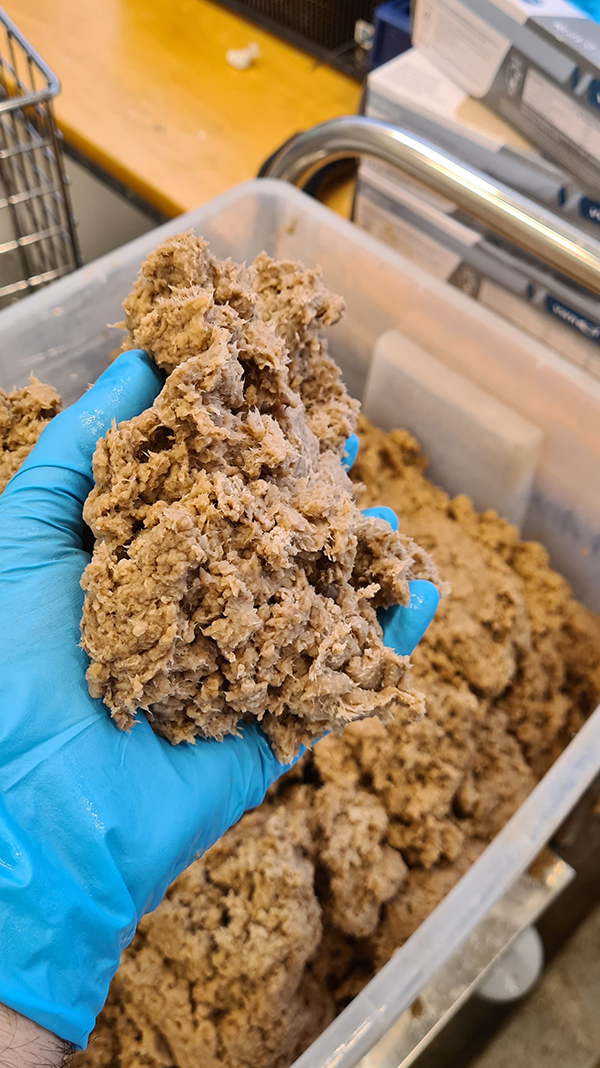

Seaqure labs’ mycoprotein powder made from fungi and agricultural waste products has a wide variety of applications for both animals and humans

Creating a protein-rich, sustainable fish feed is an ongoing challenge for aquaculture. While current feeds are suitable, the source of the ingredients will need to expand and diversify so that aquaculture can help meet what is a still growing worldwide demand for protein, much of which is and will be derived from fish.

Seaqure labs, a Sweden-based company founded earlier this year, has found a potential new way to get that protein: fungus. For its discovery, Seaqure labs has been named a finalist in the Global Seafood Alliance’s Responsible Seafood Innovation Awards, in the aquaculture category. Three finalists from the fisheries and aquaculture categories will present at the Responsible Seafood Summit on Oct. 22 in St Andrews, Scotland. Attendees will determine the winner by poll.

“We’re aiming to produce the protein ingredient in fish pellets, which is one of the more expensive parts with the highest climate footprint,” Albin Frick, co-founder and COO of Seaqure labs, told the Advocate.

The fungi, which is already being used in the tempeh industry, are fed byproducts like agricultural waste. They’re put together in a bioreactor and, much like yeast is fermented to produce the glucose and carbon dioxide to make beer, the fungi create a mycoprotein powder with a protein content of more than 60 percent.

Seaqure’s process is sustainable in multiple ways, said Frick. First, it doesn’t require the creation of soybean or fish-based fishmeal. Since the fungi are “feeding” on an already existing byproduct, they’re recycling materials that may otherwise go into landfills, contributing to greenhouse gas emissions.

This reuse of byproducts also reduces the dependency on wild-capture fish for aquaculture’s growth. “Fishing up all the fish in the sea to make fish bone meal has a high protein content to feed other fish [but] it’s not sustainable,” said Frick.

Seaqure’s process is also not weather-dependent and can be launched just about anywhere. This cuts down on transportation costs and related carbon dioxide emissions, in addition to the general ease of making fish food sources wherever it’s needed.

According to Seaqure’s own research, its mycoprotein outperforms soybean meal in a few ways: It has a superior amino acid profile, which is beneficial for fish health and promotes faster growth rates. They also found that the feed “has prebiotic properties that help reduce the need for antibiotics, and we’ve seen a higher survival rate among both the younger and older fishes that consume it,” he said.

Frick said their feed has the potential for a smaller inclusion rate, meaning that a lower percentage of their mycoprotein needs to be included in the feed to achieve optimal nutritional benefits.

“We are currently targeting an inclusion rate of 5 to 15 percent of the total feed pellet,” he said. “This smaller amount is highly efficient, which allows us to produce a larger quantity of feed pellets from the same volume of protein, thus increasing the overall output.”

For its work, Seaqure lab was also recently named one of the top 10 most promising aquaculture ideas at the North Atlantic Seafood Forum in Norway in 2023. Seaqure is also part of the EIT food seedbed incubator, which selected 50 novel innovations from across Europe to validate the commercial potential for promising tech-based ventures.

Right now, Seaqure has a small production line in Gothenberg, Sweden, where it established a laboratory. It has signed letters of intent with some fish farms and is planning to collaborate with a byproduct supplier to produce larger quantities of feedstock. The company is also exploring different kinds of feedstocks, including potential resources in Scotland and Ireland.

“The peel of a potato is very good input material for us, and a potential way of closing the loop. We could use old potatoes thrown away to use in high-content protein for fish feed in Scotland and Ireland,” he said.

Frick said they focused on fish feed because he sees the need for making a more sustainable product in this field, but also because co-founder and CTO Sajjad Karimi has a double Ph.D. in fish nutrition and resource recovery. This is what they know, said Frick, who has a background in entrepreneurship and business design.

But the two don’t plan to stop here either. Since their fungi is also already commonly used in tempeh, “it’s good to know there will be no effects in humans because it’s been so well documented,” he said. He sees a potential for their process to create protein beyond the aquaculture industry. The protein “can be used for protein for a puppy or a kitten or pigs or even humans. There’s a big variety of different applications, but we’re trying to think of it for fish.”

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Jen A. Miller

Jen A. Miller is a New Jersey-based writer whose work has appeared in everything from The New York Times to Engineering News Record.

Tagged With

Related Posts

Intelligence

Will 2024 be the year of the tinned fish?

Tinned fish is a growing food trend in the U.S. market, and more companies are creating products using locally sourced seafood.

Fisheries

Can dam removal actually restore fish populations in U.S. rivers?

Dams have helped build nations but fish – and river health – have paid a steep price. Dam removal can have restorative effects on ecosystems.

Fisheries

‘A world down below’ – Deeper fishing insights lead to better tools for bycatch reduction

High-tech bycatch reduction devices – data analytics, cameras and sensors – are in play but SafetyNet Technologies says the secret is collaboration.

Aquafeeds

Insect farming is gaining ground as aquaculture awaits its emergence

Black soldier fly larvae producers are hoping to go “mainstream” and gain wider acceptance in aquaculture amid concerns about high costs.