Full Circle Biotechnology and HydroNeo collaborate on high-protein, low-carbon aquafeed

Norwegian-backed nutrient recapture company Full Circle Biotechnology has partnered with Thailand-based aquaculture technology startup HydroNeo to produce a high-protein, low-carbon additive for aquaculture feeds.

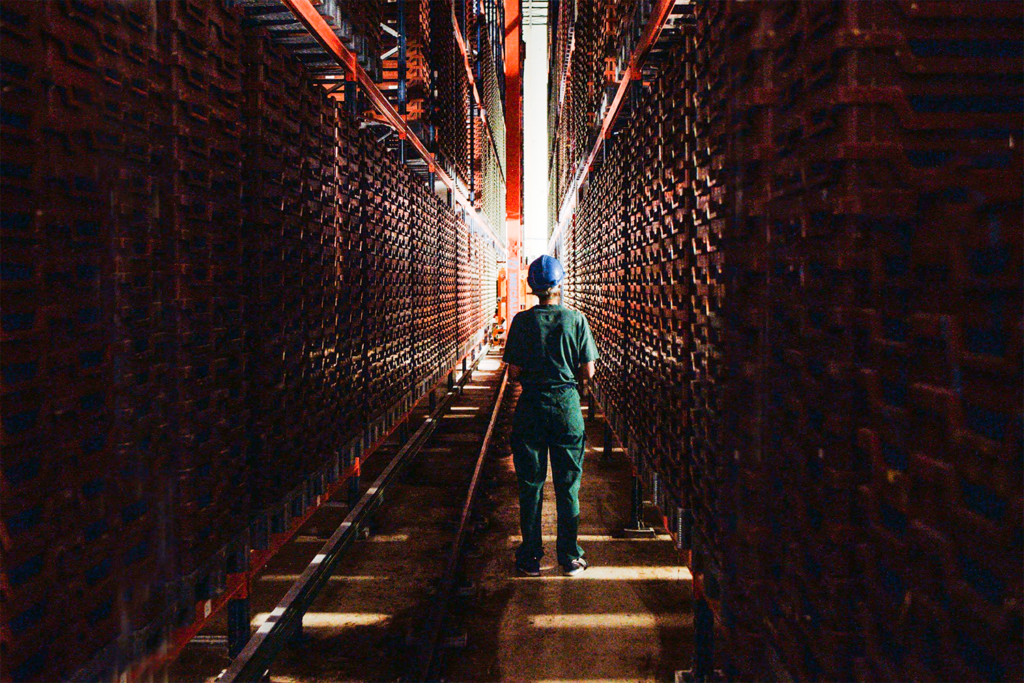

Full Circle has developed a waste-to-protein production system combining food waste with black soldier fly larvae and microbes that offers farmers the chance to cut both emissions and costs while providing an alternative to soy meal, fishmeal and other more carbon-intensive feed ingredients.

Its patent-pending technology allows agricultural waste to be upcycled. In a press statement, the company estimated that each year an estimated 380 million metric tons of greenhouse gas emissions are generated to transport and dispose of nutrient-rich food waste. Combining solid-state fermentation with black soldier fly production generates higher protein yields and less wastewater and requires less energy.

HydroNeo offers shrimp farmers an IoT system designed to continuously monitor water quality parameters, including DO (dissolved oxygen), pH and other factors, while providing real-time data and alerts. It also incorporates advanced automation features aimed at reducing energy.

“We are thrilled to be partnering with HydroNeo, to provide them with our unique aqua feed,” said Felix Collins, founder and MD of Full Circle Biotechnology. “This partnership not only generates a new revenue stream for both but enables each company to further innovate, as well as share industry insights and technical knowledge, leading us closer to our goal of reshaping the industry for the better.”

“Shrimp can be among the healthiest and most sustainable protein sources,” said Fabian Reusch, founder and MD of HydroNeo. “Being a farm technology provider with strong and trustful relationships with our customers, we are excited to introduce Full Circle Biotechnology’s innovative and sustainable feed products to them. Together, we can further increase the farm’s profitability while at the same time also animal welfare and sustainability.”

HydroNeo’s system integrates into existing farm infrastructure to provide comprehensive monitoring and control capabilities. Due to less environmental stress, the shrimps grow healthier and are more resilient towards potential diseases, increasing productivity. Through the automation feature, energy-intensive aeration can be lowered, reducing carbon emissions.

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

Related Posts

Aquafeeds

World’s largest fly factory attracting investors eyeing aquafeed expansion

A high-capacity black soldier fly factory puts Protix in position to ramp up production. Investors explain why they’re betting on the sector’s success.

Aquafeeds

Dutch companies keen on new shrimp feed that includes more insects and algae

Skretting Ecuador will produce a new shrimp feed that will partly replace two ingredients – fishmeal and fish oil – with insects and algae.

Aquafeeds

France has become innovation nation for insect production

With a thriving insect industry in France, new opportunities are emerging to advance aquaculture feeds and mitigate environmental challenges.

Aquafeeds

Fly guys: Canada opens the door for insect-based feed companies

The sci-fi flick “The Fly” warned about mixing flies and technology, but high-tech black soldier fly farmers are seizing a real opportunity in aquaculture.