Intensive management practices can significantly improve seed productivity

Producing tilapia seed is relatively easy, as all tilapia species mature early (in four to six months) and reproduce year-round under suitable environmental conditions. They produce large eggs and exhibit a high level of parental care that ensures high larval survival. However, tilapia females spawn asynchronously, producing only about 2,000 eggs per clutch. Tilapia hatchery operators, therefore, often run into low seed quantity and quality problems. Advances made by tilapia researchers are now addressing these problems.

Much of the following discussion is drawn from research conducted at the Asian Institute of Technology, which also provides consultation and training in tilapia hatchery management.

Traditional seed production

The simplest tilapia seed production system is the one in which fingerlings from natural reproduction, obtained as byproducts of tilapia grow-out systems, are sold or used as seedstock. A more intensive, widely practiced form of traditional seed production is the use of separate breeding ponds. Broodstock are maintained in these 0.01- to 0.1-ha ponds, where fry and fingerlings are periodically netted out.

The latter system is far more productive than the former. However, there are a number of problems associated with these systems.

Inadequate recruitment control

Uncontrolled reproduction results in overpopulation, which slows down growth and inhibits reproduction. In pond breeding systems, fry output normally increases rapidly after broodfish are stocked. It decreases gradually because it is impossible to harvest all the fry released. Ponds are quickly overpopulated with recruits from early spawns, resulting in increased competition for food and space, and gradual deterioration in water quality.

Asynchronous spawning, cannibalism, and predation

As spawning is not synchronous but continuous, high variation in size among fry is obvious. This occurs even among the same age fry because of inadequate food availability.

Cannibalism occurs among fry of various sizes, and predation by parent stock, other fish, birds, and other animals present in the system is common. The most serious predation problem occurs in the presence of carnivorous fish (e.g., snake head, catfish, sea bass, etc.), which may completely eliminate fry in breeding ponds.

Cost of parental care

The time and energy spent in parental care is another cause of lowered productivity in seed production systems. Oreochromis females typically spend about a week mouth brooding, while feeding little or none. As a result, they need about two weeks of reconditioning before spawning again. Any reduction in the mouth brooding and/or reconditioning period increases broodstock productivity.

Demand for all-male seedstock

As tilapia grow-out systems intensify, demand for all-male fry or fingerlings increases. Commercial grow-out farmers prefer all-male seed stock in order to avoid unwanted reproduction in the system. More importantly, they can take advantage of the faster growth of males as compared to females. All-male stocks, therefore, give rise to larger fish of uniform size that fetch higher market prices.

Tilapia sex is determined in the first few weeks after hatching, during which it can be influenced by administering androgens like methyltestosterone. The most reliable means of androgen administration is via feed. Feed mixed with the hormone must be fed as early as possible after the fish hatch, and it should be the main nutrient source for fry in order to deliver the androgens at the dosage necessary for sex reversal.

This requires fry to be separated from their mothers as early as possible and incubated separately. There are other methods of producing allmale seed stock, e.g., genetic manipulation, hybridization, and hand sexing. However, these methods are somewhat less reliable for commercialscale production.

Improving productivity through broodstock management

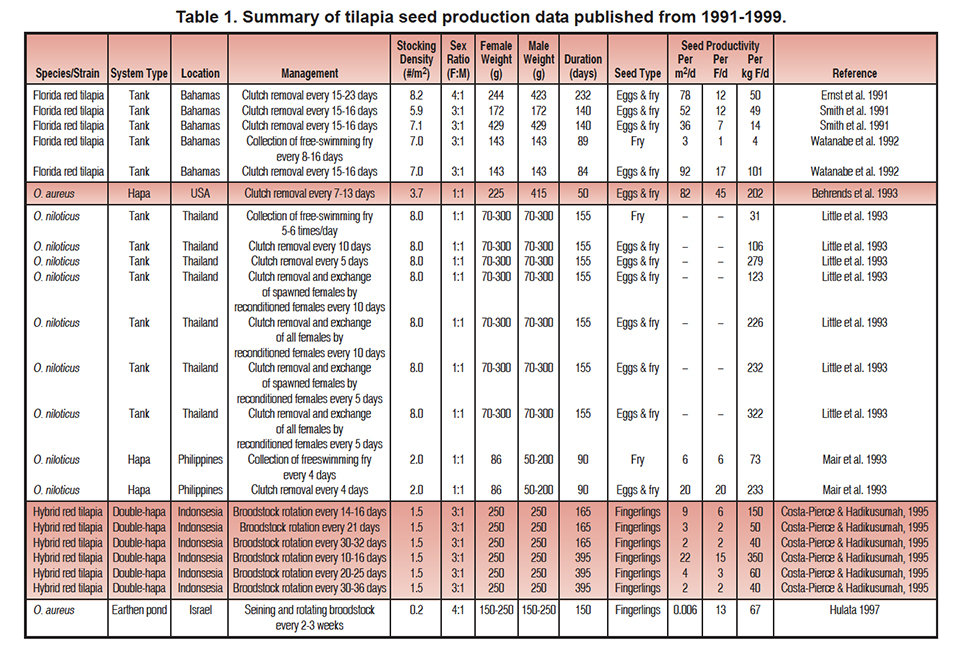

Ongoing international research on tilapia broodstock management has yielded a variety of productivity-enhancing techniques. As referenced in Table 1, even low-tech approaches have proven effective.

Broodstock size/age

Larger tilapia females produce more and bigger eggs per batch. Smaller females spawn more frequently and generate more eggs per unit weight, resulting in more eggs of smaller size.

Various authors have reported that breeding ponds stocked with smaller tilapia produce more fry than ponds stocked with larger tilapia. In Thailand, large commercial hatcheries use broodstock starting at 6 months of age (about 80 grams weight) and replace them with new batches after two or three years. In Israel, some farmers consider second-year, 150- to 250-gram females the most productive animals, and replace them every year.

As male tilapias are aggressive and territorial in habit, larger, dominant males control most of the spawning activities. This results in many unspawned females, or spawned fish with unfertilized eggs. Thus, uniformity in broodfish size is very important. Hatchery operators should consider both age and size as criteria for selecting broodstock, to avoid inheritance of slow growth trait.

Sex ratio and stocking density

A sex ratio of 3:1 (female:male) is commonly used by tilapia hatchery operators. However, lower ratios typically result in higher seed production, probably due to the availability of more mature males per female.

Most commercial hatcheries in Thailand that have adopted the use of hapas – net cages – in ponds maintain a 1:1 sex ratio to ensure high spawning and fertilization rates. They stock 6 fish per square meter of hapa suspended in inorganically fertilized ponds and provide supplementary feeding. The density can be doubled in tanks when complete feeds are provided.

Clutch removal

Mouth brooding is one of the main causes of reduced seed productivity. Females typically spend 10 to 15 days incubating eggs and caring for fry. They barely eat during this period, so they require another five to 10 days to recondition their ovaries.

Removal of eggs or newly hatched fry from the mouths of female Oreochromis helps them to quickly regain lost energy and become available for the next spawning cycle. Collection of eggs and yolk-sac fry from a large number of females at regular intervals – followed by artificial incubation and larval rearing – allows grouping of fry by age, resulting in more uniformity in fry size. This enhances the effectiveness of hormonal sex-reversal and reduces cannibalism.

However, the clutch-removal method is labor-intensive and requires periodic handling of broodfish. Broodfish are, therefore, kept in hapas, which can be of any size and are easily set up in ponds, lakes, or reservoirs. For example, a 40-square-meter hapa can be used to hold broodfish and produce 3,000 to 5,000 fry per day when the clutch-removal method is used.

A unique hapa-based broodfish management system commercialized in Thailand uses large (120 square meters) nylon hapas, each of which can hold 720 broodfish. About 80,000 eggs or yolksac fry are collected every five to seven days from each hapa. One of these hatcheries using AIT technology manages up to 60,000 working broodfish and sells up to 10 million fry per month.

Double-net hapas

Clutch removal is labor- and timeintensive, and requires facilities and techniques for the artificial incubation of eggs and larval rearing. A larvalrearing system has been developed in southeast Asia that uses double-net cages. The larger cage, constructed of fine, 2- to 3-mm-mesh net, contains a slightly smaller cage constructed of 4- mm-mesh net. Broodstock are placed in the inner cage and allowed to spawn. Periodically, the inner cage is lifted and moved out. When this happens, the fry swim through the larger mesh of the inner cage, but are retained within the fine-meshed outer cage. The fry continue feeding and growing in the outer cage, while the broodstock in the inner cage are placed in an empty outer cage.

By alternatively rotating the cages for breeding and nursing, a skillful hatchery operator can expect productivity levels higher than those of traditional fry production systems. A typical double-net system in the Philippines produced 29 fingerlings per female per day. Frequent broodstock rotations – every 14 to 16 days – can yield greater fry productivity than less-frequent rotations made up to 20 days apart.

Broodstock reconditioning

Tilapias spawn year-round under suitable environmental conditions, but a significant decrease in productivity occurs after three to four months of continuous spawning. At this time, males and females should be removed from the breeding system and stocked separately for a period of reconditioning. This improves seed productivity and also synchronizes spawning, even when clutch removal is practiced.

A more aggressive approach to broodstock conditioning has been developed at AIT, in which two or three female groups are rotated at 5- to 10- day intervals. Each female group is rested without males at a high density (18 to 20 fish per square meter) in a separate conditioning hapa, and fed high-quality feed after a spawning opportunity of five to seven days. This method improves seed productivity as well as spawning synchrony.

Broodstock nutrition and feeding

Feeds with greater than 40 percent protein content were previously thought to be necessary for tilapia broodstock. However, various authors have reported that these protein levels do not confer any specific advantage.

In a recent study, tilapia fed 32 percent and 40 percent crude protein levels grew and matured faster than those that were fed less than 25 percent crude protein. In another study, broodstock fed with 35 percent protein feeds reconditioned their ovaries faster than those fed less than 20 percent protein. In general, feeds with 28 percent to 32 percent crude protein appear to provide satisfactory broodstock performance.

Broodfish are typically fed at 1 percent to 3 percent biomass per day, divided into two or three equal meals. Large commercial tilapia hatcheries in Thailand that use hapas in fertilized ponds feed floating pellets with 25 percent to 27 percent protein, twice a day at 0.6 percent to 1.5 percent biomass per day.

Management of environmental factors

Optimum temperature for tilapia breeding is 28 to 30 degrees-C. A 50 percent reduction in seed output and some broodfish death occur in Thailand when summer temperatures in ponds exceed 35 degrees-C. Shading the culture system, sprinkling with cool water pumped from deeper parts of the ponds, and lifting or churning the cool water from pond bottoms using aerators are helpful measures.

In cold regions, tilapias are bred either inside greenhouses or in systems that use effluent water from thermal power plants to maintain optimum temperature. Low dissolved oxygen (less than 0.5 ppm) has negative impacts on quantity and quality of tilapia seed.

Excessive phytoplankton growth is undesirable in the breeding system. Inorganic fertilizer applications of 4 kg N per hectare per day and 2 kg P per hectare per day have been recommended in Thailand, instead of manure or other organic fertilizers.

Other management practices

Broodfish can be stunted up to 12 months at high density with restricted feeding before they are used for breeding. Stunted broodfish produce more seed when they are returned to normal feeding. This technique may also be used to manipulate seed supply, based on market demand for seed.

Various hormones have been tried to induce spawning in tilapia with some success. However, the use of hormone seems to be prohibitively expensive, as large numbers of broodfish are required to produce fry on a commercial scale.

Attempts were made to reduce aggressive behavior and social dominance of males by removing maxillary bones, but it did not help improve seed productivity. Provision of artificial nests (bricks, stones, etc.) in the breeding system helps to reduce social dominance, thereby improving seed productivity and quality.

Conclusions

Several significant advances have occurred in tilapia broodstock management in the past 10 years. Intensive management practices can significantly improve seed productivity. Even relatively simple practices, such as periodic replacement of broodstock, provide significant productivity gains.

(Editor’s Note: This article was originally published in the October 2000 print edition of the Global Aquaculture Advocate.)

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Authors

-

Ram C. Bhujel, Ph.D.

Aquaculture and Aquatic Res. Mgmt.

Asian Institute of Technology

P.O. Box 4, Klong Luang

Pathumthani 12120 Thailand -

Arul Victor Suresh, Ph.D.

Agribrands International, Inc.

9811 S. Forty Dr.

St. Louis, MO 63124-1103 USA

Tagged With

Related Posts

Health & Welfare

10 paths to low productivity and profitability with tilapia in sub-Saharan Africa

Tilapia culture in sub-Saharan Africa suffers from low productivity and profitability. A comprehensive management approach is needed to address the root causes.

Health & Welfare

A look at aquaculture in Guyana

With its large quantities of water and little industry to pollute it, Guyana has the potential to become a greater player in global aquaculture.

Responsibility

A helping hand to lend: UK aquaculture seeks to broaden its horizons

Aquaculture is an essential contributor to the world food security challenge, and every stakeholder has a role to play in the sector’s evolution, delegates were told at the recent Aquaculture’s Global Outlook: Embracing Internationality seminar in Edinburgh, Scotland.

Intelligence

A motive, and a market, for farmed fish in Mexico

Boasting ample areas for aquaculture and a robust domestic demand for seafood – not to mention its close proximity to the U.S. market – a land of opportunity lies in Mexico. Fish farming is primed to meet its potential south of the border.