Quantitative method standardizes testing equipment, procedures

One of the most important and discussed quality parameters of aquafeeds is their water stability, or hydrostability. The feed must be sufficiently stable after immersion in water to prevent rapid deterioration, critical nutrient loss and wastage. Aquafeeds can lose nutrients rapidly after immersion, so it is important that feeds have adequate stability and attractability after immersion in water to maximize nutrient uptake by cultured animals and to minimize wastage.

In the case of shrimp feeds, hydrostability is even more important, because the feed pellets must maintain their physical integrity long enough for the animals to detect and consume them, and this can be a very short window of one to two hours depending on attractants, binders and ingredients used in the formulation, and other factors. Inadequate hydrostability results in unconsumed, wasted feed and increased organic loading of ponds and effluents, higher feed conversions and reduced overall efficiency and profitability.

Regardless of the method used, hydrostability measurements must provide a quantitative and replicable procedure that eliminates the subjective assessment of quality. Measurable attributes can be used as quality controls to assure that manufactured feeds perform as expected at farms.

Assessing water stability of pellets

At many shrimp farms, water stability is often assessed in many different, subjective ways. One is by simply putting some pellets in a glass with water and observing how quickly they disintegrate or how much leaching occurs. Another method is to tie a pellet at the end of a string and submerge it in water until the pellet breaks into pieces or disintegrates.

Others use their expertise in chop stick handling to pick up moist pellets to evaluate and determine how pellets maintain their integrity. But none of these is a quantitative method to determine water stability, as they do not provide a repeatable and quantitative technique that can be shared by feed manufacturers and the farmers or biologists in charge of assessing feed quality at farms.

The ways to determine water stability used by researchers are more expensive and require special equipment, but yield more accurate quantitative data. The following method is particularly recommended for shrimp feeds.

Equipment needed and feed sample collection

The following equipment is needed to carry out this hydrostability assessment of aquafeeds: orbital agitator; oven capable of drying product to 130 degrees-C; graduated cylinder (100 mL); Erlenmeyer flasks (250 mL); screen Tyler No. 20; infrared moisture meter or similar; and weighing scale.

A composite sample is collected, with 10-gram samples collected from every three to four bags until 20 samples have been collected for a particular run of feed or feed shipment. Each sample will be placed in a common bag, and after the 20 samples are collected, the pellets will be mixed by hand to have a composite sample for water stability analysis. After the composite sample has been mixed, two 25 g (replicates) subsamples of pellets are weighed and subjected to the laboratory procedure that follows.

Laboratory test procedures

Weigh 25 g of pre-screened (fines removed) pellets, and place them in an Erlenmeyer flask. Add 100 mL of fresh water (25 degrees-C) to the Erlenmeyer flask(s) containing the pellets.

Then place the Erlenmeyer flask in the orbital agitator, ensuring the clamps hold the flasks snuggly, and start and run the orbital agitator at 200 rpm for a total time of 30 minutes. Once the agitator stops, place the pellets on the No. 20 mesh screen and wash off fines with tap water. This step will remove any fine pieces that disintegrated during the agitation and are smaller than the screen size.

After gently washing the pellets on the screens allow excess water to drip off (approximately 5 minutes), then place all screens in the convection oven for two hours at 130 degrees-C. After drying is completed, remove the screens with pellets from the oven and allow them to cool to ambient temperature, and after pellets are cooled, record the weight of each sample.

Calculations of water stability

For the calculation, use the following formula:

Water stability (%) = dried pellet weight (g) / initial pellet weight (g)

Multiply the result by 100 to convert to a percentage. The percentage number then needs to be corrected for the moisture content of the initial sample. Therefore, it is necessary to know the moisture content of both the initial pellet sample and that of the dried pellet sample.

For example, if the initial moisture content of a product is 11 percent, and the moisture content of the final sample is 2 percent after drying, adjust both weights to an equal basis. The moisture is 11 minus 2 or 9 percent. Therefore, add 9 percent back to the dried product or multiply the final result by 1.09.

The sample weight = 25 g; the final sample weight = 18.5 g; the moisture of initial sample = 11 percent; the moisture of final sample = 2 percent; then, water stability is initially = (18.5/25) x 100 = 74 percent, and with the correction for moisture = 74 percent x 1.09 = 80.66 percent is the final value for hydrostability.

Interpreting test results

After values are obtained, how does a final value of 70 or 80 percent correlate with water stability? Higher percentages indicate higher feed water stability, since the values obtained indicate how the pellets hold their physical integrity after being subjected to the test treatment. The amount of dry matter loss will vary depending on the formula. Feeds lower in protein – and higher in starch – have higher water stability values than feeds with high levels of protein and fat.

As a guide when using the method described here, feeds with 35 percent crude protein and at least 30 percent starch should have a water stability of 80 percent or higher after one day of manufacture. Feeds with 40 percent crude protein and 6 to 8 percent fat should have a water stability of 75 percent or higher, and feeds with 45 percent crude protein and 8 to 10 percent fat should have 70 percent water stability.

The hydrostability of shrimp aquafeed formulas can be improved by increasing the levels of natural or artificial binders, or optimizing processing conditions by preconditioning mash moisture and temperature, and adjusting postconditioning residence time and temperature, pellet die working area, and meal particle size.

Perspectives

The physical stability and the nutrient leaching of shrimp feeds are an important component of feed quality control. The physical stability of feed pellets after immersion in pond water is an environmental and financial issue, and important in the manufacture of aquafeeds, especially for shrimp, and must be properly assessed.

Regardless of the method used to determine hydrostability of shrimp aquafeeds, the method must provide quantitative procedure that can be easily replicable and that eliminates the subjective assessment of quality. Measurable attributes can be used as quality control and as assurance that the feeds made will perform as expected once used in the farm.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

Tagged With

Related Posts

Aquafeeds

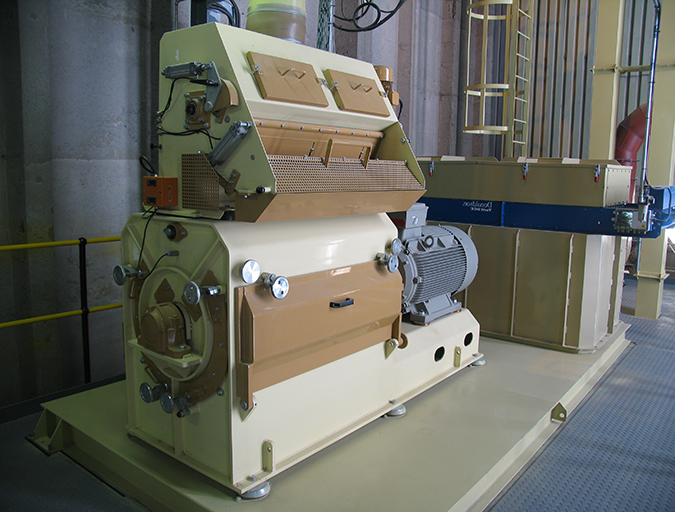

Twin screw technology for better extruded feeds

Extrusion processing can be a better alternative to produce high quality-low- polluting shrimp feeds. Extruded pellets with high water stability can be produced by controlling the Specific Mechanical Energy (SME) and without the inclusion of artificial binders. New extruders are equipped with state-of-the art SME controls that permit the adjustment of the SME to the desired range, to produce soft very hydrostable pellets.

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Aquafeeds

Shrimp feeds depend on proper ingredient grinding

The proper feed particle sizes of aquafeed ingredients are established by the nutritional requirements of the species targeted and by the feed manufacturing process used. For proper ingredient particle sizes, various characteristics are very important, including particle size distribution and pellet density.

Aquafeeds

Optimizing crucial cost centers for shrimp feed manufacturing

Assuring that aquafeed ingredients are processed properly into a high-quality product requires monitoring each manufacturing process through the proper in-line quality assurance, to produce a consistent quality continuously.