Performance, immunity and flesh quality

Currently, almost 6 million metric tons (MT) of tilapia are grown annually worldwide. In a quick calculation, considering an average production cost of U.S. $0.80 per kg, and that, on average, feed represents 60 percent of such cost (i.e. 48 cents per kg), it is estimated that tilapia producers globally spend at least $2.88 billion in nutrition every year.

By the end of the 1980s, tilapia were produced predominantly in ponds, in a culture system that combined natural foods and supplemental feed. There were few reports of nutritional deficiencies and diseases. The intensification of aquaculture over the last three decades multiplied the number of tilapia farms. This has increased the flow of fish among production and consumption sites (from fry to harvest size fish). Superior genetic materials have been transferred among countries, and the fish stocking densities in a particular area have increased over the years.

All of these developments contributed to increase disease outbreaks. Bacterial strains and other increasingly specialized and aggressive pathogens have been causing high sanitary and economic concerns to tilapia producers worldwide. Such challenges require fish nutritionists to reevaluate nutrient requirements (amino acids, minerals, vitamins, fatty acids, and other nutrients) not only to maximize growth performance, but also to strength the immunity of tilapia.

In addition, many other substances (classified as prebiotic, herbal extracts, organic acids and probiotics), although not yet considered as essential nutrients, have already been proved to enhance overall condition and health of many aquatic species, including tilapia. That is the current status for nutritional research with tilapia and many other cultured fishes. The focus is on immuno- and high-performance nutrition, where scientists are not only investigating performance, but also the impact of nutrients and additives on the tolerance of fish to specific pathogens. Nutrigenomic tools are also helping researchers to better understand the expression of genes that regulate growth and health of fish.

This article – adapted from the original publication at Panorama da Aquicultura – Brazil (Vol. 169, 2018, pages 42-49) – discusses various specific nutrition and physiology aspects of importance to nutritional and feed management, emphasizing the role of nutrition on the immunity, health and quality of tilapia products.

Poikilothermia, thermal comfort and protein/energy ratio

Fish are poikilothermic, that is, they do not regulate their internal body temperature. Thus, fish do not spend food energy to heat their bodies. This makes fish, when within their thermal comfort range, more efficient in the use of feed and producing feed conversion ratios (FCR; feed/weight gain) of 1.1 to 1.6, compared to 1.8 to 2.2 for chicken and 2.7 to 3.0 for swine.

Because fishes cannot heat their bodies, they do not need too much energy in the feed. The best growth performance of fish is achieved with feeds with a ration with digestible energy/crude protein (DE/CP) ratio of around 8 to 11 kcal DE per gram of protein. To achieve this DE/CP ratio, commercial feeds must have 28 to 45 percent CP. Comparing such high protein feeds with feeds used for chicken or pigs (with 14 to 22 percent CP), most people tend to erroneously believe that fish are much more demanding on protein than poultry or swine. But this is not true. If a chicken consumes 2 kg of a feed with 20 percent protein to gain a kilo of weight, it is ingesting 400 grams of CP/kg of weight gained. A pig fed on a 16 percent CP feed with an FCR of 2.8 is ingesting 448 grams of CP/kg of weight gained. Tilapia fed on 32 percent CP feed with an FCR of 1.3 is ingesting 416 grams of CP/kg of weight gain. Thus, all these species are very close when protein consumption per kilo of gain is considered (Table 1).

Kubitza, Tilapia nutrition, Table 1

| CP in feed (g/100 g of feed) | FCR | Protein consumed per kilo of weight gain | |

|---|---|---|---|

| Chicken | 200 | 2.0 | 400 g |

| Pigs | 160 | 2.8 | 448 g |

| Fish | 320 | 1.3 | 416 g |

Tropical fishes like tilapia have thermal comfort ranges between 27 and 30 degrees-C. Within this thermal range, their feed consumption, digestion, overall metabolism, weight gain, feed efficiency and immunity are maximized.

Crude fiber in tilapia feeds

The crude fiber fraction of the feed (cellulose, hemicellulose, lignin and others) is not digested, so we consider it contributes virtually zero energy to the fish. But the increase in dietary fiber speeds up the passage of feed through the digestive tract of fish. Consequently, the exposure time of feed to digestion and absorption can be greatly reduced, impairing feed utilization (as measured by feed efficiency or feed conversion ratio (FCR). Meurer et al (2003) did not observe reduced performance of 1- to 7-gram tilapia fingerlings fed diets containing up to 8.5 percent of crude fiber. Ali and Al-Asgah (2001) observed that juvenile tilapia of 10 to 40 grams had the worst growth, feed conversion and protein utilization when feeds with 11 and 14 percent fiber were used, compared to fish that received feeds with 8 percent or less fiber. Shiau et al (1988) observed growth reduction and poor FCR in tilapia eating feeds containing 6, 10 and 14 percent fiber, compared to fish fed on feeds with only 2 percent fiber.

Osmoregulation and electrolytes in the feed

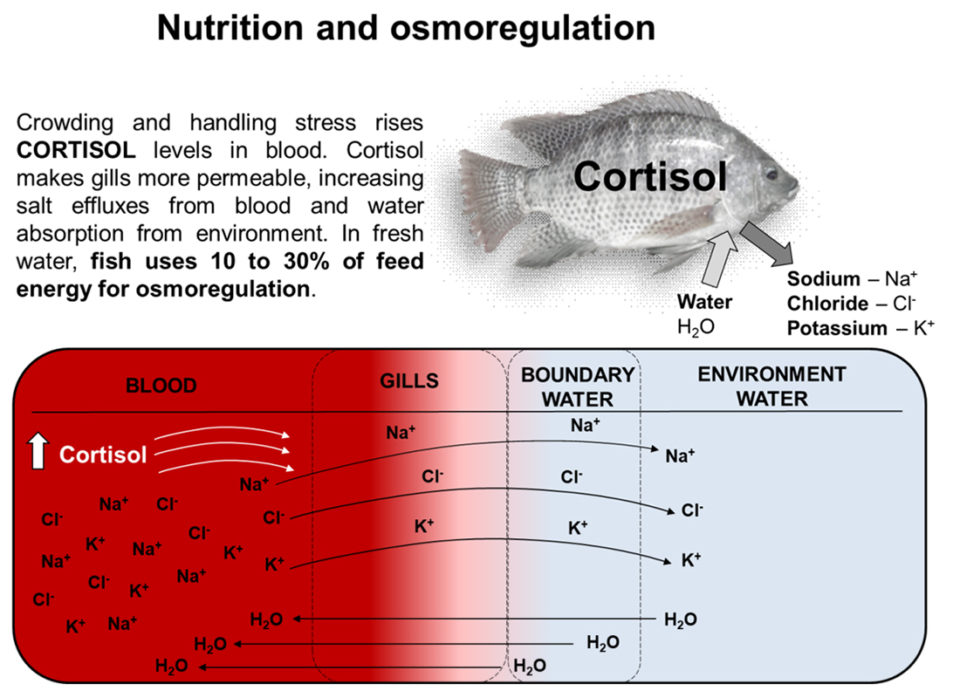

In freshwater, tilapias are continually absorbing water and losing salts (sodium, chloride and potassium) through the gills. The salts are replenished through feed. When tilapia are farmed in cages, salt losses can be magnified due to a more intense stress (related to crowding and more aggressive and physical contacts during feeding) compared to pond or tank culture at lower stocking densities. Cortisol, a hormone associated with physiological stress response, increases the permeability of the branchial membranes to water and salts, augmenting the losses of salts and absorption of water (Fig. 1).

Through osmoregulation mechanisms, the fish tries to minimize water absorption and salt losses through its gills. Osmoregulation consumes around 10 to 30 percent of the food (feed) energy ingested by the fish. This may explain why tilapias gain 9 to 18 percent more weight in waters with salinity levels between 4 and 10 ppt compared to freshwater. The provision of a more suitable balance of electrolytes in the diet facilitates the replacement of lost salts and reduces the energy expenditure in osmoregulation, directing additional energy for growth and immunity strengthening of fish.

In field observations at a commercial tilapia farm in Brazil, tilapia (Oreochromis niloticus, Chitralada strain) fed commercial feeds which we balanced with additional sodium, chlorides, potassium and magnesium ions to compensate for an estimated ions losses, showed improved growth (12 to 15 percent, better feed efficiency (+14 to 19 percent), survival (+ 5 to 6.5 percent) and annual net yield (+26 to 44 percent) compared to tilapia fed the same commercial feed without the ionic supplementation (Table 2).

Kubitza, Tilapia nutrition, Table 2A

| Non-supplemented | Salt supplemented (Na, Cl, K & Mg) | Gain (%) |

|---|

Non-supplemented | Salt supplemented (Na, Cl, K & Mg) | Gain (%) | |

|---|---|---|---|

| Mean initial weight (g) | 158 | 148 | – |

| Mean final weight (g) | 776 | 673 | – |

| Avg. days growth | 158 | 119 | 32.3 |

| Avg. daily growth (g/day) | 3.93 | 4.41 | 12.1 |

| FCR (kg feed/kg gain) | 1.76 | 1.54 | 14.3 |

| Survival (%) | 93.1 | 99.1 | 6.5 |

| Biomass stocked (kg) | 149,426 | 156,171 | – |

| Biomass harvested (kg) | 684,577 | 705,326 | – |

| Volume of cages (m3) | 10,040 | 9,500 | – |

| Net yield (kg/m3/crop) | 53.3 | 57.8 | 8.4 |

| Annual net yield (kg/m3/year) | 123.4 | 177.1 | 43.5 |

Kubitza, Tilapia nutrition, Table 2B

| Non-supplemented | Salt supplemented (Na, Cl, K & Mg) | Gain (%) |

|---|

Non-supplemented | Salt supplemented (Na, Cl, K & Mg) | Gain (%) | |

|---|---|---|---|

| Mean initial weight (g) | 176 | 149 | – |

| Mean final weight (g) | 790 | 752 | – |

| Avg. days growth | 161 | 130 | 23.3 |

| Avg. daily growth (g/day) | 3.82 | 4.41 | 15.4 |

| FCR (kg feed/kg gain) | 1.88 | 1.58 | 19.0 |

| Survival (%) | 92.3 | 97.1 | 5.2 |

| Biomass stocked (kg) | 164,350 | 353,270 | – |

| Biomass harvested (kg) | 679,517 | 1,729,560 | – |

| Volume of cages (m3) | 12,560 | 32,900 | – |

| Net yield (kg/m3/crop) | 41.0 | 41.8 | 1.9 |

| Annual net yield (kg/m3/year) | 93.2 | 117.1 | 25.6 |

Other authors reported similar results. Cnaani et al. (2010) also found 17 to 20 percent better growth in hybrid tilapia (O. niloticus xO. aureus) fed diets supplemented with 2 and 3 percent NaCl than fish fed diets without salt addition. Hallali et al (2018) observed 47 percent increase in growth as well as higher dry matter, lipids and protein digestibility in hybrid tilapia (O. niloticus x O. aureus) fed feeds supplemented with 5 percent NaCl compared to tilapia fed feeds without NaCl supplementation. A study conducted in China with hybrid tilapia (O. niloticus x O. aureus) showed that 0.5 to 2 percent Na supplementation in purified diets (equivalent to nearly 1,25 to 5 percent NaCl inclusion) increased the weight gain of fish by 17 percent and decreased feed conversion ratio by 16 percent, compared to the use of feed without salt supplementation (Shiau and Lu, 2004). Adding more salt over 5 percent did not improve fish performance any further. Shiau and Hsieh (2001) also determined the need to include 0.3 percent potassium in diets for juvenile tilapia. This equates to a 0.5 percent dietary inclusion of potassium chloride.

Amino acids and protein levels in tilapia feeds

Ten amino acids are considered essential to most animals, including fish. Thus, they need to be present in balanced quantities in the feeds for intensive tilapia production (Table 3). Once the essential amino acid requirements are fulfilled, Nile tilapia has better growth when feeds contain 30 to 45 percent crude protein (CP), depending on the stage of development.

Kubitza, Tilapia nutrition, Table 3

| Amino acids | NRC (2011) | Santiago and Lovell (1988) | Brazilian tables for tilapia (2010) |

|---|

Amino acids | NRC (2011) | Santiago and Lovell (1988) | Brazilian tables for tilapia (2010) |

|---|---|---|---|

| Lysine | 5.0 - 5.7 | 5.1 | 5.8 |

| Methionine | 2.2 - 3.1 | 2.7 | 2.0 |

| Methionine + cystine | 2.3 - 4.0 | 3.2 | 3.5 |

| Threonine | 2.0 - 3.9 | 3.8 | 4.5 |

| Tryptophan | 0.5 - 1.0 | 1.0 | 1.1 |

| Phenylalanine + tyrosine | 5.0 - 6.5 | 5.5 | 6.3 |

| Arginine | 4.2 - 6.0 | 4.2 | 4.8 |

| Histidine | 1.5 - 2.1 | 1.7 | 2.0 |

| Isoleucine | 2.2 - 3.1 | 3.1 | 3.5 |

| Leucine | 3.3 - 4.1 | 3.4 | 3.8 |

| Valine | 2.8 - 3.6 | 2.8 | 3.2 |

Dietary protein levels for tilapia post-larvae and fingerlings (up to 30 grams)

In controlled laboratory conditions, tilapia growth during the initial phases of sex reversal is maximized using feeds with protein levels between 40 and 45 percent (Table 4). However, field results generally give superior performance using powered feeds with 50 to 55 percent CP compared to 40 to 45 percent CP in this phase. This has more to do with the stability of the powdered feeds on the surface of the water than with the higher levels of protein in the feed.

To formulate feeds with 50 to 55 percent CP, larger quantities of high protein animal meals are needed (i.e., fish, blood, feathers, poultry offal, meat and bone, and others). Animal meals are less dense than plant protein meals. For this reason, powdered starter feeds with protein levels of 50 to 55 percent usually remain longer on the surface of the water, as they are lighter and more water stable than lower protein powdered feeds. This buoyancy favors the consumption by the post-larvae and small fry before too much feed dissolves in the water.

Kubitza, Tilapia nutrition, Table 4

| Starting weight (g) | Crude protein (%) | Reference |

|---|

Starting weight (g) | Crude protein (%) | Reference |

|---|---|---|

| 0.012 | 45 | El-Sayed e Teshima 1992 |

| 0.012 to 0.3 | 41 | Hayashi et al 2002 |

| 0.4 | 30 | Furuya et al 1996 |

| 0.5 | 40 | Al Hafedh 1999 |

| 0.8 | 40 | Siddiqui et al 1998 |

| 1.0 | 34-36 | De Silva et al 1989 |

| 2.4 | 35 | Abdelghany 2000 |

| 3.5 | 30 | Wang et al 1985 |

| 8.0 | 38 | Kaushik et al 1995 |

Dietary protein levels in pre-grow-out and grow-out feeds (fish over 30 grams)

Most tilapia farmers use feeds with 32 to 35 percent CP in the pre-grow-out (30 to 200 grams) and grow-out (above to 200 grams up to 2 kg). Some farmers use 28 percent CP feeds in an attempt to reduce feed cost. However, feeds with low protein levels delay growth, reduce feed efficiency, build up more visceral fat and worsen carcass (body) conformation. As a result, increased production cost and reduced fillet (processing) yield. In Brazil, some tilapia cage farmers are using feeds with higher protein levels (35 to 40 percent CP with 8 to 10 percent fat – higher nutrient feeds) to produce tilapia up to 1.0 to 2.0 kg.

Higher nutrient feeds shorten the growout phase by 30 to 60 days, increase annual net yield and productivity, improve feed conversion (1.2 to 1.3 compared to 1.5 to 1.7 with feeds with 32 percent CP), and minimize the risk of disease outbreak. Other observed benefits were lower numbers of dead fish collected from cages daily, higher processing yield (due to less visceral fat and better developed dorsal muscles) and less rupture in the fillets. The sum of these benefits usually overcompensates for the higher price of 35 to 40 percent CP feeds.

In studies conducted in China with GIFT Nile tilapia, maximum weight gain and feed efficiency at 28 and 30 degrees-C were attained with a 40 percent CP feed (Qiang et al., 2012). The expression of growth factors (IGF – “insulin growth factor”) in the blood and liver of the fish was maximum at 30 degrees-C. Fish that were maintained at 28 degrees-C and fed diets containing 38 percent CP had higher survival after challenge with the pathogenic bacterium Streptococcus iniae. At a temperature of 29.4 degrees-C, tilapia fed a 42 percent CP feed showed higher blood counts of erythrocytes and leukocyte, and higher levels of hemoglobin compared to fish fed lower protein levels in their diet (Qiang et al 2013).

These studies reinforce the benefits of using high protein diets for tilapia in cages, especially during the periods of high temperatures (above 29 degrees-C) that favors the occurrence of bacterial infections. At temperatures above 29 degrees-C, fish farmers usually reduce feed allowance to minimize mortalities due to bacterial disease, wasting the tilapia’s growth potential at such higher temperatures. Tilapia farmers that use high nutrient feeds (35 to 40 percent CP; 8 to 10 percent fat) in these periods have observed that, even reducing the feeding rates by 20 to 30 percent, the weight gain is maintained or even improved compared to feeding 32 percent CP feeds at normal feeding rates.

The choice of feeds to be used is something very particular to each farmer. But these decisions should not be made solely based on the price of the feed bag. All possible gains discussed above and that can affect the economic outcome of the farm and processing plants should be considered.

Essential fatty acids (EFAs)

Fatty acids (FAs) are the forming units of lipids (oils and fats). Oils (vegetable and fish oils) are liquid at room temperature, as they contain a greater amount of long-chain FAs (18 or more carbon atoms) and with a greater number of double bonds, i.e., the so called polyunsaturated FAs (FAs of the omega-6 and omega-3 families). Fats, such as animal lards (beef tallow), are solid at room temperature because they predominantly contain short chains of 18 or less carbon atoms, saturated (no double bonds) and a few monounsaturated (only one double bond) fatty acids. Essential fatty acids (EFAs) are the fatty acids that animals cannot synthesize and, therefore, has to be provided through feed. Tilapia has a requirement for omega-6 FAs (about 1 percent of feed), while the omega-3 FAs has not yet been demonstrated essential.

In addition to being sources of EFAs, lipids are a concentrated and highly available energy source to fish. Tilapia responds well to the inclusion of oils and fats in its diet. Vegetable oils (soybean oil) and poultry fats (which have a FA composition very similar to that of vegetable oils) are sources of FAs widely used in feeds. Beef tallow, constituted mainly by saturated FAs, is of little nutritional benefit to tilapia. Studies showed that the inclusion of beef tallow to feed impaired growth, feed efficiency, protein utilization, survival and immune response of juvenile tilapia.

Surprisingly, however, juvenile tilapia fed diets supplemented with beef tallow showed improved survival after a bacterial (Streptococcus iniae) infection, compared to fish fed diets containing corn, menhaden or linseed oil. Ferreira et al (2015) also added 5 percent of different lipid sources in feed for tilapia and found no differences in fish performance and survival during the feeding period. However, tilapia fed on diets supplemented with soybean oil had higher survival (56 percent) after challenged intraperitoneally with Streptococcus agalactiae, when compared to fish fed diets supplemented with linseed, marine fish, corn or olive oils (28, 22, 13 and 0 percent, respectively).

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Fernando Kubitza, Ph.D.

Acqua Imagem Services in Aquaculture

Jundiaí, SP, Brazil

Related Posts

Health & Welfare

Aiding gut health with a natural growth promotor

A study with Nile tilapia conducted in commercial production cages in Brazil showed the potential – in the absence of major disease threats – of a commercial, natural growth promotor that modulates the microbiota (inhibiting growth of pathogenic bacteria and promoting growth of beneficial bacteria) and inhibits quorum sensing.

Aquafeeds

Animal byproduct concentrates useful tools in formulation

With the market volatility of fishmeal, as well as rising sustainability concerns, the aquaculture industry is seeking sources of protein, such as animal byproduct concentrates, to substitute for fishmeal.

Aquafeeds

Analyzing the hydrostability of shrimp feeds

The physical integrity and nutrient leaching of shrimp aquafeeds are important aspects in their quality control. The water stability of shrimp aquafeeds is often evaluated in various subjective manners. This analytical procedure provides a baseline for the aquafeed manufacturer to assess product quality.

Aquafeeds

Aquaculture feed producer Evergreen wins F3 Challenge

The inaugural F3 Challenge sought to drive innovation in the aquafeed sector and reduce aquaculture's reliance on marine ingredients like fishmeal and fish oil.