Ingredient selection

The production of high-quality aquatic feeds depends on three interrelated steps: the accurate definition of nutrition requirements of the target animal, selection of quality ingredients, and use of appropriate manufacturing methods. The interrelated nature of these steps is especially evident in the case of ingredient selection.

Quality ingredients are those that meet digestible nutrient requirements, do not exceed limits of antinutritional factors, and provide adequate physical integrity of the pellet. From a nutritional standpoint, the major ingredients can be classified as sources of protein or energy.

Protein sources

Ingredients that are sources of protein can be of animal or plant origin. Those from animal origin can be further divided into marine animal proteins (fish meal, squid meal, etc.) or land animal proteins (meat and bone meal, blood meal, etc.).

The animal protein most commonly used in aquatic feeds is fishmeal. The quality of fishmeal principally depends on the freshness of the raw material and processing temperature.

Proteins processed at high temperatures for extended periods of time are less digestible. This is because their molecular structure is changed, making their component amino acids less digestible. Therefore, it is important to understand the process used to produce the proteins used in your feed formula, as well as the quality of raw materials from which they were made. Processing of ingredients can also affect pellet integrity.

The most commonly used plant protein in aquatic feeds is soybean meal, which is a high-protein source readily available worldwide. However, this oilseed meal cannot completely replace marine or land animal proteins due to its imbalanced amino acid profile.

As most plant proteins, soybean meal is deficient in the sulfur-containing amino acids (methionine and cysteine). Therefore, the inclusion at high levels of this protein source will depend on the inclusion of methionine and cysteine from synthetic amino acids or other protein sources.

The combination of proteins with different amino acid profiles can lead to a protein of higher nutritional value. This is known as protein complementation, where the deficiencies of the amino acids in one protein are complemented by those of another. For example, soybean meal is relatively rich in lysine, but deficient in methionine. However, its amino acid profile can be balanced by combining it with corn gluten meal, which is deficient in lysine, but rich in methionine.

Energy sources

Although proteins can serve as a source of energy in aquatic feeds, nutritionists strive to spare the use of protein by providing less-expensive sources of energy in the forms of fats and carbohydrates. Fats include animal fat, fish oil, and vegetable oil, which also serves as a source of essential fatty acids. Typical carbohydrate sources include grains such as wheat, corn, and rice, which also contribute a significant amount of protein.

Pellet quality

Certain nutritive ingredients have distinct binding properties that improve pellet hardness, durability, and water stability. The major types of nutritive binders are starches and native proteins.

Starches are the major carbohydrates within grains such as corn, wheat and rice. Proper hydration and cooking procedures (gelatinization) release long, branched molecules of amylose and amylopectin from starch granules. This increases energy digestibility and pellet quality. Depending on the starch level and manufacturing process, feed millers can make pellets that float (extrusion) or sink (pelleting process.)

Proteins are considered “native” in their raw, intact condition. As native proteins are cooked or dried, their soluble, elastic structure irreversibly crystallizes in a process called denaturization.

This is the gelling process that occurs when a raw egg is cooked. It can be an important binding propoerty for feeds. However, most high-protein animal and plant meals, such as fishmeal, meat and bone meal, feather meal, and soybean meal, are denatured during processing. Native proteins retain their binding functionality through special processing.

Native protein ingredients include wheat gluten, isolated soy protein, gelatin, fish surimi, and spray-dried plasma. Wheat gluten is commonly used as a nutritive binder in shrimp feeds.

Ingredient interactions

The most important ingredient interaction is between protein and starch. For example, wheat flour protein and its starchy carbohydrate portion interact to form a matrix. When swollen and gelatinized, the starch acts as an anchor point to facilitate the formation of the gluten fibrils.

In the case of aquatic feeds, this interaction is important in the production of water-stable feeds because the resulting matrix helps to form a tight structure that is impermeable to water. This tight structure also serves as a net to hold other ingredients such as trace elements with reduced leaching to the aqueous environment.

A number of elements affect the protein-starch interaction. Increasing protein content in a formula can have a positive effect by strengthening the protein-starch interactions. Increasing the level of gluten or other proteins (but not denatured animal proteins), or use of high-gluten wheat in a formulation, improves water stability. The addition of non-gluten protein, such as soybean meal, has the opposite effect.

High inclusions of oil decrease the bond between starch and protein fractions, but improve the bond between lipids and starch molecules. Therefore, it is very important that the largest amounts of oil be added at the end of the production process, possibly after cooling or drying.

Fiber can also have an effect on protein-starch interactions. A complex chain of carbohydrates, fiber is only digestible to certain micro flora (fungi, and bacteria in the rumen or caecum) and can interfere with the bonding between starch molecules and proteins, or proteins and other proteins.

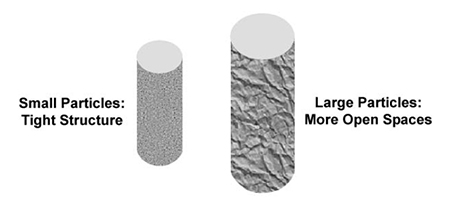

Fibrous ingredients, depending on particle size, can also have a negative effect on water stability. Large fiber particles not only interfere with protein-to-protein or starch-to-protein cross-linking, but also act as avenues for water penetration into the feed. As wet fibers expand, they can break the integrity of the feed, causing more water to enter.

Feed uniformity

A uniform feed is one that is consistent in nutritional value and physical characteristics, including pellet durability, density, and water stability. Feed uniformity starts with quality raw materials. Therefore, ingredients must be purchased based on such standards as digestible nutrient composition, protein solubility, gluten content, starch content) and physical characteristics (particle size and shape, density, etc.). To produce feeds of uniform quality, it is also important to have uniform and consistent manufacturing practices.

Conclusion

Selection of appropriate ingredients is crucial for production of a high-quality aquatic feed. Excessive drying temperature can diminish the digestibility of protein ingredients. Amino acid deficiencies can be avoided through blending of complementary proteins. Fats and carbohydrates are the principal energy sources. Pellet integrity can be achieved through the use of nutritive binders such as starch and native protein.

(Editor’s Note: This article was originally published in the April 2001 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

Tagged With

Related Posts

Aquafeeds

Aquatic feed manufacturing, part 2

The first processing step in the production of shrimp feeds is the grinding of ingredients for a formula, either individually or as a group.

Aquafeeds

Aquatic feed manufacturing, part 3

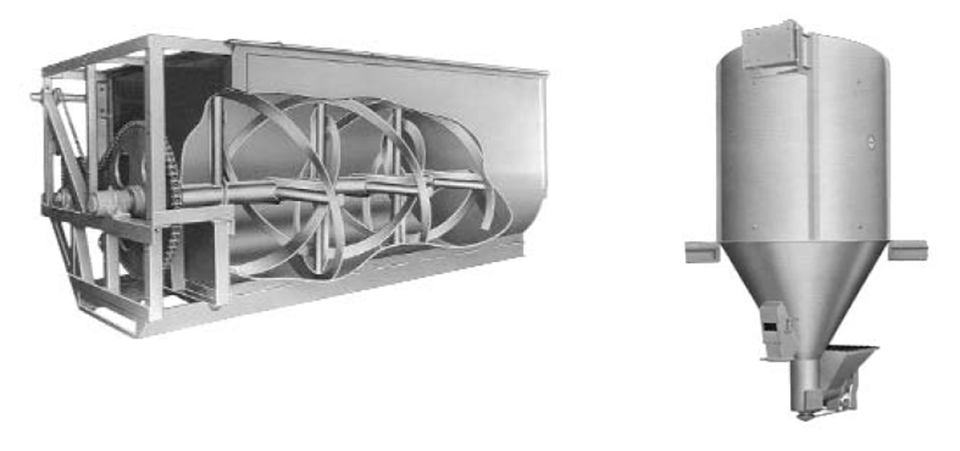

The mixing process is the heart of aquatic feed manufacturing. All the ingredients of a formula designed for the target animal are put together.

Aquafeeds

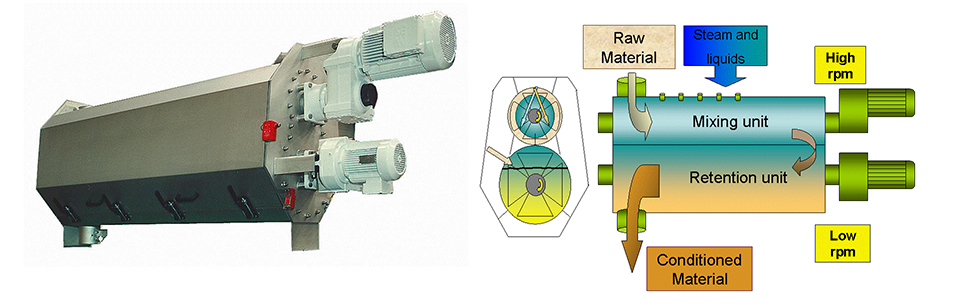

A closer look at preconditioning: Mixing, residence time

During the aquafeed manufacturing process, preconditioning increases the moisture content and temperature of feed meal particles.

Aquafeeds

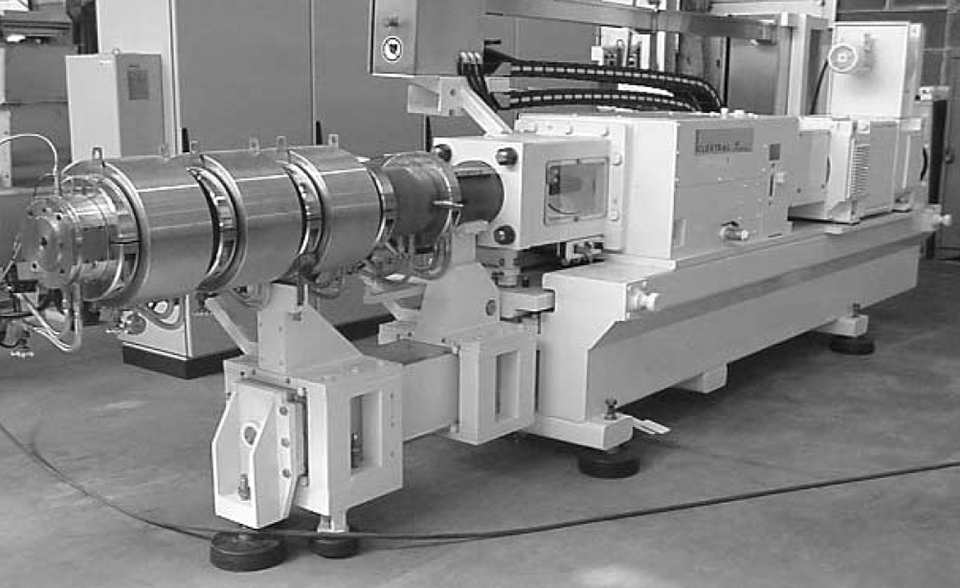

Extrusion processing of aquatic feeds, Part 1

Depending on the extrusion processing conditions and ingredients used, different products such as floating or sinking feed can be produced.