Proposed Rule for Food Traceability looks good on paper but could be ‘burdensome’ for a global industry to implement

Each Atlantic salmon fillet shipped from the AquaBounty processing facility in Albany, Indiana, can be traced back to a specific batch of eggs from its hatcheries in Canada. Marking every single step in the seafood value chain is not just smart business or the latest marketing trend – it’s a requirement, one ultimately benefits end consumers in numerous ways.

“From a producer and processor standpoint, traceability allows us to track food through critical control points, making sure that we’re maintaining the [temperature, it’s pathogen-free] and other things we need to be concerned about from a food safety standpoint all the way through the supply chain,” said Mark Walton, CTO for AquaBounty. “We track our product all the way from birth to the [secondary processors’] loading dock.”

Creating a comprehensive digital footprint is part of AquaBounty’s commitment to seafood traceability – and it’s about to become law. The U.S. Congress passed the Food Safety Modernization Act (FSMA) in 2010 and it went into effect five years later. The original legislation contained seven rules that were designed to ensure the safety of the food supply and was hailed as “the most sweeping reform of our food safety laws in more than 70 years.”

Traceability was a key component of the original FDA-backed legislation. In 2021, the FDA added a FSMA Proposed Rule for Food Traceability. Section 204 establishes additional recordkeeping requirements for foods on the Food Traceability List, including all finfish species, crustaceans and bivalve mollusks, which would be applied to those who manufacture, process, pack and store the named foods.

The public comment period for the proposed rule ends on Feb. 22.

“These requirements define the set of key data elements associated with each critical tracking event that the FDA has determined must be recorded along the supply chain,” explained Bryan Hitchcock, executive director of the Global Food Traceability Center at the Institute of Food Technologies (IFT). “[FSMA] enables the FDA to focus more on preventing food safety problems rather than relying primarily on reacting to issues after they occur.”

Burden of proof

The regulation might make sense but implementing it will prove burdensome, according to Chip Terry, CEO and co-founder of BlueTrace.

“It’s going to be difficult for a lot of [operations], particularly small-to-midsize harvesters and distributors,” he said. “Keeping track of everything is painful right now and it’s going to get more painful and there are some companies that aren’t going to be able to make that transition and, if [the FDA] enforces it, it could mean fines, lawsuits or even being shut down.”

Joe Lasprogata, VP of new product development at Samuels Seafood, has devoted countless hours to figuring out how to trace the 30 million pounds of seafood processed and shipped from its Philadelphia headquarters so the seafood distributor will be compliant when the proposed rule goes into effect.

“One hundred percent traceability is a great concept but how are we going to do that?” he asked. “It effects everything we sell [and] it’s ridiculously complicated.”

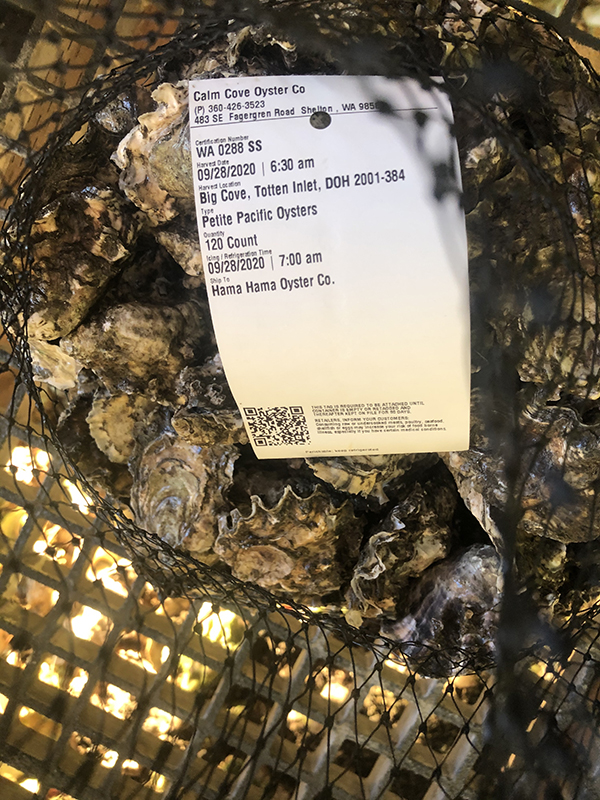

Samuels Seafood has been working with BlueTrace to test its shellfish management platform to create a digital system to track the 25 million oysters that move through the processor every year.

Currently, all the information on the shellfish tags is handwritten and, despite significant increases in the volume of their shipments, Lasprogata admitted that Samuels Seafood is still using the same antiquated system, which isn’t compliant with the digital recordkeeping requirements in the proposed FSMA rule.

Their beta test for digital shellfish documentation is set to launch in a few weeks. After that, Lasprogata will start figuring out how to track seafood that comes in from farms and boats all over the world. The process will be more complex because cuts are often commingled during processing.

At AquaBounty, records were digitized when the processing plant opened in Indiana in 2021. Information about the processed salmon cuts was added to the digital footprint that started in their Canadian hatcheries. AquaBounty, it should be noted, is the only company in the world to have a genetically modified organism approved for sale and consumption in the United States and Canada. These additional measures are “not a stretch because we’re already highly regulated,” Walton said.

There are often gaps in the digital footprint – or paper records instead of sharable, electronic records and those are the issues FSMA wants to correct.

For seafood imports, the proposed rule further defines traceability requirements, creates additional requirements for all producers to collect traceability data, and mandates a 24-hour turnaround to provide data to the FDA, according to Blake Harris, senior food traceability manager for IFT.

“[T]here are certainly operations that will be able to comply with [section 204] with minimal disruption, however some segments will require substantial coordination between supply chain partners to ensure compliance,” he said.

Lisa Weddig, VP of regulatory and technical affairs for the National Fisheries Institute, called the proposed rule “too strict for what’s needed.”

“Being such a global industry, the FDA needs to consider requirements from other countries,” she said. “If traceability [requirements] exist, that information should be used. We don’t want producers to have to provide six different types of data or data in different formats.”

NFI submitted comments on section 204 to the FDA during the public comment period. The comment stated, in part, “[T]he proposed rule in multiple respects exceeds the legal authority Congress established for FDA via FSMA, burdening seafood companies with requirements that…duplicate the information contained in separate records seafood companies already possess.”

One hundred percent traceability is a great concept but how are we going to do that?

Harris of IFT noted that seafood is a complicated commodity to trace, owing to supply chains that contain multiple layers of processors, packers and distribution channels for seafood that can be sourced from commercial vessels to shrimp ponds.

The Global Dialogue on Seafood Traceability created standards on the seafood industry’s key data elements and critical tracking events across the end-to-end supply as well as exchanging supply chain data across technology platforms. It’s the kind of guidance that Lasprogota has been seeking from the FDA. He’s concerned that the federal agency isn’t providing any assistance to support FSMA-compliance efforts.

Although the proposed rule, if adopted, isn’t slated to go into effect until 2023, Lasprogota added: “I can’t see [the FDA] flipping a switch and expecting everybody to be compliant.”

Change is coming

In the meantime, seafood producers and processors are trying to take steps toward digital traceability.

Shellfish producers may have the easiest time adapting thanks for the existing tagging system. Terry is currently working with 170 harvesters and 30 distributors to create a digital chain that uses an inexpensive thermal printer and food safe ink to print tags and transmit data via wireless devices via a Bluetooth connection; it allows traceability throughout the supply chain.

“Our technology strategy is to make it super easy for those seafood folks who aren’t technology-savvy and don’t want to become technology-savvy,” Terry said. “They just want something that works.”

It’s a start, he said, but it’s a long way from reaching small to midsize distributors.

Despite the onerous process to achieve compliance, Terry believes that full supply chain traceability does have advantages: He cites using QR codes for seamless ordering, checking digital time and temperature stamps throughout the supply chain to make sure oysters are safe to serve; and reducing seafood fraud. Walton agreed, adding, “We don’t see these things as burdens, we see them as part of what’s required to be a responsible seafood producer.”

Follow the Advocate on Twitter @GSA_Advocate

Now that you've reached the end of the article ...

… please consider supporting GSA’s mission to advance responsible seafood practices through education, advocacy and third-party assurances. The Advocate aims to document the evolution of responsible seafood practices and share the expansive knowledge of our vast network of contributors.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year.

Not a GSA member? Join us.

Author

-

Jodi Helmer

Jodi Helmer is a North Carolina-based journalist covering the business of food and farming.

Tagged With

Related Posts

Intelligence

Farmers trade Kansas cornfields for Florida clam beds

The Stones came to Florida without experience in clams and no ties to the fishing community. Their backgrounds in farming, however, are proving valuable.

Intelligence

Shellfishiency: Oyster farmers step boldly into the digital age

The online platform Oyster Tracker is designed to help oyster farmers keep track of inventory and make better use of their time on the water.

Innovation & Investment

Now Hatching: Millennial duo’s aquaculture analytics software

In the first startup profile of the inaugural Hatch cohort in Bergen, meet two young software developers who left Washington, D.C., for Norway and the power of personal connections to grow their aquaculture analytics business.

Responsibility

What threat do microplastics, a.k.a. ‘ocean hitchhikers’, pose to aquaculture?

A Trends in Microbiology paper posits that ocean microplastics could be a vector for pathogens, spreading antimicrobial-resistant genes.