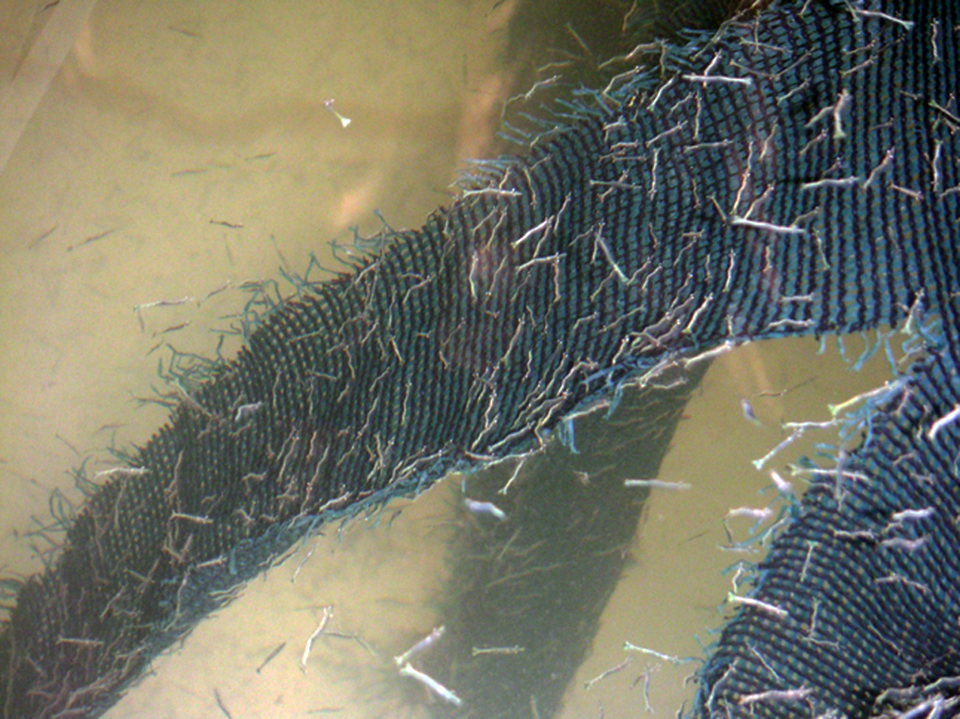

Although both of these ventures are farming vannamei in indoor recirculating aquaculture systems (RAS) and were also both focused on supplying to local restaurant markets up until the arrival of the COVID-19 pandemic, there are some clear differences in their farming and business models. With regards to the actual production, for example, FloGro grows out its prawns in a biofloc system while GBP follows a clearwater filtration approach.

Crucially, both companies insist that there’s a strong and growing U.K. market for products that can be produced locally and supplied fresh to consumers, and that this will be the foundation for their long-term growth.

Navigating adversity

FloGro undertook its first production trials in 2013. Full-scale commercial grow-outs commenced in 2015, with an “overwhelmingly positive” customer response to the quality of the product, managing director, Ralph Maxwell, told The Advocate.

Chefs were receiving their orders – freshly harvested – within 24 hours of placing them, while the Marine Conservation Society (MCS) gave its approval for the production method and the sustainability of the prawns. Indeed, everything was progressing nicely for the venture right up until the lockdown.

Seeing that lot of fishing and fish farming businesses would struggle to deal with the Coronavirus storm, it was clear to Maxwell that new strategies were required. And fast.

“All of our restaurant and wholesale customers closed, and with those markets disappearing overnight, we had to build a transactional retail website in a matter of days, which we duly did,” Maxwell said. “I feel for a lot of our old customers. However, we needed to move forward and adapt to the situation.”

As seen in most affected markets, U.K. retail – conventional and particularly online – has benefitted from the temporary closure of foodservice channels and the lockdown measures. Moreover, with international supply chains continuing to be hugely disrupted by the health crisis, locally produced foods have become much more important to consumers. Indeed, thanks to its shift towards retail, FloGro’s production has remained much the same.

“All of our customers are passionate about prawns. They all want to buy from us, and we’ve been very busy selling online. Our plan is to gradually build on this platform, because I feel that some of the changes we’re seeing in the market will be permanent. There are also other online retailers and other online food companies and we are supplying them as best we can,” Maxwell said. “We want to develop the business, but we must be careful and cautious too. In the current climate, the focus must be on keeping our head above water and making sure that we are ready to capitalize on what comes next.”

Self-investment

It’s a similar success story for GBP, with CEO Dougie Allen confirming that the large drop in restaurant sales has been offset by a surge in retail commerce.

At the same time, the current landscape has provided his company with an ideal juncture to take stock of its progress so far and to plan for its future, he said.

“COVID has thrown us an unexpected opportunity. We pivoted quickly to the market’s changing demands, and we’ve used the time to invest in our recent achievements,” Allen said. “It’s a fleeting opportunity that we have taken with both hands, and I firmly believe that it will serve us well.”

Allen explained that the idea to establish an aquaculture tech company came about more than five years ago, while the re-branding to Great British Prawns took place in 2018.

While lots of important lessons have been learned along the way, the focus throughout has always been on demonstrating that its technology offers a “badly needed, viable and sustainable” food production solution, he said.

“We have sought to address lots of related issues throughout the production process, not least carbon footprint, food miles, traceability, etc. GBP is about doing the right thing now to address the consumer demand for clean energy and for a farming system that removes the need for antibiotics and chemical additives while ensuring the best prawn husbandry. We have the means within this country to produce a home-grown and fully-traceable fresh product, fed on increasingly sustainable feeds, that can then be with the chef or consumer within a matter of hours,” Allen said. “We have been nimble enough to see and take onboard what’s going on outside and beyond. We have a large and amazing support network today who care about what is happening to the planet. In our own way, GBP is leading the transition to more responsible aquaculture while taking forward the best traditions of all farming.”

Mindful markets

Inadvertently, the coronavirus crisis has added further weight to both farms’ principle that local production must be encouraged as it’s an essential part of a sustainable food landscape.

Certainly, in the interim, while complex international supply chains remain heavily disrupted, many of those domestic operations that have been able to remain open for business have taken greater market share. Further fueling this trend is the rising tide of consumer engagement in food production systems and supply chain issues, not least in the seafood sector. As such, values like provenance, food safety, best-practice and traceability are increasingly driving tangible increases in the demand for local, low-volume production as opposed to mass produced and mass transit foods.

“There’s certainly a groundswell of feeling that we can do more in our own country and develop our own food. That’s already brought us lots of customer support, and I hope that it’s also encouraging lots of other British food companies too,” Maxwell said.

Editor’s note: This article has been amended since its original publish date to reflect accurate U.K. shrimp retail sales figures, which equal about 40,000 metric tons and not the 180,000 previously reported. This total is about 180 million units, according to Seafish. We regret the error.

Follow the Advocate on Twitter @GAA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Jason Holland

Jason Holland is a London-based writer for the international seafood, aquaculture and fisheries sectors. Jason has accrued more than 25 years’ experience as a B2B journalist, editor and communications consultant – a career that has taken him all over the world. He believes he found his true professional calling in 2004 when he started documenting the many facets of the international seafood industry, and particularly those enterprises and individuals bringing change to it.

Related Posts

Intelligence

A land grab for salmon (and shrimp) in upstate New York

The operators of Hudson Valley Fish Farm see their inland locale as a pilot to prove that land-based fish farming, located in close proximity to major metropolitan markets, can be successful.

Responsibility

Biofloc reduces feed, filtration costs in recirculating shrimp nursery system

Trials with recirculating shrimp nursery systems in India supported the use of biofloc. To control ammonia is a way to reduce filtration costs.

Innovation & Investment

Canadian father-son team merge talents to improve RAS

JLH Consulting has spent the last four years working on a better RAS setup designed to prevent overcrowding of fish and ultra-low energy demand.

Innovation & Investment

Plastic 2.Ocean: Seafood packaging, made from shellfish

A new type of chitosan-based bioplastic, made from shellfish shells, emerges as a potential solution for global food waste and marine plastic pollution.